WiCKON Hightech, in the market since 2005, is focused on research, development and production of automated optical inspection systems (3D).

Interview with Roman Wieser, Founder & CEO of Wickon Hightech.

Easy Engineering: Wickon Hightech is known for its high-end automated optical inspection (AOI) solutions for industry. Could you give us an overview of the company?

Roman Wieser: Wickon Hightech is a global provider of high-end automated optical inspection (AOI) solutions. Since our founding in 2006, we have developed a wide range of products and services to optimize and secure the manufacturing processes of electronic assemblies. We focus on the automotive, regenerative energy, and healthcare industry, providing services such as 3D-AOI systems for fuel cell production and wire bonding inspection. We use the different technologies, for example, to create an inspection system that combines all the capabilities in one system for the verification of hearing aids. It monitors the wire bonding process, as well as the wobble circle of pins with 3D information, transparent glue dots, and weld seams.

E.E: According to market analysts, the market for AOI systems is constantly evolving and will grow strongly in the future. What factors are driving this development?

R.W: A key driver for the strong growth of the AOI systems market is global decarbonization, which is leading to an increasing demand for stable automation processes in various industries such as electronics, power engineering, medicine, and telecommunications. The transition from fossil fuels to renewable energy sources is a major challenge for the industry and requires a significant transformation of production facilities. Robust technologies are required to meet these demands, and this is where our AOI systems come in.

E.E: Wickon Hightech has developed a 3D inspection system for fuel cell production that can check the wet state in 3D. Can you tell us more about that?

R.W: Yes, that is correct. We have developed an inspection system that is able to inspect all common fuel cell paste prints in three dimensions, in the wet, dried, and sintered state. Compared to competing systems that can only inspect in 2D, we are able to offer a precise inspection technology that detects serial defects early and reduces scrap rates. We are proud to have equipped the world´s first fuel cell production lines with functional 3D inspection.

E.E: What are the advantages of your 3D inspection system for fuel cell production compared to conventional 2D systems?

R.W: Our 3D inspection system can detect wet and wavy surfaces in three dimensions using numerical aperture illumination. At the same time, it can produce both 3D and 2D images in a single scan. Using a high-resolution color camera unit, we can capture images up to 130 x 110 mm in just 0.6 seconds. Layer thicknesses between 5 and 30 µm can be easily imaged. Compared to 2D systems, we offer a much more accurate and comprehensive inspection capability.

E.E: In addition to fuel cell production, Wickon Hightech is also involved in the inspection of SiC chips for the electric car industry. What are the innovations in this field?

