PRAGMA designs, manufactures and distributes portable instruments and integrated systems for nondestructive testing (NDT) of materials. NDT is about inspecting parts being manufactured or in-service. They do portable systems for practicality on the field and we also do fully automated systems with robots.

The company’s products are very powerful, simple to use, handling multiple modalities and multiple platforms. NDT is a pragmatic world with real applications and problems and therefore it requires pragmatic solutions.

Interview with François Mainguy, CEO of PRAGMA.

Easy Engineering: What are the main areas of activity of the company?

François Mainguy: Our manual and automated solutions are used to inspect a wide range of metal and composite parts, to check for material properties and flaws in industries like aerospace, automotive, wind, oil and gas and nuclear energy.

The inspections we do use nondestructive testing technologies and also metrology technologies.

E.E: What’s the news about new products?

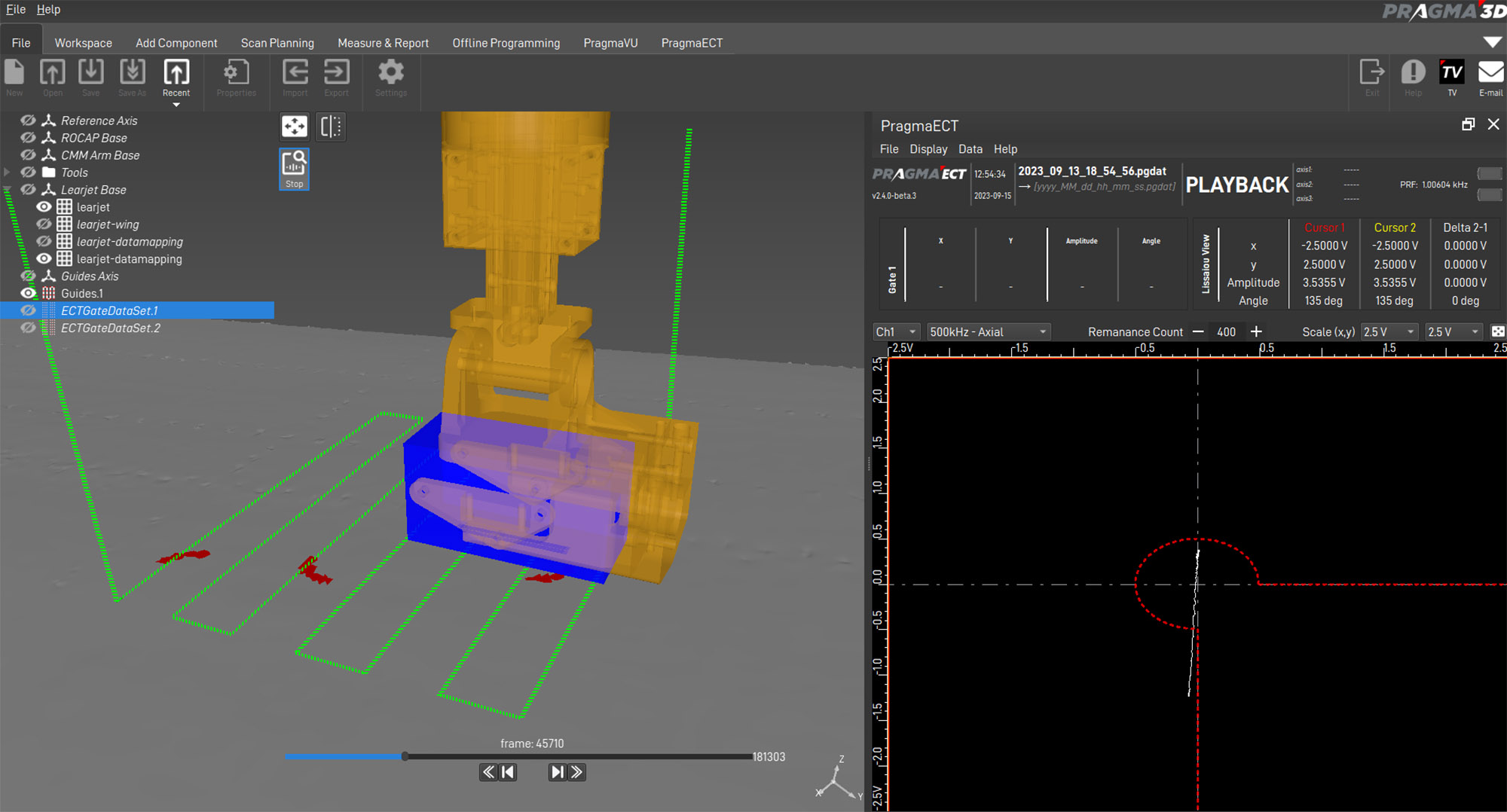

F.M: For several years, we have been working on the development of Pragma3D, which is an innovative new software application that is intended to realize the goals of the NDE 4.0 motivation that we see in the market.

Pragma3D is the result of more than 25 years of experience in NDT. It creates a pathway to become the “SolidWorks® of NDT”, combining the ease of use of a modern CAD software GUI with advanced 3D features. The goal is to empower the entire NDT community, from NDT trainees to the most experienced Level IIIs.

Pragma3D makes data fusion a reality accessible to everyone, and spearheads the convergence of NDT with metrology, thanks to PRAGMA’s strategic partnership with Hexagon®.

In conjunction with that, and to allow PRAGMA 3D to be deployed more easily on the field in a portable way, we are very enthusiastic about the release of our new PragmaFlex instrument platform, to which we can attach several nondestructive testing modalities, such as ultrasound, eddy current, bond testing and the likes.

The PragmaFlex platform marks a milestone in nondestructive testing history as it is the first ever instrument designed with NDE 4.0 principles in mind. Aiming at the integration of tools, test methods and digital technologies, this sets the stage for new breakthroughs in nondestructive testing. With a powerful CPU, wide diversity of peripherals and Windows IoT operating system, it has all the horsepower to accommodate the most challenging applications.

E.E: What are the ranges of products?

F.M: PRAGMA designs, engineers and produce a wide diversity of products. It ranges from hardware instruments and accessories, like probes, wedges, all the way to software products. We also supply a number of well-known suppliers with OEM components.

E.E: At what stage is the market where you are currently active?

F.M: The market of nondestructive testing has been in constant evolution and development since the 1940’s. The current state of the market is that new technologies are being embraced but still are lagging when compared to markets like metrology and other manufacturing technologies. But thanks to software like Pragma3D, instrument like the PragmaFlex and a few active players in the market, nondestructive testing is catching up quickly.

E.E: What can you tell us about market trends?

F.M: Historically, and still as of today, the operations in nondestructive testing has always been in silo operations. Be it a department of quality assurance and manufacturing, be it very specific services that are being called on demand to respect the requirement by the customer or the law. The silo operation mode has been relatively ok to allow the businesses to operate up to the early 2010. But it became very clear that the lack of software capability to exchange the information with fluidity, with the customers and with the other departments, made it such that the market is affected by this silo operation. PRAGMA has a strong resolve and business motivation to break those barriers to make sure that the digital workflow of companies is not affected by NDT anymore, and is walking the talk by developing an impressive suite of software and hardware products such as the PragmaFlex and Pragma3D.

E.E: What estimations do you have for the rest of 2023?

F.M: PRAGMA is currently consolidating its technological advance with Pragma3D, and is currently revving up to consolidate its current technology advances in aerospace, automotive and wind. PRAGMA is also preparing the grounds for a more active presence in oil and gas starting in 2024.