UST Umwelt-Systemtechnik was found 1991. Since 2004, the company is developing and producing systems for the disinfection of water. Those systems are generating electromagnetic waves in the ultraviolet spectrum (UV) with a focus on a wave length of 254 nanometres (nm). At this wave length bacteria, viruses and any other microorganisms are most effectively reduced.

Easy Engineering: What are the applications for UST’s systems?

UST: In the area of water treatment, UV-systems are used for multiple applications, for instance to disinfect drinking water, to improve waste water or to treat process water.

UST is focussing with its ULTRA V-systems on the disinfection of circulated water in cooling processes, typically used in cooling towers and air washers (https://www.ust-gera.de/en/water-disinfection/ultra-v-sales)

The evaporation of water in cooling towers is the easiest and cheapest way to dissipate large quantities of heat in industrial production facilities. Air washers provide a simple solution using water to clean and cool air for production sites such as semiconductor plants.

However, the water in those cooling circuit does require treatment to counter the biological growth as the water typically offers excellent conditions for bacteria to develop strongly in numbers.

E.E: What needs to be done to keep the water quality in a hygiene condition?

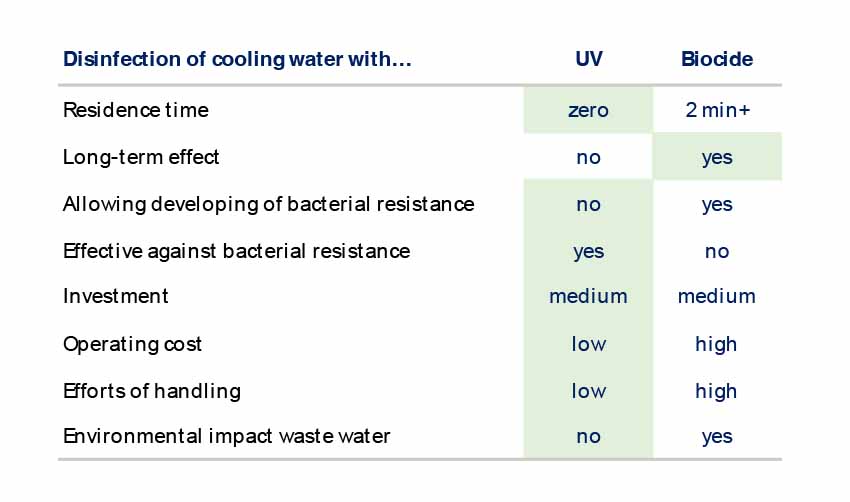

UST: Traditionally chemical disinfection substances, biocides, have been used to limit the growth of bacteria, with a special attention to those that are harmful, like Legionella. Biocides provide a useful solution, but it comes with a number of downsides as the below table displays. Maybe most importantly, the cost of using those chemical substances is high, both the investment for dosing systems and monitoring, as well as the operating cost for the constant consumption of the chemicals.

Over the last decade, UV-systems have been developing as a viable alternative to the chemical disinfection in cooling circuits. While the investment for an UV-system is similar to that of a dosing system, the operating cost are minimal and the effort of operating the UV-system can be made very simple.

E.E: What are newest products in your range?

UST: There are two general approaches to utilize UV-systems in a water circuit.

