Electricity is becoming more expensive, so energy efficiency is more important now than ever. Selecting the right drive for conveyors and transfer systems is therefore critical for taking sustainable, economical action. Highly efficient motors reduce energy costs.

Constantly increasing consumption of energy and resources has catastrophic consequences for the environment. Regulations and sustainability concepts therefore demand sparing use and conscious action. For the sake of the environment, CO2 emissions must be minimized, and energy costs reduced.

High efficiency classes reduce energy consumption

It’s precisely electric drives that are most affected by this topic, for they power the machines that are responsible for the lion’s share of total industrial electricity consumption. Regulations concerning the efficiency class of a drive should reduce energy consumption, for the higher the efficiency class of a drive, the less energy it consumes. Since July 1, 2021, in the 120 to 750W power range, according to the directive (EU) 2019/1781 for the execution of the eco design directive 2009/125/EC, therefore, only line-driven electric motors with an efficiency class of at least IE2 can be sold in Europe.

Regulations reduce consumption and costs

In the long term, this regulation has great added value for more than just the environment; the high efficiency classes also have a positive effect on annual energy costs. For example: A conveyor in three-shift operation is driven by a motor with a power rating of 250W. If the motor is in efficiency class IE5 instead of IE2, this will make an impact on the budget: The IE5 motor will save approximately EUR 200 in energy costs. If production makes use of numerous conveyors, energy-efficient motors will pay off even more – with regard to increasing energy costs in any case.

