Founded in 1995, OTTO-PRICKEN stands for construction, engineering, development and manufacturing of textile machines, customized engine building, tool making and forms of almost every kind of materials.

Interview with Michael Weger, CEO of OTTO-PRICKEN.

Easy Engineering: A brief description of the company and its activities.

Michael Weger: Here, besides a team of experience engineers and technicians, the latest 3D CAD/CAM technology is used above all.

A great number of different machines with the latest technology guarantee maximum flexibility and allow for an extremely effective workflow. Thus, an individual solution for each problem can be developed.

For several years, we have been providing innovative products in the textile industry for tailor-made solutions and with the focus of saving resources.

E.E: What are the main areas of activity of the company?

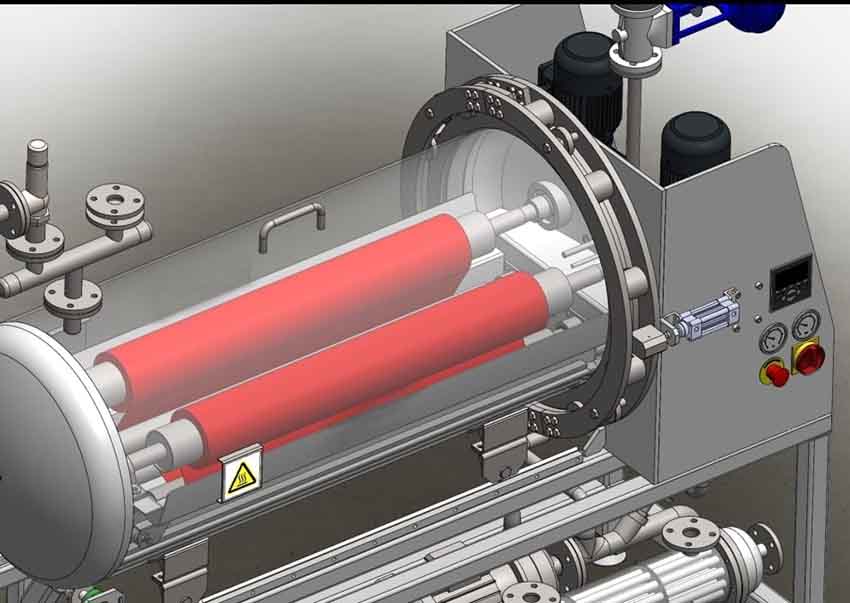

M.W: Our main activity is the manufacture of Jigger dyeing machines and laboratory machines for the textile industry

E.E: What’s the news about new products?

M.W: Our high tech igger feature the latest jigger drive and process technology. This means that the entire dyeing process runs automatically and the consumption of water, electricity, steam and chemicals is calculated and recorded.

This is how we create the RIGHT FIRST TIME DYEING effect.

E.E: What are the ranges of products?

M.W: For the Jigger dyeing process, we cover the entire range from laboratory to production.

This means we are the only Jigger producer worldwide for laboratory, sample and production Jigger in the atmospheric and high temperature range.

Incidentally, it should be mentioned that our HIGH TECH Jigger are able to dyeing the most difficult and complex woven goods. We can even treat very thin goods of 20g/m² without any problems

E.E: At what stage is the market where you are currently active?

M.W: Now the textile market is constantly changing. Of course, countries like China, Bangladesh, India, Turkey and Pakistan are the main markets. We are also active there. But we also have a regular customer base in Europe, South America and Africa

E.E: What can you tell us about market trends?

M.W: The trend is to get a “green image” and to use resources more sensibly.

I believe that many textile dyers have understood that resources are not endless and that we have to protect our environment. We have to take responsibility here.

It is therefore also urgently necessary to replace cheap machines that have extremely high consumption

E.E: What are the most innovative products marketed?

M.W: Machines that consume reduced energy.

Machines that achieve a liquor ratio of 1:2 and analyze consumption and processes.

Intelligent machines that avoid errors and recognize errors in good time. This is achieved with the latest technology, precisely coordinated software, high-end sensors and, of course, experience

E.E: What estimations do you have for 2023?

M.W: The year 2023 is a difficult year for many companies. War, energy crises and supply chain disruptions.

You can no longer plan for the long term. Companies have to reposition themselves and be able to react quickly.

So far, we have done everything very well and we will have a very good year in 2023. I don’t know what 2024 will bring us. But we think positively and have learned to be able to react quickly. Thanks to our team which we are proud of. Our team is our company’s capital and we value that.