Easy Engineering: What new products / solutions do you have for your customers?

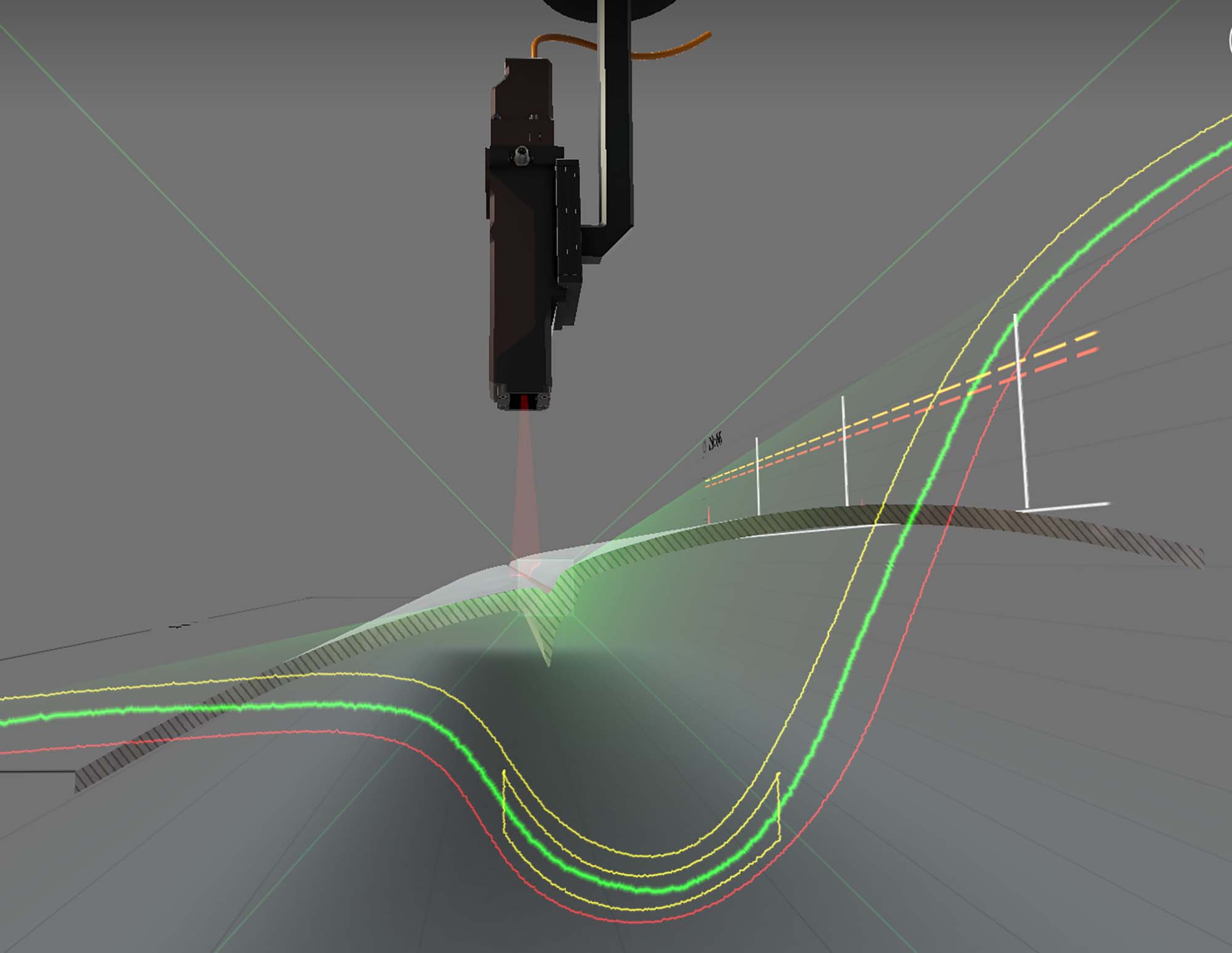

PLASMO: Due to the fact that our products ever since their invention are not depending on persons, they can all run completely unsupervised, which is perfect for the recent situation. We took during the quiet month our time to improve our products even faster than planned. We already started last year to develop a new cutting-edge successor for our well-known process observer. It will take the in-process monitoring to a whole new level. It is an all-new software where we took all our learning from more than 20 years intense industry experience together with a lot customer feedback to create an extremely customizable modern monitoring system. We can’t tell more at the moment, but we promise it will be ground-breaking in the quality monitoring sector.

