Ramén Valves was established in 1945. The company serves a wide range of industries and applications with tailor made valve solutions. They are located a few kilometers northwest of Stockholm, Sweden, where have the sales office, workshop and warehouse. Over the years, Ramén Valves has built up and maintained their reputation for reliability, excellence and innovation, while consciously working with our extensive global distribution network to help customers all over the world.

Ramén’s deliveries to the Americas, Asia, Europe, Australia, and Africa are strong proof of how well they support customers, wherever they may be.

Interview with: Stéphane Blanchet – Sales Manager & Per Wennersten – Managing Director.

Easy Engineering: Which are the most futuristic products / solutions from your portfolio?

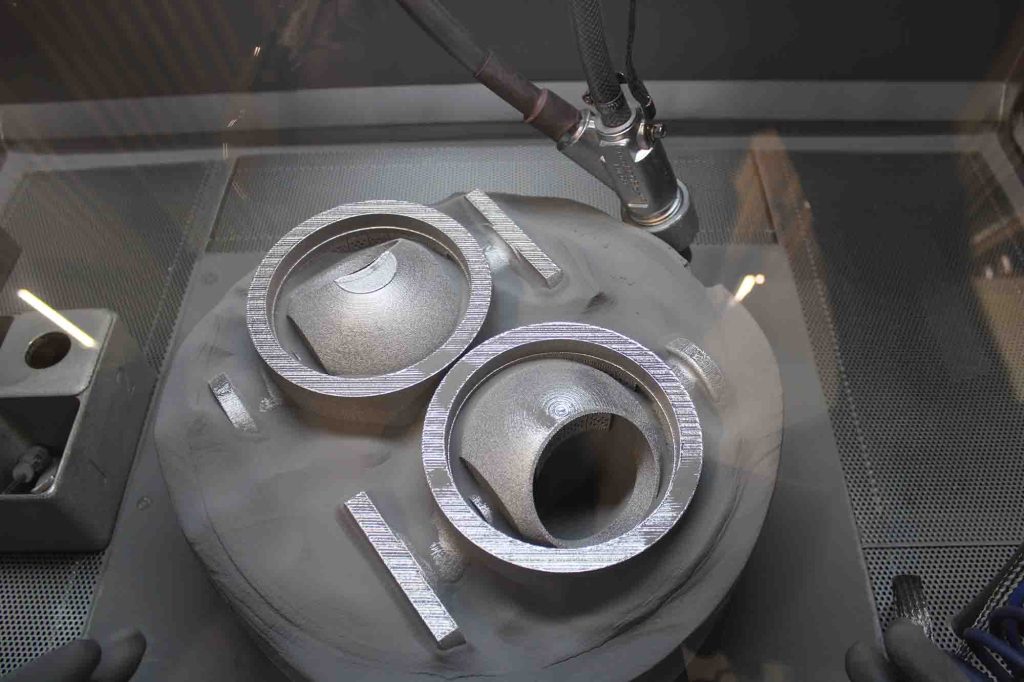

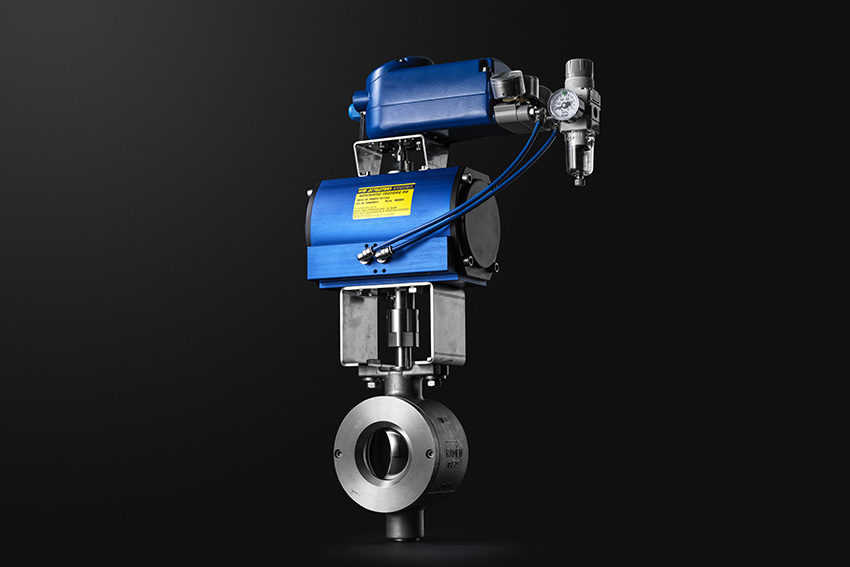

Stéphane Blanchet & Per Wennersten: Our portfolio is a testament to cutting-edge innovation and a forward-thinking approach to valve technology. Among our state-of-the-art products, we proudly feature control valves constructed with titanium grade 5, fabricated through the process of additive manufacturing (AM). This method allows us not only to reduce lead times but also to foster environmental sustainability through efficient material usage, and to implement rapid design changes that are tailored to customer needs.

