Not all conveyor belts are created equal. In this special feature, Leslie David explains the criteria used to assess the properties and characteristics of single and multi-ply rubber conveyor belts and the influence each part of the criteria has on whether or not a belt will be fit for its intended purpose.

A complicated subject

Industrial conveyor belts appear to be very simple structures to the casual observer. In very basic terms, they are simply thick bands of black rubber that run around metal conveyor frames. They transport a multitude of different materials thereby performing a hugely important role in industries around the world. In reality however, conveyor belts are technically very complex. Literally billions are spent every year buying, fitting and running them but much can go wrong (and often does!) when a belt is not up to the task it was chosen to perform. However, you do not need to be a conveyor belt expert to make an informed selection as long as you make good use of the information available to you.

The technical datasheet

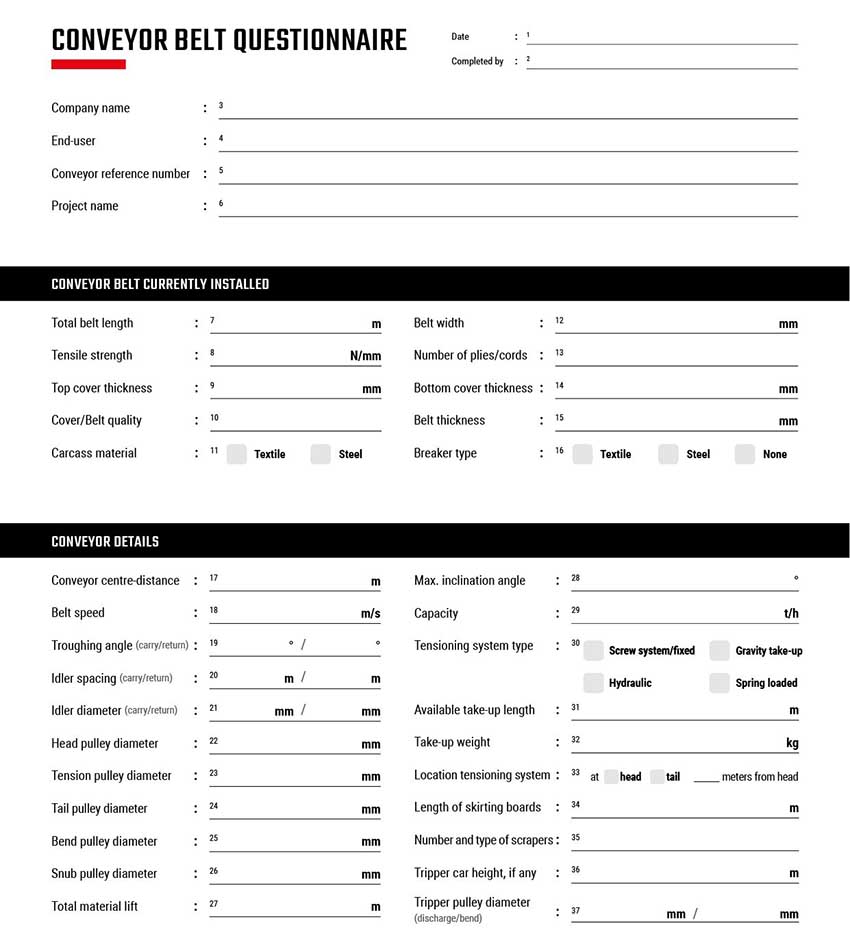

Selecting a conveyor belt involves making a complicated assessment of all available parameters including the conveyor system itself, the materials being conveyed, the working conditions and health & safety. For new conveyor installations the first stage of any belt selection should involve the use of a belt calculation program overseen by a professional conveyor belt engineer. It can also be a good idea to follow the same process when a conveyor is proving to be problematic. It is important to be absolutely sure that the actual specification of the belt is correct in the first place.

Good belt selection involves making an assessment based on quite a wide-ranging criteria. To be honest, for many people who work with conveyors, much of the criteria is meaningless to them although they would understandably be reluctant to admit it. All responsible manufacturers, service companies and traders should, as a matter of course, automatically provide a technical datasheet (TDS) for the specific version of the belt that they are proposing to supply because this where much of the selection criteria should be found. The TDS should be supported by the manufacturer’s product documentation (product specific datasheet) because this should contain important additional information such as recommended minimum and maximum pulley diameters and maximum useable widths.

My best advice is to always insist on seeing a technical datasheet and a product datasheet before you place an order. Even the design and clarity of the documents can be a good indicator as to the professionalism of the supplier you are dealing with. It is also wise to request a certificate of (manufacturers) origin so that you know the true provenance of the belt in the event of a problem.