E.E: How will these products / solutions help them in the next period?

PLASMO: All our products help customers to optimize their production and improve the quality of their parts.

Especially the new process observer will enable the customer to monitor his quality even more reliable than it’s possible with state-of-the-art systems at the moment. It will be able reduce the pseudo failures seriously, even in harsh and complex situations, which will reduce the overall production costs by reducing the parts that are scrapped or at least have to be reviewed.

E.E: How did your employees react to the new working conditions?

PLASMO: At the beginning of the shutdown there were daily meetings about video tools. This enabled regular communication between colleagues and departments to be maintained. At the moment there is the possibility to choose flexibly whether to work in the home office or in the office. The departments coordinate among themselves so that the permitted number of employees per square meter is not exceeded. This goes down very well with all our employees.

The requirements regarding safe distances and regular disinfection of workplaces, laboratories, sanitary and kitchen areas are also being implemented very well.

These measures give the employees security and a sense of responsibility both on the part of the company and on the part of their colleagues, and everyone continues to work for our company with positive motivation.

E.E: What innovative products / solutions did you come up with to meet the situation?

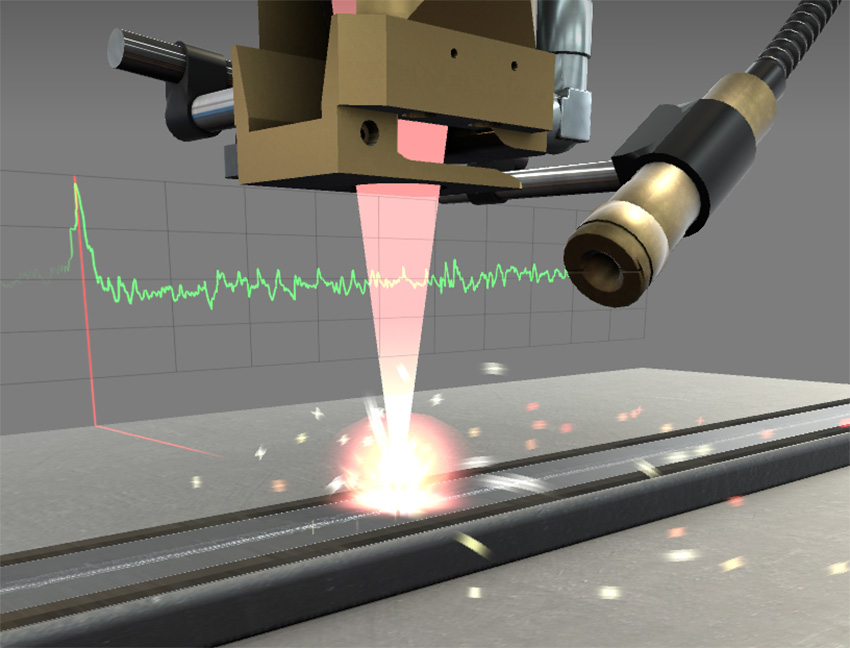

PLASMO: To accommodate the need of less persons in a certain space, our customers have to reduce the number of persons in their plants and factory buildings at a time. We support them to achieve this goal with our quality monitoring systems taking over inspection and controlling tasks to relieve the workers from these demanding tasks. Our industry proven products can be used to train specific limits and assessment criteria to fit perfectly to the required tasks for the customers job.

E.E: Under what conditions was the transition from the post-COVID-19 situation to the current one?

PLASMO: We think we are still in a post-COVID-19 situation but at least the travel restrictions in most areas have been lifted and the majority of our customers have opened the doors again. This means that we can visit customers again and carry out commissionings for our systems.

A positive experience during the covid 19 crisis was that most of our customers were able to switch from face-to-face meetings to remote meetings without any problems.

We hope that’s something we can keep. Instead of travelling for each meeting, sometimes over long distances, whenever it makes sense to do a remote meeting instead. This would at least make a small contribution to conserving resources and protecting the environment.

E.E: What are your estimates for the rest of the year?

PLASMO: Most of our customers have ended their short-time working period and our business is ramping up strongly again. We are now in a phase in which we have to do our best to make up for the many postponed projects. Therefore, we expect a very good rest of the year.

We used the COVID-19 crisis to push internal projects that are often difficult to implement in parallel with ongoing business. Additionally, we used the time to further develop our products. Therefore, we are quite certain that the fourth quarter will exceed the expectations we had before the crisis.