LiSEC is the partner for all-in-one-solutions for flat glass processors. With more than 60 years’ experience and 1.200 employees, the company is offering machines, software, and services worldwide.

Interview with Markus Jandl, Director Product Management and Joint Managing Director Glastech at LiSEC.

Easy Engineering: What are newest products in your range?

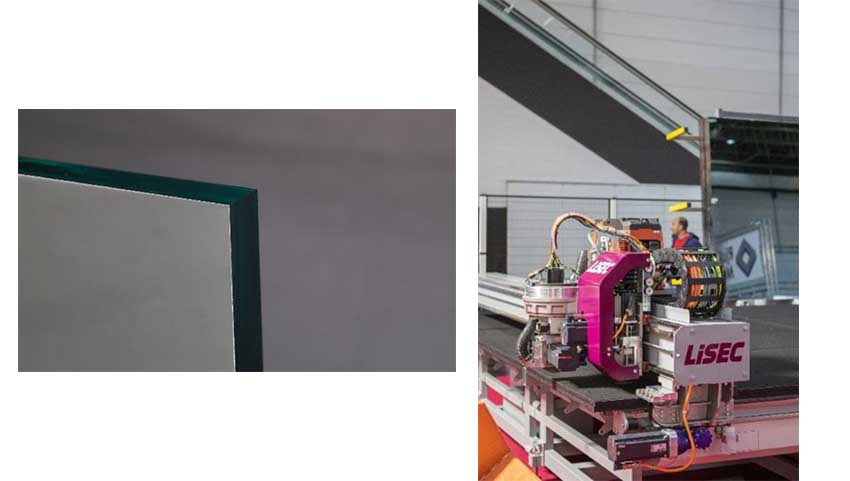

Markus Jandl: DSC-A Automatic glass cutting machine for float glass

The LiSEC direct cutting technology including the new cutting wheel holder ensures that the cutting wheel runs precisely. This ensures perfect cutting quality with high edge strength, even at high speeds of up to 160 m/min. Thanks to a highly stable bridge and a new grinding motor with up to 7000 rpm in combination with a significantly improved suction, the quality and speed of edge stripping is raised to a previously unattainable level. Therefore, efficient processing of coated glasses is possible without any problems.

Optimized commissioning

Previously, our cutting tables were divided into two parts and the cutting bridge was also delivered as a unit. Additional installation and setting work were necessary during installation. Thanks to an intelligent option to leave the cutting bridge installed rotated on the main module for transport, no cables must be terminated. Additional shipping and installation work at the customer are eliminated.

Individually configurable and high quality

The DSC-A can be flexibly configured and cutting edges can be created, that were previously considered “impossible” in the industry. Even with a glass thickness of 19 mm, there are almost no microcracks, damages, over- or underbreaks. The result is an edge with high strength and reduced hemming or grinding costs on subsequent edge processing systems.

RHF: Robot System for automatic frame mounting

The RHF consists of a six-axis articulated arm robot and the frame clamping system mounted on it. The frames are ideally prepared fully automatically. This means, that they are filled with desiccant, applied butyl by an automatic butyl extruder and then pressed onto the glass at the required position. The RHF enables fast and reliable frame installation and can handle a wide range of frame sizes.

LiSEC invented the clamping system, which can grab a frame from 350 × 350 mm to 2.500 × 2.500 mm. With this system, the accuracy and the speed of a rigid spacer line increases strongly. The RHF can execute all types of rigid spacers like aluminum, stainless steel, hybrid and plastic spacers.

Importance of the features for users

With the RHF we can meet all product requirements within a short cycle time. Another big advantage is the variable installation option, which allows the customer to position the RHF-A at several points in the line. The spacer line can also be individually adjusted depending on the space situation, so that it achieves the optimal result.

Robotersystem zum automatischen Rahmensetzen am Glas – LiSEC.com

Easy Engineering: Which are the most innovative / trending products and what special features do they have?

M.J: KSD: Vertical Edge seaming and grinding machine for glass with LiTEC Slider Technology

It is important to compensate for defects in the glass. As heart of the KSD, the LiTEC slider tool brings the flexibility of grinding belts to the V-shaped diamond tool. We have loosened the rigid connection between the tool itself and the holder. So, it can move on the holder itself and the two parts of the tool are flexible to each other. With a certain pressure on both sides, the tool swims on the glass edge and is 100% self-regulating the complete process.

The new LiTEC slider tool achieves perfect seaming quality even on/with:

- bad breaking quality

- slightly curved or damaged glass sheets

- misaligned laminated glass

- geometric inaccuracies

Importance for users

LiTEC Slider compensates poor cutting qualities or offsets in laminated glass. Additionally, it provides continuous seam, reduced waste, or breakage in the oven as well as reduced wear during further transport. Also very important is the easy usability with only one tool for all glass thicknesses.

E.E: How important are these features for the users in their work?

M.J: Small cracks / split-offs on the glass edge can have a big influence on later processes. The KSD LiTEC slider tool can compensate such glass edge faults and always guarantees a smooth grinding or seaming independent from former operator or glass processing influences. This is important for a stable product quality with a constant output of edge processed glass and less rejects.

E.E: How do your new products / services differ from others on the market?

M.J: LiSEC machines are designed for a long lifetime, optimized for a stable process with a high energy efficiency and less material consumption. Important points to achieve high productivity are: Highly automated machines with less operator influence and closed loop control devices, that take care about environmental influences (temperature or moisture) or fluctuation in the consumable materials (viscosity of sealing material during application).

LiSEC is the only company in the industry, who deliver the whole processing machines as well as the software. This is also a main advantage especially at green field projects where LiSEC supports the customer in the whole development process.

E.E: Tell us about research and development in your company.

M.J: R&D is very important for LiSEC and more than 7% of sales are invested, which is visible in more than 330 patents. It is our goal to deliver adequate processing machines for all main glass products. Ideas are not only created in our R&D center. All employees have the opportunity to bring their ideas and thoughts to decision-makers.

E.E: What impact has product innovation on your customers?

M.J: We often work with our customers to develop new machines or additional upgrades. Our customers know exactly what they need and what they expect from our development. Together we carry out prototype tests at the customer’s site and improve the production process for our customers.

E.E: What new products / solutions are you going to launch in the future?

M.J: At the Vitrum trade fair we showed an insulating glass line which applies thermoplastic spacers with our new cutting-edge. This ensures gas tightness of the units, observes minimum production tolerances, and allows a wide range of unit thicknesses with the shortest lead times.

Another new development is the PDL-A, a rotating device and platform for one double-sided glass storage rack (A-rack) with 180°C rotatability for uninterrupted glass removal by means of a glass removal robot. A recess in the substructure ensures that forklift trucks can drive underneath.

E.E: What industries do you think will grow in 2024?

M.J: Due to the energy crisis, we expect a shift from new buildings to renovations which requires new production lines with a better Ug value. On the other hand, finding qualified personnel is a global challenge and will encourage a higher level of automation. As an all-in-one-solution supplier, LiSEC supports its customers with innovative machines and software solutions.

E.E: What products/solutions do you provide for these industries?

M.J: The trend towards higher automation up to even unattended production is still a key requirement in almost all regions. In addition, evidence from the CO² balance to the circular economy and the presentation of concrete figures are becoming increasingly relevant for sales.

The longevity of the products will become increasingly important. Since the hardware and electronic components are usually the limiting factor for the service life of a system, the LiSEC LongLife department will continue to make a significant contribution with various upgrades in the future.