Test methods and test standards are not the same

Alongside each part of the criteria on the technical datasheet should be details of any applicable test methods and international standards such as ISO or DIN for example. When assessing quality credentials it is essential to differentiate between what is simply an approved method of conducting a particular test (the test method standard itself) and the actual quality or performance standards attained during that test. In itself, the fact that a belt has been tested according to a certain method actually means very little. What is important is the actual level of performance achieved during the testing compared against the minimum acceptable level of performance dictated by the test standard. In other words, was the performance standard achieved?

Unfortunately, unless specifically stated otherwise, technical datasheets provided by manufacturers and traders almost invariably only show generic information such as the minimum standard demanded by a specific test. Some do show a few ‘actuals’ but it is extremely limited. The data therefore does NOT reflect the actual performance achieved during the test or even a level of performance that the buyer might reasonably expect. This even applies to the dimensional measurements and acceptable tolerances such as the thickness of the top and bottom covers. Apart from Dunlop in The Netherlands, who show actuals on their technical datasheets on most applicable values, this shortcoming applies to all suppliers.

The vast majority of conveyor belts in use today are either single ply or, most typically, multi-ply. For the benefit of the uninitiated, their construction consists of two elements – a fabric ply carcass, most commonly Polyester warp and Polyamide (nylon) weft (EP) fabrics, with a thin layer of rubber in between the plies (skim rubber or inter-ply rubber). This structure is covered by an outer layer of rubber on both sides referred to as ‘the covers’. Technical datasheets are therefore based on these two fundamental elements. Each element has its own criteria for testing methods and performance standards. On most technical datasheets, data relating to the carcass is usually shown first.

The carcass

The carcass provides the innate strength of any conveyor belt. It not only has to bear the loads placed upon it but also repeatedly flex around the drums and pulleys of the conveyor structure. The internal structure of the belt carcass dictates the tensile strength of the belt. Because of its fundamental importance, the tensile strength is usually the first piece of data shown.

Selection criteria – Tensile strength at break (N/mm)

Virtually all industrial conveyor belts are defined by their tensile strength. The carcass absorbs the force when tension is applied to the belt. The greater the required tensile force to move the transported material, the greater level of strength demanded of the belt carcass. Importantly, the strength under load needs to be consistent throughout the belt both longitudinally and transversely in order for the belt to steer and handle correctly. The tensile strength of a belt is measured according to the ISO 283 test method. Quite simply, this involves pulling a section of belt apart and measuring the force that it will endure before it breaks.

As I touched on earlier, a typical technical datasheet will simply state the minimum tensile strength that the manufacturer/supplier is claiming the belt will achieve. A poor quality belt will often be borderline and, due to inconsistencies in the production process and the quality of the fabric plies used, sometimes below the required minimum strength. When competing on price, manufacturers will habitually keep every aspect of the construction cost to an absolute minimum. The better quality conveyor belts will have a safety margin included, ideally as much as 10% or more.

Selection criteria – Carcass Tear Strength (N)

Depending on the working environment and the kind of materials being conveyed, the overall tear strength of a conveyor belt can be hugely important. For clarity of meaning, a ‘tear’ is best defined as what happens when a piece of material (a section of carcass or rubber cover) is pulled apart in opposing directions. Although there is a defined method of testing (ISO 505: 2017) there are no standardised performance requirements.

The test consists of mounting two cut ends of a test piece of belting or rubber cover in the jaws of a tensile testing machine. An initial tear is made in the test piece, which is then pulled apart in opposing directions. The force necessary to propagate the tear is then measured. Examination and analysis of the multi-peak tear resistance test traces is conducted in accordance with ISO 6133.

Selection criteria – Adhesion between the plies

The strength of adhesion (bond) between the various layers of plies and between the plies and the covers is also a standard part of the assessment criteria. The adhesion (measured according to the ISO 252 test method) literally involves pulling the layers apart and measuring the force required in Newtons per millimeter.

When it comes to adhesion, manufacturers need to strike a balance because there should obviously between a strong bond between all of the layers so that the belt stays intact under load and while being subjected to repeated flexing. However, if the adhesion level is too high then this can create problems when trying to make a spliced connection joint because a section of the rubber skim needs to be removed.

