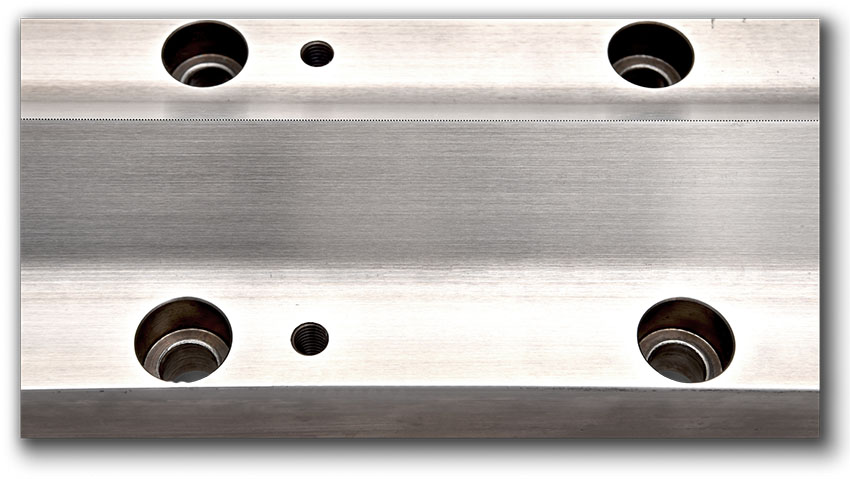

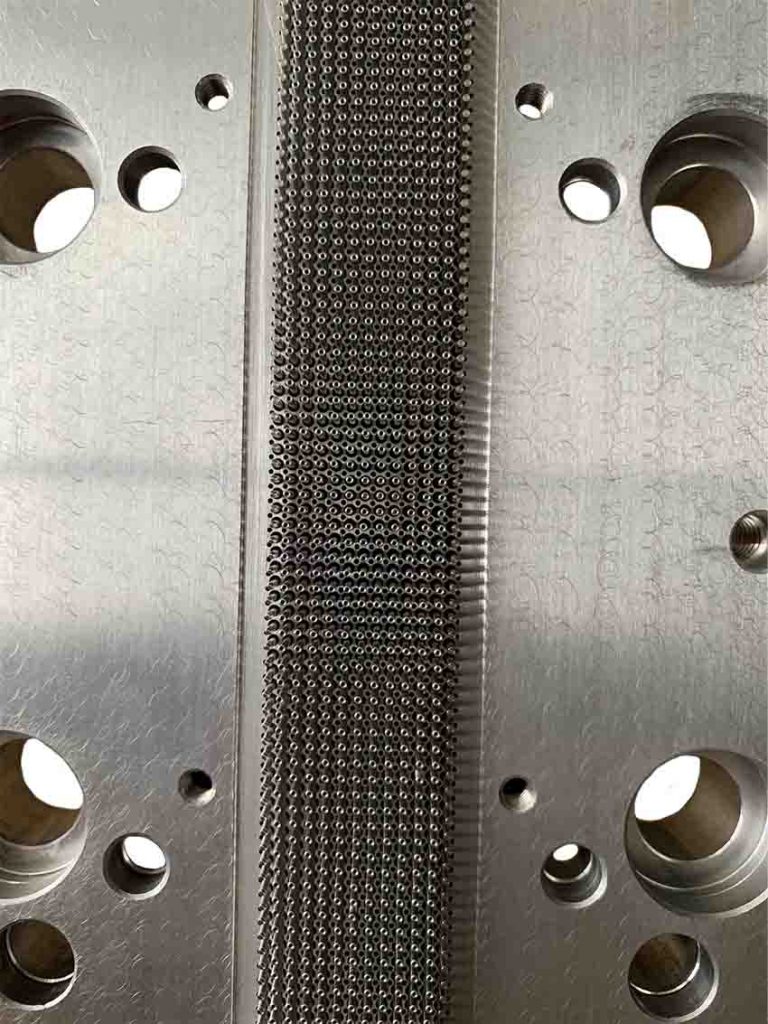

New Spinnerets is a company involved in the design and construction of spin packs and components for the synthetic fibers extrusion industry. The extrusion of synthetic fibres takes place through capillaries with sections of a few tenths of a millimetre, the know-how developed over the years allows us to guarantee tolerances in the order of 1 or 2 microns on the diameter of each capillary, often individual components have more than 40,000 capillaries.

Interview with Andrea Angelico, Managing Director at New Spinnerets.

Easy Engineering: What are the main areas of activity of the company?

Andrea Angelico: The company’s main areas of activity are design, production, quality control and R&D.

E.E: What’s the news about new products?

A.A: We are currently developing new products that offer maximum fibre performance using fully recycled and recyclable polymers.

E.E: What are the ranges of products?

A.A: New Spinnerets offers a wide range of products, although the core business remains the production of tailor made components and spin packs for extrusion plants, we offer several additional products to support their use and maintenance, such as cleaning and assembly sprays, polymer or metal seals, capillary mechanics cleaning tools, customised tooling and more. In addition, we offer reconditioning services for damaged or worn components, restoring the correct mechanical properties in order to maximise utilisation; our spinning packages often remain in production for over twenty years.

E.E: At what stage is the market where you are currently active?

A.A: The market is currently in a phase affected by rapid changes. Many resources are invested in research and development. Following the pandemic faced in recent years, where the medical hygiene industry was put in crisis to deal with the real need for overproduction, now that demand has recovered, all the challenges regarding sustainable conversion are resumed.

E.E: What can you tell us about market trends?

A.A: As anticipated, following the significant increase in demand that occurred between 2020 and 2021 and the consequent collapse that occurred in 2022 also caused by increases in raw material prices, the current trend demonstrates how priorities have also changed. Surely, we can highlight the two biggest consequences. The increase in demand has also generated an increase in competition, which is why the main leaders of the sector have an interest in developing new projects and products to identify themselves again at the top of the industry, the other issue inevitably concerns the enormous increases in production costs, as these are energy-intensive companies. The optimization of resources and developments in the production field are strictly necessary.

E.E: What are the most innovative products marketed?

A.A: Currently among the most innovative products marketed we have spin packs for the extrusion of bicomponent and tricomponent fibers in the Meltblown and Spunbond processes able to offer the maximum qualitative and quantitative yield, the combination of different materials responds to different needs, among which, is it is possible to obtain new fiber performances, reduce waste thanks to recycled materials, avoid the deterioration of polymers into microplastics harmful to humans and the environment, and so on.

E.E: What estimations do you have for 2023?

A.A: 2023 was a very important year for us, characterised by remarkable growth. We will certainly be able to realise a lot of satisfaction in the next six months. If, on the other hand, we were to analyse a little less specifically, I believe that in the short and medium term there will be no substantial revolutions in the market. We will probably have to wait until 2025 to be able to boast truly innovative products.