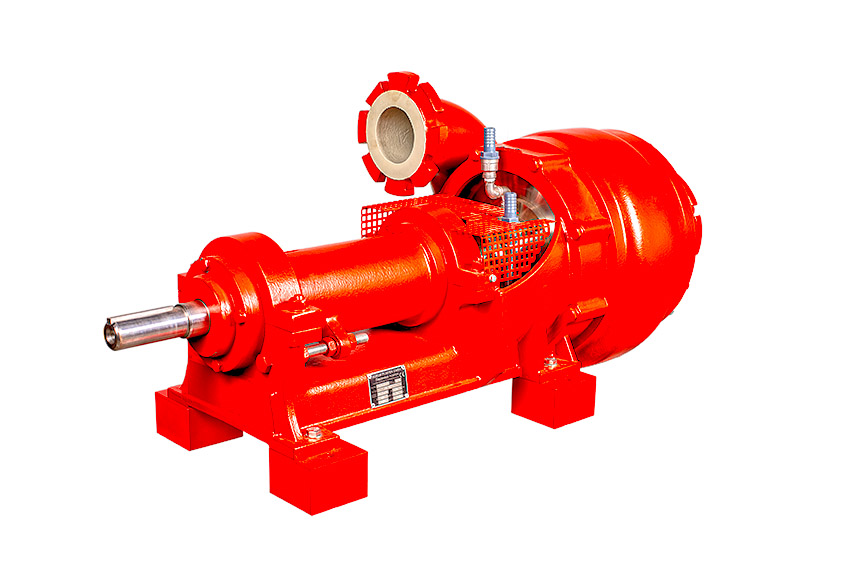

Habermann Aurum Pumpen GmbH is one of the leading manufacturers of centrifugal pumps, ideal for processing slurries. Their product portfolio includes primarily slurry pumps manufactured to “Habermann specifications” like e.g., the highly wear resistant HPK and NPK pump series, the submersible pumps Challenger & Heracles, as well as the dredging pumps for tunnel construction and special civil engineering. The company’s pumps are integrated into a wide variety of industries, such as mining and mineral processing, energy industry, metallurgy, chemical and pigment industries. They also set new standards with their materials such as the innovative polyurethane APFlex or CeramCarbide coating. Besides pumps, Habermann Aurum Pumpen also offers valves and fittings as well as engineering services.

Interview with Stefan Leuchtenberger, Management in technology, production, and service at Habermann Aurum Pumpen GmbH.

Easy Engineering: What was the research behind the products/solutions design?

Stefan Leuchtenberger: The focus is on finding individual solutions in each individual case. This requires a close and regular exchange with our clients, which is crucial for us.

E.E: Which are the key aspects of the process of product/solution development?

S.L: The most important aspects to find a product solution would particularly be the individual Know-How of the various pumping media, as well as the corresponding configuration of each pump.

E.E: How quickly do you adapt your products/solutions to different requirements?

S.L: We can flexibly adapt our pumps to different requirements of our clients: Customizing the manufacturing process of the pumps, allows us to meet specific needs of our clients.

E.E: What are the most common requirements from clients?

S.L: The most frequent requirements of our clients include transportation and delivery of highly abrasive media or applications in the field of chamber filter press and cyclone feeding.

In regard to suspensions, our clients often request to separate liquids and solids.

E.E: How do your products/solutions solve problems that your clients may have?

S.L: A regular information exchange with the customer plays a major role in our corporate culture. That is important for us because we like to advise our customers in the best possible way. As we offer pump solutions tailored to our clients, we can directly meet the requirements of our customers and can solve possible problems and offer optimal pumping solutions.

E.E: Tell us about products/solutions innovation.

S.L: We are currently working on many innovations in material and seal technology to make the pumps more efficient and wear-resistant. As mentioned above, we have developed various materials as APFlex or CeramCarbide which make the pumps even more durable and constant towards abrasive and corrosive media.

E.E: What are the trends in product/solution design in your area of activity?

S.L: The worldwide discussion on the reduction of greenhouse gases has also been an important theme in the “pump scene” for a long time – because also in this area, topics like sustainability and conservation of resources are increasingly gaining attention. We have focussed on subjects like the conversation of resources and durability in recent past. Besides, we are dealing intensively with efficiency of our pumps to improve them even further. Thanks to our close contact with our customers, we ensure, that our pumps are designed for the needed operation point and deliver the best level of efficiency. The latter is a further major challenge, especially by the mining of suspension. Additionally, we offer high efficiency by offering our clients the possibility to drive the pumps with a frequency converter.

E.E: What are your estimations for the rest of the year?

S.L: The corona-pandemic also caused disturbance in the engineering industry and the companies of this sector. Nevertheless, we successfully managed to overcome this difficult situation. We have considered it a challenge, adjusted ourselves accordingly and have managed to break new ground. In this period, we optimized internal processes. We implemented the quality management system ISO 9001 as well as SCC (Safety Certificate Contractors) system, that guarantees safety, health, and environment protection. In addition, the Water Resources Act was implemented as well. Equally, we also optimised many things in technical areas of our work. Therefore, we are positive about the future and the remaining months of 2021. I am positive, that we can bring our enhanced know-how even more goal oriented to the market. This is how the service and communication culture of our company continues and how it will be of great use for our clients. Hence, not only we will plan agile, reliable, we will also keep an open and regular contact with our clients.

Personal details:

Stefan Leuchtenberger is a certified industrial mechanic and mechanical engineer. Since 1988, he has been occupied with “Pumps in the chemical”, initially as a fitter in the pump repair shop Sachtleben Chemie GmbH, Duisburg. Then from 1991, he was the long-time director of the pump office at Sachtleben. He oversaw approx. 3000 pumps of widely differing sizes and types and was responsible for maintenance and replanning. Since 2005 he worked as technical support and was also responsible for maintenance and reparation of the entire machinery. From 2010 to 2019, Stefan Leuchtenberger worked as an authorised officer and technical director at a pumps maintenance in Oberhausen. Since 2019 he is working in the management of Habermann Aurum Pumpen GmbH in the field of technology, production, and service. He conveys his years of experience in the company and is active also in other fields.

Website: https://www.habermann-aurum-pumpen.de/en

YouTube: https://www.youtube.com/watch?v=bqb_z5KbZMI&ab_channel=HabermannAurumPumpenGmbH

Habermann Aurum Pumpen GmbH:

Harpener Heide 14

44805 Bochum

Tel.: 0234 8935700

E-Mail: info@aurumpumpen.de