Selection criteria – Thickness

The measurement method for carcass thickness is ISO 583. The actual thickness of the carcass largely determines the suitable usage range for the belt. A very thin carcass will require less material to manufacture and be cheaper in cost. It will typically be easy to flex around pulleys and be able to take a troughed shape in narrow width conveyor frames. However, being thin and flexible also makes the belt more sensitive to damage from material impact and sharp edges. The thickness of a carcass can be increased simply by increasing the amount of rubber between the fabric plies and/or the number of plies. The downside to this is that the belt will become more rigid and could prove to be problematic and actually lead to internal damage within the carcass.

With larger width belts and bulky, heavy material dropping on the belt from height, the extra rigidity created by increasing the thickness will provide added resistance to these elements. In reality, quality manufacturers try to match the most commonly expected usage of a belt type to the carcass design for each specific belt type and strength. In other words, making the carcass thick and rugged enough but without limiting the application area by being too thick or too thin.

Selection criteria – Elongation

The elastic elongation (stretch properties) of a carcass are more important than many people may realise. Using test method ISO 283, the amount of elongation is measured while the test piece is under a tension that is the equivalent of 10% of the stated tensile strength. Again, a balance has to be achieved because the belt needs to be able to accommodate geometric changes such as pulleys and transitions. On multi-ply belts, insufficient elongation can lead to shear stresses, which in turn can cause delamination (separation) issues. However, too much elongation would result in insufficient tension in the belt.

Generally speaking, the maximum elongation (at maximum operational tension, being 10% of the nominal belt breaking strength) for multi-ply belts would be 1.5% for lower tensile belts, max. 2.5% for the mid-range and 3% for the really high tension belts. Personally, I would not expect to see much more than 1% in the lower range and 2% in the high tension classes. Anything appreciably less than that would mean that the belt is more sensitive to dynamic failure and more prone to damage.

Resisting damage

Crucially, the carcass and the fabrics that are used within it play a very important role in handling (dissipating) the impact of objects falling on to the belt and also resisting the propogation of tearing and ripping when objects become trapped and penetrate the outer covers. This is a key reason why Polyester warp and Polyamide weft (EP) fabrics are most commonly used. Although not part of the criteria used within a technical datasheet, the type of fabric used will be stated on the document as part of the belt designation. For example, EP 400/3 4+2.

Worringly, laboratory testing is revealing that more and more belts, including many that are being manufactured in Europe, are being declared as having an EP (polyester/nylon mix fabric) construction when they actually have entirely polyester (EE) fabric plies. A simple one-on-one replacement of the Nylon with Polyester is not possible due to the lower elasticity of Polyester because it would lead to a very rigid carcass with a significant reduction in troughability. A belt that will not seat properly often results in misalignment of the belt relative to the conveyor structure. Therefore, a much lower amount of polyester weft material is used in the exchange. A direct consequence of less material of lower elasticity is that impact resistance and rip resistance are markedly reduced, making the belt even more vulnerable to damage than usual.

The objective of using purely polyester fabric is to minimise costs because polyester costs some 30% less than nylon. Although a highly tempting price may provide a clue, the deception cannot be detected without laboratory testing so the manufacturers are confident that their dishonesty is very unlikely to be exposed.

The covers

In the majority of cases, the quality of the outer covers have the greatest influence on the performance and operational lifetime of a conveyor belt. This most certainly applies in the case of belts that need to be able to resist the ravages of heavy, sharp, abrasive materials, high material temperatures or where the conveyed product contains oil of any kind, such as grain for example. Within this, the ability of the rubber covers to resist abrasive wear will have a very significant bearing on the wear life of the belt. The destruction of the covers will allow the carcass materials to be exposed, which will then gradually deteriorate and lose integrity and strength. This will eventually lead to rupture of the belt and costly downtime and spillage.

Selection criteria – Abrasion resistance [mm³]

The two most commonly referenced standards for fabric reinforced belting are the international ISO 14890 (with abrasion resistant classes H, D and L) and German DIN 22102 (with abrasion resistant classes Y, W and X). In Europe the longer-established DIN 22102 standard is still very often used, although the most current version of this standard references the ISO 14890 on most topics, making both more or less identical. Generally speaking, the DIN grade “Y” (or ISO 14890 closest equivalent grade “L”) relates to ‘normal’ service conditions and DIN grade “W” (close to ISO 14890 grade “D”) for particularly high levels of abrasive wear. DIN grade “X” (close to ISO 14890 grade “H”) is regarded as the most versatile because in addition to resisting abrasive wear it also has good resistance to cutting, impact (from high drop heights) and gouging, usually caused by heavy, sharp materials. To achieve these characteristics the rubber compound contains a higher than usual element of natural rubber (NR) and is therefore usually the highest priced option.