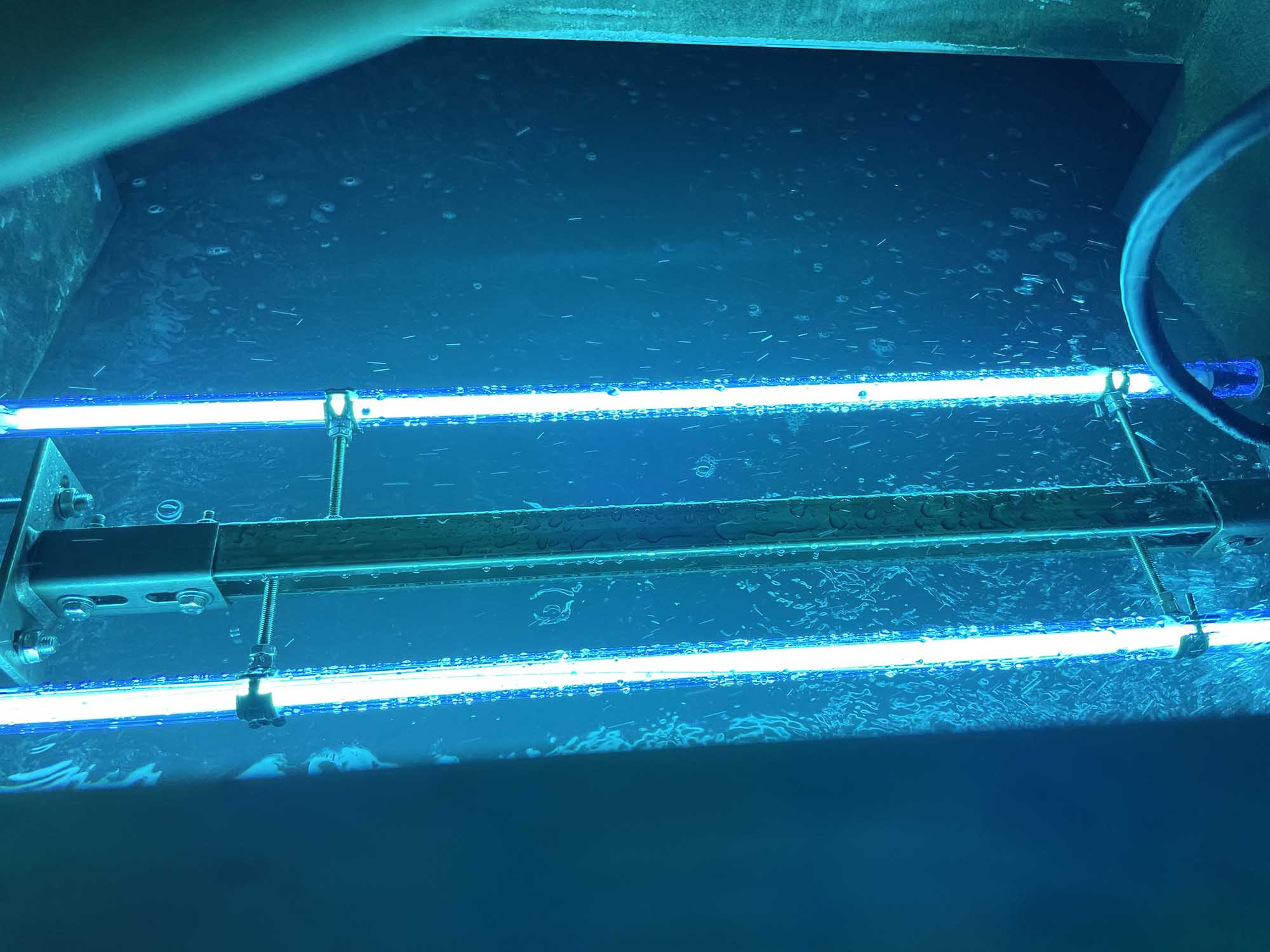

| In the classic setting a stainless-steel chamber, holding the lamp emitting the UV-radiation, is integrated into the water network. | During the past few years, we have been collecting very positive experiences with submersed UV-systems. With that approach the UV-emitter is directly integrated into the water reservoir. The stainless-steel chamber is not required which allows a reduction in production cost. Even more important is the higher impact on the microbiological reduction. |

| >>Picture to integrate: Pic01, subtitle: Example UV-system as flow through system, ULTRA V1.2k, stainless-steel chamber with 4 UV-lamps and a total performance of 1.200W for up to 100m³/h | >>Picture to integrate: Pic02, subtitle: Example of a submersed UV-system inside an air washer, ULTRA V300/MTS, with 2 UV-lamps and a total performance of 300W |

E.E: How does a submersed UV-system achieve the improved disinfection results?