Long-term, sustainable, Montech

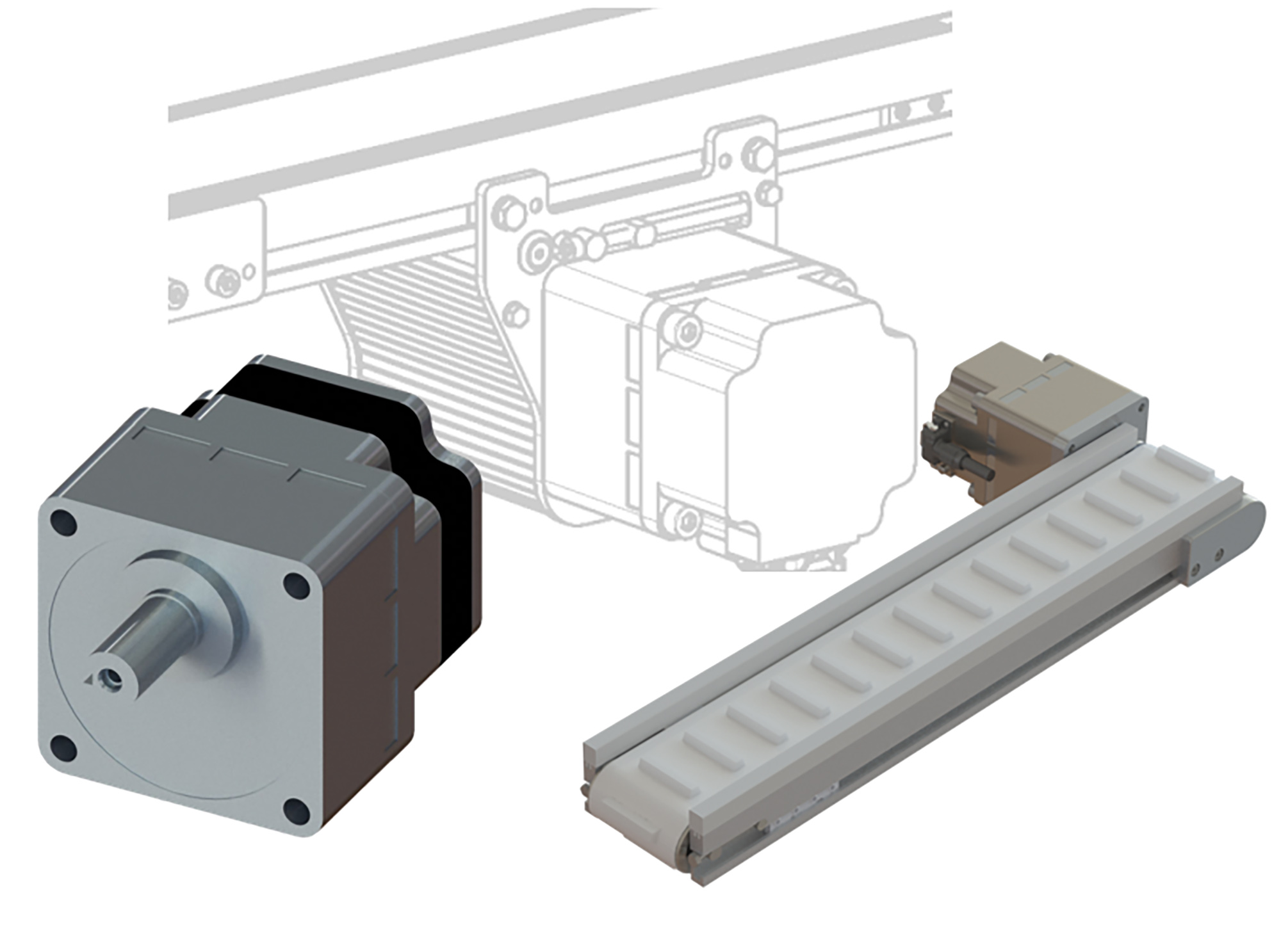

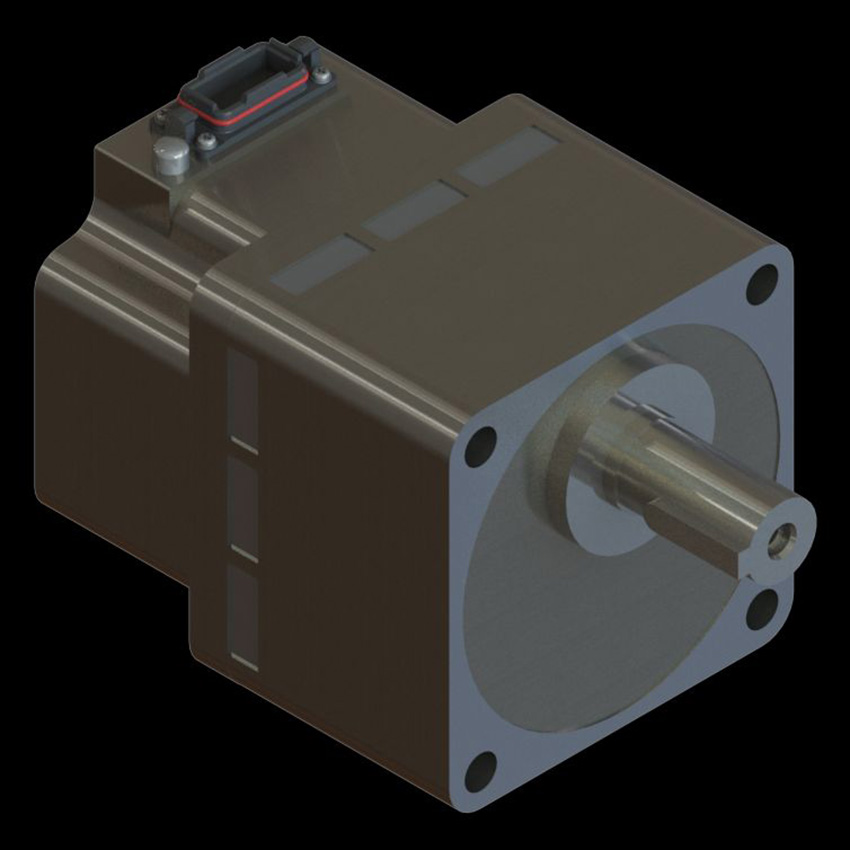

The Swiss technology company Montech specializes in the industrialization and standardization of state-of-the-art, unusual transport conveyors, transfer systems, and innovative aluminum framing systems for a broad and varied range of applications. The company strives for great energy efficiency and low energy costs by using electronically commutated motors for its conveyors and transfer systems. With regard to energy efficiency, these are up to 25% more efficient than line-driven electric motors with a minimum efficiency class of IE2. Even in comparison to the highest efficiency class IE5, the drives for Montech’s conveyors are up to 10% more efficient.

https://montech.com/ch/en/conveyors-roller-conveyor/