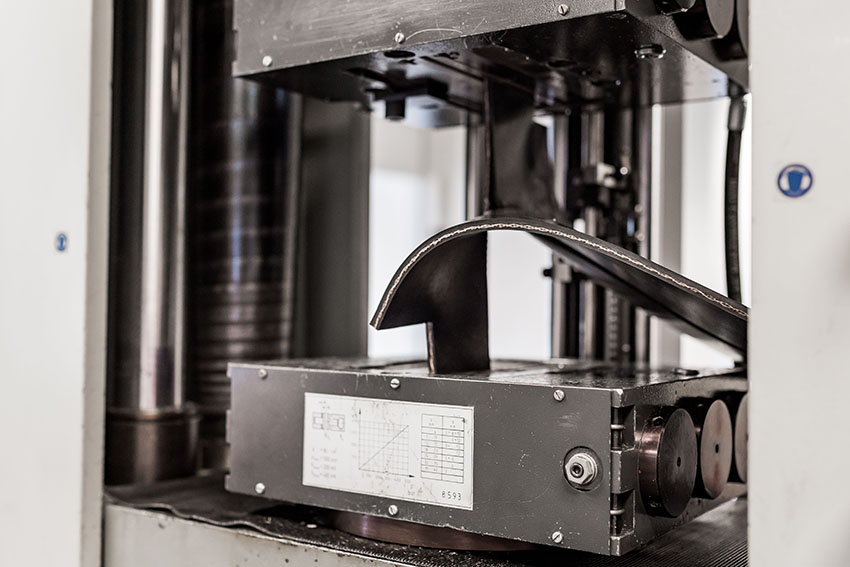

The method used to measure abrasion resistance (ISO 4649 / DIN 53516) involves moving a test piece of the rubber across the surface of an abrasive sheet mounted on a revolving drum and is expressed as volume loss in cubic millimeters, for instance 150 mm³.

The key factor to bear in mind when looking at abrasion test results is that higher figures represent a greater loss of surface rubber, which means that the higher the figure the lower the resistance to abrasion. Conversely, the lower the figure the better the wear resistance.

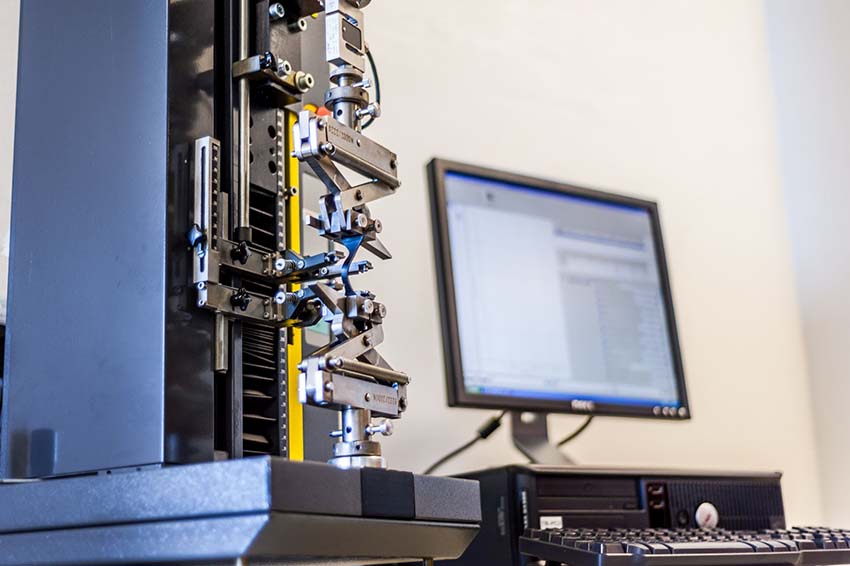

Selection criteria – Tensile strength at break (MPa)

The tensile strength of belt covers is measured according to the ISO 37 test method and is typically expressed as amount of force in megapascals (typical range of 15-30 MPa). During this test, the material is stretched up to the point of failure. This point of rupture (referred to as ‘the ultimate tensile strength’) indicates how much force or stress the rubber can withstand before breaking and has considerable influence on the overall tensile strength of the belt. As I mentioned earlier, technical datasheets provided by manufacturers almost invariably only show the minimum standard demanded by a specific test or, in many cases, simply the test method reference number and nothing more. This therefore does not reflect the level of performance that you might reasonably expect.

Selection criteria – Elongation at break (%)

The elongation at break is the extent a rubber material can be strained (%) before it breaks. Using ISO test method 37, tensile force is exerted in order to stretch the rubber to breaking point. The elongation at break is expressed as a percentage percentage of the original length of the test piece.

