Plastic Ingenuity is one of the largest custom thermoformers in North America with seven strategic locations across the U.S. and Mexico. Nearly all their products are custom designed for a specific customer and application in the food, healthcare and consumer products (CPG) industries.

In 2022, the company celebrated their 50th anniversary. More than 850 employees support Plastic Ingenuity’s efforts to enhance quality and circularity throughout all aspects of the manufacturing process while accelerating customers’ speed to market.

Interview with Dan Kuehn, President & CEO of Plastic Ingenuity.

Easy Engineering: What are the main areas of activity of the company?

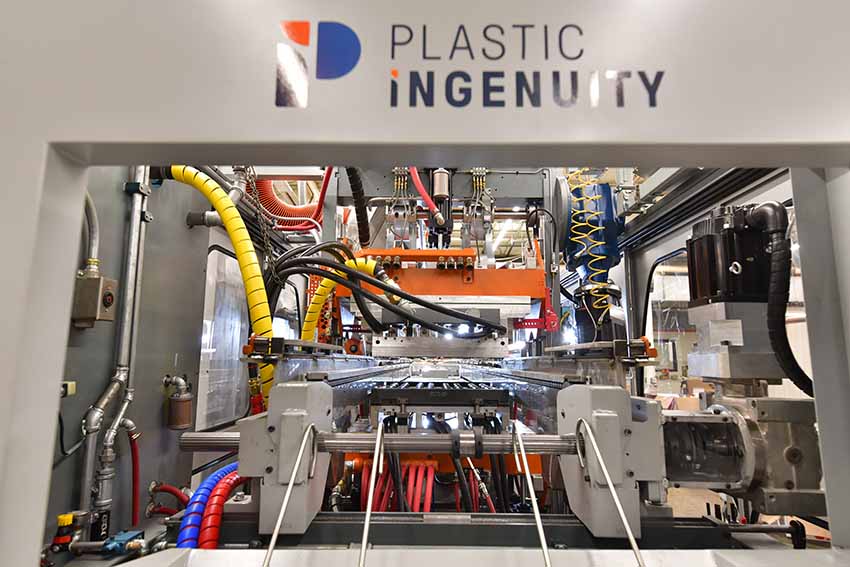

Dan Kuehn: Plastic Ingenuity is a vertically integrated custom thermoformer that builds our own tools, extrudes our own materials, and heavily customizes our own machines. Our technical sales and engineering experts are like an extension of the customer’s in-house team, providing direct support on the production floor, ensuring our parts run perfectly through their processes.

Furthermore, we are dedicated to helping our customers in the food, healthcare and CPG segments improve the circularity of their product packaging. Our services include sustainable packaging assessments, sustainability roadmaps, recyclability assessments, take-back programs and life cycle assessments.

E.E: What’s the news about new products?

D.K: Two of Plastic Ingenuity’s facilities are now International Sustainability and Carbon Certification (ISCC) PLUS compliant. ISCC PLUS certification enables the use of circular plastics from advanced recycling technologies that convert plastic waste from hard-to-recycle items into virgin-quality resin for use in new products. The ISCC PLUS system is based on the mass balance approach, which aims to seamlessly integrate advanced recycled technologies into existing production assets. This approach ensures credibility for tracing sustainably sourced materials throughout a complex value chain, from raw materials to finished products.

E.E: What are the ranges of products?

D.K: Plastic Ingenuity delivers end-to-end solutions and services to meet evolving market needs. We bring a client’s packaging vision to life, scale the product, and create a partnership that lasts beyond the product’s lifecycle. Our circularity experts work with high-volume customers in healthcare, food and CPG to custom design recyclable packages with a lower carbon footprint, supporting waste reduction and sustainability throughout the global supply chain.

E.E: At what stage is the market where you are currently active?

D.K: The scale and buying power of large retailers and group purchasing organizations, non-governmental organization (NGO) leadership, legislative policy, consumer demands and investor influence are elevating the priority of sustainability efforts. However, each of our customers is at a different point in their sustainability journey. While some are just starting to define their goals, others have established and publicized commitments that they are aspiring to meet.

We offer a range of services to support our customers, including sustainable packaging assessment, sustainability roadmaps, recyclability consulting, life-cycle assessment and take-back programs. We aim to inspire brands in the food, healthcare and CPG industries to adopt packaging that is as sustainable as possible without impeding its function, which is to preserve and protect its contents.

E.E: What can you tell us about market trends?

D.K: Corporate responsibility and accountability are key drivers in the transition to a more circular economy. In our 2022 Packaging Sustainability Stakeholder Study, professionals at retail, healthcare and CPG organizations were candid about their business priorities and sustainability goals. For example, 64% of respondents said their organizations are focused on maximizing post-consumer recycled (PCR) content in their packaging to enhance circularity. Advanced recycling techniques and mass balance systems have the potential to unlock new opportunities for using PCR materials in more types of packaging, including healthcare applications that are more highly regulated. Additionally, design optimization helps determine where packaging reductions can be made. A minimalist approach can help reduce weight and material usage, increasing shipping and other downstream efficiencies.

E.E: What are the most innovative products marketed?

D.K: We’re proud of our work with Merit Medical Systems to develop a packaging solution that would eliminate shipping damage, decrease material waste, and reduce packaging costs. This redesign achieved a 133% increase in devices per pallet, a 57% reduction in transatlantic freight costs, and a 52% reduction in packaging material costs. Critically, the packaging helps prevent device damage while being robust enough for reuse. This is essential for patient safety.

Another excellent case study is from the food industry. Creminelli Fine Meats sought to enhance the sustainability of their ready-to-eat charcuterie tray while also reducing food loss. We first conducted a sustainability assessment focused on material efficiency, structure selection, and design for recovery. Then we developed a sustainability improvement road map to determine Creminelli’s priorities and choose a path forward. Together we selected 80% PCR for the redesigned tray, which is the equivalent of 11.3 million recycled water bottles used annually. The new packaging also reduced material usage by 7% and minimized inherent greenhouse gas emissions.

E.E: What estimations do you have for 2023?

D.K: We believe there are many reasons to be optimistic about the future of circularity and plastic recycling. A renewed focus on sustainability has invigorated the industry. Through strategic actions and collaboration with brand owners and others in the value chain, key stakeholders are activated to make lasting change. The 2020s may be known as the decade when plastic recycling took the next leap forward. We’re excited to continue contributing to new technologies that will help unlock the full potential of plastics recycling.