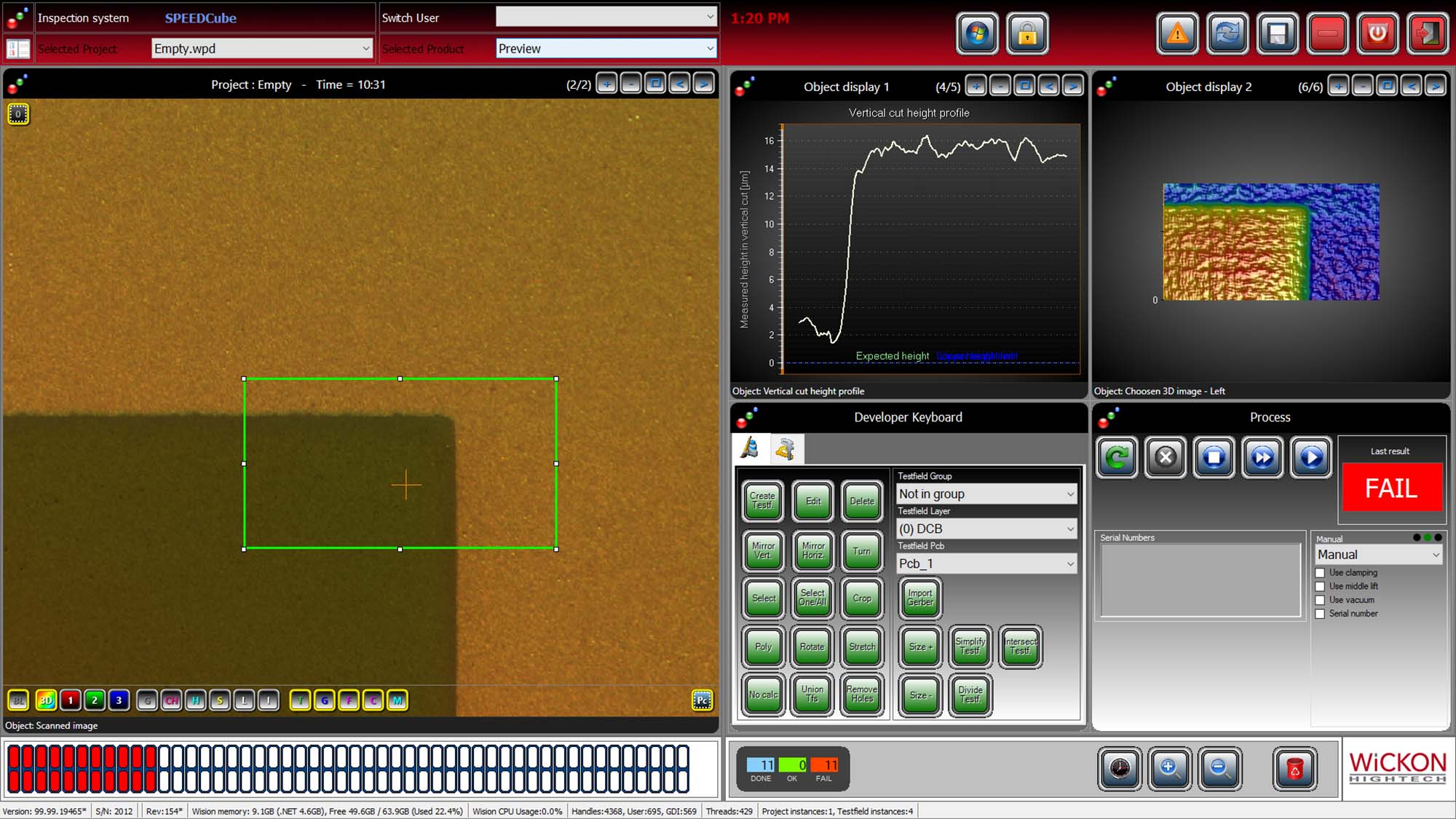

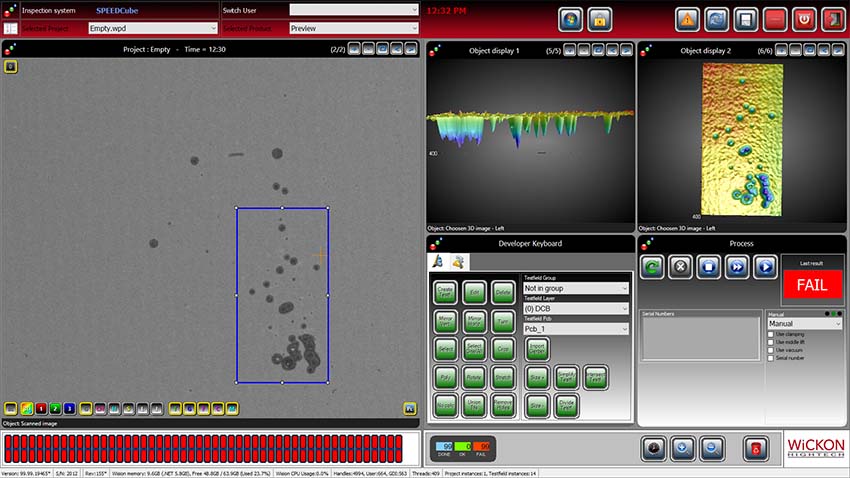

R.W: We have developed a metrology solution for the production of power modules where SiC chips are mounted on DCBs. The fastest camera on the world market generates high-resolution images with a width of 16,384 pixels at an acquisition speed of 40 to 50,000 lines per second. Each pixel is generated as a 16-bit value. This technology allows us to accurately capture 3D structures that depend on many parameters during processing. Our fully automated inspection systems can be seamlessly integrated into the production line enabling 3D or 2D inspection of surfaces with layer thicknesses down to 5 and 10 µm.

E.E: Will 3D technology replace 2D inspection?

R.W: That’s right, 3D inspection is a fast and precise measurement method that provides a much more accurate inspection result due to the additional information of the topology. At Wickon Hightech, we have improved our technology in recent years to the point where we no longer talk about 3D inspection but about 3D metrology. Many new products, especially in the field of energy conversion (fuel cells) or energy storage (solid-state batteries), rely on processes that apply very homogeneous and thin layers. Here we have solutions that can also fully map the process speeds.

E.E: What other products and developments can we expect from Wickon Hightech in the near future?

R.W: We are constantly working on new products and solutions to meet the changing needs of the industry. This year, we will be launching a 3D measuring probe that can inspect surfaces with a height difference of 1 mm in high resolution, with height variations in the range of 5µm or less. We have also developed a modular inspection head that can be integrated into existing equipment, enabling 3D imaging with variable image acquisition width and resolution. These innovations will further strengthen our position as a leading supplier of AOI systems.