As with the tensile strength, the elongation of the covers also has an important bearing on the elastic elongation properties of the belt as a whole. This means that even if the carcass has good mechanical properties, if the quality of the rubber covers is poor then this will have a seriously detrimental effect on overall performance, handling and the ability of the belt to withstand physical punishment (such as heavy, sharp material falling from height) and rip and tear propagation. Typically, some 70% of a conveyor belt is made up of rubber so despite its critical role, it is usually the primary target for cutting corners.

Selection criteria – Tear strength [N] / [MPa]

Testing the tear strength of the rubber covers is similar to the testing of tensile strength. The difference is that a specifically designed and pre-damaged sample is pulled until it breaks. The damage acts as an initiation to a further tear and inevitable break of the sample. The sample will typically break at a lower tension than the undamaged sample.

In real life, the covers of a conveyor belt will be damaged by material impact. When the tear strength is low, these small areas of damage become larger areas of damage as a result of the strain placed on the covers by continuous flexing around pulleys and drums. However, rubber covers with a high level of tear strength will contain the damage much more effectively, thereby achieving a longer operational life. Although international standards only focus on the ultimate tensile strength, evaluating the tear strength in combination with the expected operational conditions of the belt is a worthwhile exercise. Belts conveying large and sharp materials greatly benefit from a cover rubber that has both good tensile strength and high tear strength.

Selection criteria – Hardness (Shore]

The hardness of rubber covers is usually measured by the depth of indentation caused by a rigid ball under a spring load or dead load (ISO 7619). The spring-loaded meter gives Shore A values of hardness ranging from 0 to 100. For the majority of rubber cover grades a hardness of between 60 to 65 Shore is the expected norm.

As with the degree of elasticity (elongation), there is a relatively fine balance that needs to be achieved by the manufacturer because anything outside of this range can make the covers prone to damage. Although soft rubber covers may provide better damping on impact, the greater amount of deformation will still make it subject to damage. Conversely, a hard cover may eventually lack the ability to allow bigger deformations because over the course of time, all rubber materials become harder and lose flexibility as a result of ageing. This natural ageing process is accelerated when belts are subjected to heat or chemicals.

Selection criteria – Ozone & ultra violet light resistance (EN ISO 1431/1 procedure B)

Despite its crucial importance in terms of operational lifetime, resistance to the damaging effects of ozone and UV is rarely ever mentioned by traders or manufacturers in their product documentation. This is almost certainly because the anti-ozonants that need to be used during the mixing process of the rubber compounds are relatively costly. Ozone becomes a pollutant at ground/sea level and exposure is unavoidable. It increases the acidity of carbon black surfaces and causes reactions to take place within the molecular structure of the rubber resulting in surface cracking and a marked decrease in its tensile strength.

Likewise, ultraviolet light from sunlight and artificial (fluorescent) lighting also accelerates deterioration because it produces photochemical reactions that promote the oxidation of the surface of the rubber resulting in a loss in mechanical strength. In both cases, this kind of degradation causes the covers of the belt to wear out even faster than they should. My advice is to always make ozone & UV resistance a required part of the specification when selecting any rubber conveyor belt.

Blind acceptance

Because of the everyday demands of working life and, indeed, budgetary pressures, it is very easy to fall into the trap of simply accepting that the specification promised by the belt supplier will be what you actually receive on site. The same applies to the level of performance and quality standards claimed by the supplier. As I explained earlier, just because there is a test method or quality standard reference shown alongside a particular characteristic it does not necessarily mean that the belt supplied will actually meet that standard.

This may sound very cynical but blind acceptance can prove to be extremely expensive. Naturally, there should be an element of trust in any transaction. However, it is important to consider the growing evidence of misleading information right through to outright deception in the conveyor belt industry.

Taking the time to study the technical datasheet (TDS) for the specific belt you are being offered, together with the manufacturer’s product specification datasheet before you place your order will certainly be time well spent.

Acknowledgments: Conveyor belt selection is a massive topic involving a complicated assessment of all available parameters relating to the actual conveyor system, materials being conveyed and numerous belt specification options. Although I have tried to ‘keep to the basics’, it has nonetheless been a challenging task. I am therefore deeply indebted to Rob van Oijen, manager of application engineering for Dunlop Conveyor Belting in The Netherlands, for his invaluable technical and professionally impartial assistance in the compilation of this article.

About the author

Leslie David

After spending 23 years in logistics management, Leslie David has specialized in conveyor belting for over 15 years. During that time, he has become one of the most published authors on conveyor belt technology in the world.