Pantostamp is a consolidated reality in the injection mold industry. Founded in 1976 by Bernardo Scalici that decides to undertake the business venture producing special parts for injection molds.

Already after a few years, the company sees its growth in the complete production of injection molds for plastics.

Today Pantostamp is a supplier partner assisting the customer during the entire production process, from the design to the beginning of the production with the mold, establishing itself as a protagonist with the top companies of the molding industry.

Easy Engineering: What are the main areas of activity of the company?

Pantostamp: We operate in the pharmaceutical and spray market, for which we produce molds for components such pumps and dispensers of various kinds. This industrial sector usually requires high operational precision, given the complexity and the small size of some products. The required molds must also be in able to work in highly aseptic environments such as, for example, clean rooms.

Another important market for us is the cosmetics sector that has always been in continuous growth and development. In this compound Pantostamp guarantees the use of specific and certified materials, heat and surface treatments dedicated and the use of technologies that allow complex parting lines with very high quality. We also pay big attention in the surface finishing of the molded parts, to achieve excellent aesthetic results.

E.E: What’s the news about new products?

Pantostamp: Research with new materials, reduce cycle time and energy consumption, are the subject of some political values that Pantostamp offers to its customer.

Product development is increasingly the result of upstream activities of executive cooperation; the team of specialists and the ability to interact effectively are the basic components of our and our clients success.

E.E: What are the ranges of products?

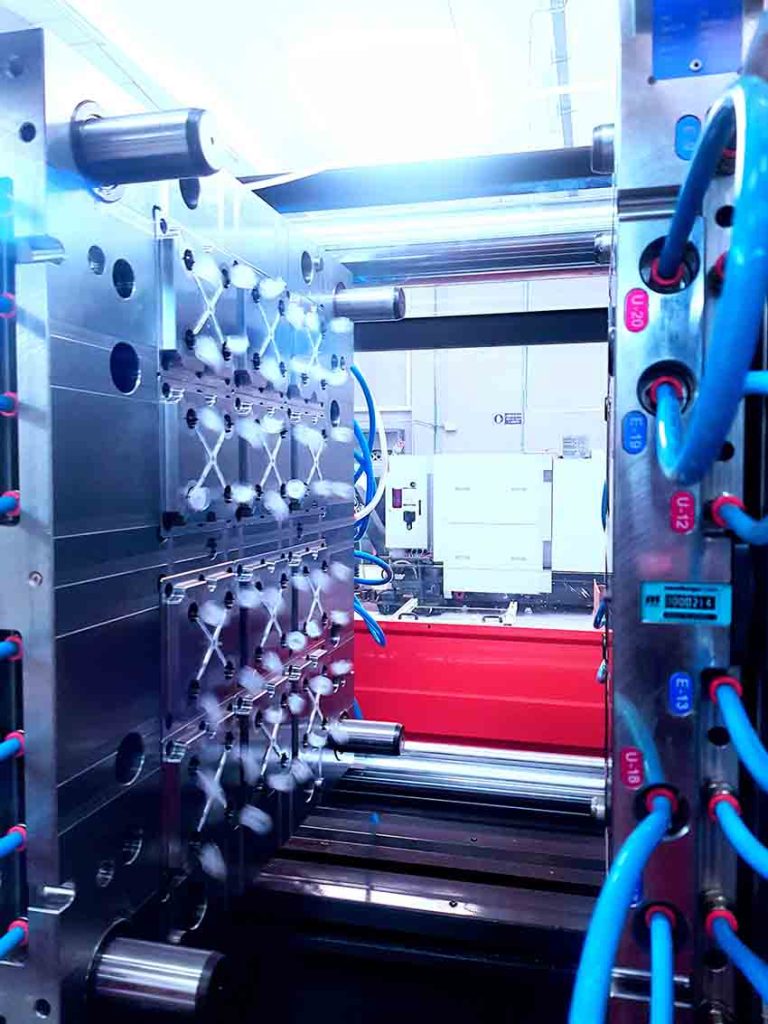

Pantostamp: Pantostamp for the last two decades has focused its core business in the packaging sector, designing and producing multicavity molds for high production volume.

The main areas of our mold production are Pharma, Spray, Personal care and Cosmetic.

In the Pharma and Spray sector we produce molds for pump components and dispensing actuator.

Regarding cosmetics and personal care tools for flip top caps, mascara and lip gloss components and cap and closure in general.

E.E: At what stage is the market where you are currently active?

Pantostamp: Then packaging market in general seems to be really active besides the crisis of the automotive sector that normally rules the economy.

E.E: What can you tell us about market trends?

Pantostamp: In these last few years Clients are orientated in the use of recycled resins and as toolmaker we are following this trend in the moldmaking.

E.E: What are the most innovative products marketed?

Pantostamp: No answer we follow our client request so we can’t really give an idea of innovative products

E.E: What estimations do you have for the rest of 2023?

Pantostamp: In these last 2 years 2022-2023 we are growing quite quickly and we can say that for 2023 the estimation will continue grow.