UST: There are two main reasons for the stronger effect on the microbiology. Firstly, the UV-radiation can reach deeper into the water. Depending on the transmission of the water, the radiation is reduced over the distance in the water.

In UV-system with the UV-lamps inside the stainless-steel chamber the radiation is cut off when it reaches the inner side of the stainless-steel chamber. The distance in which a then very intense UV-radiation is used can be as short as 10mm.

Inside the water reservoir a submersed UV-lamp can, depending on the transmission of the water, still proof effective, if at a reduced performance.

E.E: And the 2nd reason?

UST: The reservoir in a water circuit is typically the place where bacteria find best conditions to grow. The temperatures, above 20°C, are favourable, with air and dust, biological material can enter the reservoir through openings. The waterflow is reduced, maybe stopped entirely at times. That gives the opportunity for microorganism to settle at the walls of the reservoir and form a biofilm.

Once the biofilm is present, it will grow under the conditions provided. The microorganisms of the biofilm will not pass the water treatment stages with the waterflow but it will contaminate the passing water increasingly.

A submersed UV-system does not only disinfect the water flowing through. It also keeps the reservoir in a hygiene condition. It prevents effectively microorganisms to settle at the walls and thereby reduces growth rate of the microorganism in the water.

>>Pictures to integrate: Pic03 & Pic04, subtitle: Example of a submersed UV-system inside the buffer tank of a cooling circuit. The before picture taken on the day of installation of the ULTRA V100, the after picture taken 2 months later.

E.E: What are the challenges for the use of submersed UV-systems?

UST: There are indeed some challenges with regards to two areas. One is safety. People should not be exposed to the UV-radiation of the disinfection systems. With systems that feature a stainless-steel chamber, it is safely prevented that people get in contact with UV. That is not always certain with submersed systems. Some safety measures should be introduced if not already in place. The water reservoir should be covered, for openings contact switches should be considered. Also protection equipment, like googles, should be accessible.

The second potential challenge may arise at the installation. Water reservoirs are sometimes hard to access. UV-systems with one or two meters at length may not find the required head room to be integrated into the water reservoir.

E.E: What is the innovation offered by UST’s systems?

UST: UST has gathered through its projects broad experiences that helps to offer UV-solutions that fit best to the requirements of our clients. Further we have played successfully with 3D-printing as a solution for our clients to provide individual configurations, quick and at low cost.

Further the numbers allowed us to form solutions that are easy to implement by the clients themselves. For instance, for standard industrial tanks of 0,5m³ – 10m³ we have developed readymade solutions that fit in size and style.

E.E: What is the outlook for 2024?

UST: Good engineering and high quality in production are at the base of the success of ULTRA V systems. Beyond that however, a number of global developments support an increasing demand:

The aim to reduce the environmental footprint has become part of the philosophy of most of the industrial companies

Enterprises drive towards simplification and automation of processes, may it be for the limited availability of qualified personnel, risk limitation or quality assurance

Monitoring operational cost is a given, cutting smartly is the current challenge for businesses.

ULTRA V systems in the cooling circuit limit the water consumption and allow for better quality of the water eventually discharged. The manual handling of hazardous substances is a constant risk that can be eliminated using UV for the disinfection. Operational cost of a ULTRA V tends to zero, while the dosing of biocide requires regular recharging.

Not everywhere in the industry the outlook might be positive for the next 12 to 18 months. As it is more the fear of an economic stalemate rather than an acute liquidity problem, investments considered helpful to improve general efficiency will not be curbed, while cutting operational cost will naturally be in focus. The ULTRA V business grew by almost 30% p.a since 2019, the conditions are such that this development is expected to continue for the coming year.