Furthermore, our commitment to a sustainable future is manifested in our conscious decision to phase out the use of hard chroming in our manufacturing processes. In its place, we have embraced the SuperExpanite® treatment – an eco-friendly, gas-based alternative that generates no toxic waste and is recognized for having the industry’s lowest carbon footprint.

Hard chromed coatings typically have a hardness of HV 900-1,000, while SuperExpanite® achieves HV 1,200±100. The increased hardness of Ramén Valves’ products treated with SuperExpanite® will therefore give the products a better wear resistance, making them ideal for applications involving abrasive materials.

These featured products showcase Ramén Valves’ firm commitment to excellence and innovation, setting new standards in the industry and placing us at the cutting edge of modern valve manufacturing.

E.E: Tell us about the company’s long-term goals / prospects?

S.B & P.W: Ramén Valves is committed to a future that not only elevates our presence in the valve manufacturing industry but also sets a standard for innovation, sustainability, and global reach. Our long-term goals include:

- Creating state-of-the-art valve technologies and solutions through research and development.

- Implementing greener manufacturing processes, reducing waste, and creating environmentally friendly products.

- Exploring new markets and regions to strengthen our global position.

- Exploring opportunities to diversify into new business areas that align with our core competencies.

E.E: Tell us about product innovation and how does it impact the future?

S.B & P.W: Our exploration into cutting-edge technologies, such as 3D printing, has allowed us to create products that surpass conventional expectations. These innovations result in valves that are lighter in weight yet uncompromised in quality, more energy-efficient in operation, and competitively priced against traditional manufacturing methods.

We see product innovation not merely as a means to stay competitive but as a powerful tool to drive progress, sustainability, and meaningful change within our industry.

Through continuous research, development, and investment in new technologies, we aim to contribute to a greener, more sustainable future.

E.E: What’s moving your company forward?

S.B & P.W: We are dedicated to staying ahead of the competition and providing the highest quality solutions to our customers. Our commitment to innovation and sustainability has been the driving force of our success. Our passion for progress has allowed us to consistently meet the changing needs of our customers and remain at the forefront of the industry.

E.E: How do employees shape your company’s future?

S.B & P.W: At Ramén Valves, we firmly believe that our employees are not just a part of our company but the very heart and soul that drives our success and innovation. The knowledge and experience of our team play a crucial role in maintaining the quality of our products. From design to manufacturing to final inspection, our employees ensure that every valve meets the highest standards of performance and reliability.

E.E: How does the digital transformation affect your products / business?

S.B & P.W: The digital transformation has brought about a significant change in the way Ramén Valves runs its business operations, covering everything from marketing strategies and sales techniques to the very heart of our production processes.

For example, we’ve developed a specialized product platform, designed to provide all the relevant information our clients may need. This platform is accessible wherever and whenever our customers need it, granting them the flexibility to find answers and make decisions on their terms, regardless of location or time. In our pursuit to continually add value, we will soon be integrating a sizing tool powered by Conval® into this platform. This tool will allow our customers to directly size the valves they need based on their process data.

E.E: Tell us about research and development in your company.

S.B & P.W: Research and development (R&D) are not merely functions within our organization; they are the driving forces behind our commitment to excellence and innovation. Our pioneering efforts in R&D have positioned us as one of the world’s leading valve manufacturers to offer control valves constructed with titanium grade 5, leveraging the avant-garde technology of additive manufacturing (AM). This groundbreaking method not only facilitates shorter lead times but also represents a stride towards environmental sustainability and an accelerated design process.

Our dedication to advancing the industry doesn’t stop there. After many years of intensive research and meticulous exploration of alternatives to hard chroming, we’ve adopted the SuperExpanite® treatment. A gas-based process, this revolutionary treatment eliminates toxic waste and boasts the lowest carbon footprint in the industry. It reflects our unwavering commitment to ecological responsibility without compromising on quality or efficiency.

E.E: Tell us about the company’s future strategies and how will you adapt to the future.

S.B & P.W: Our vision for the future is firmly focused on adapting, innovating, and leading within the valve manufacturing industry.

Our commitment to improving both processes and manufacturing involves a strong focus on minimizing environmental impact. By actively supporting green technologies, we intend to align our practices with the global call for sustainable industrial solutions. In our effort to make manufacturing more environmentally friendly, we are advancing research into alternative materials and more efficient production methods.

The implementation of additive manufacturing techniques represents another area we are excited to explore. By making use of 3D printing and related technologies, we plan to create products that are not only more efficient but also customizable to a level previously unreachable.

E.E: How do you think the future will look like in your field of activity?

S.B & P.W: Looking ahead to the future of valve manufacturing, we see an exciting landscape filled with both opportunities and responsibilities. Trends like environmental considerations, alternative products, localized manufacturing, and digital transformation are likely to shape our field in the coming years. We are prepared to adapt to these changes and continue to lead in creativity, quality, and care for the environment.