Interview with Mrs Marzena Szczotkowska-Topić, co-owner of RENEX Group

Easy Engineering: What new products / solutions do you have for your customers?

Marzena Szczotkowska-Topić: It is no secret that the COVID pandemic has surprised entrepreneurs around the world. As RENEX, we were fortunate to be able to draw upon the knowledge, experience and range of products and services from the entire scope of RENEX Group. For more than 30 years on the Central and Eastern European market, we have grown from a typical electronics distribution business to the present one – based on six broad areas of activity. In the time of the pandemic the key one turned out to be CLEANROOM. Within this framework, we build clean areas and provide equipment for them. For years we have been creating solutions that allow us to achieve the highest levels of cleanliness in such places as hospitals or laboratories. These solutions have found a new, much wider application during the pandemic – no longer protecting the room or manufactured products against contamination, but people against infections. The protective measures used so far in the form of the simplest ones, such as masks, gloves or overalls, as well as the more advanced ones, such as pass boxes, have reduced the epidemiological risk in many large industrial plants. In addition, we have extended our offer with new products that are precisely tailored to meet the existing requirements of health and safety of the employees. Based on our experience in the production of REECO modular industrial furniture, we have developed and introduced to the market in a short period of time a range of mobile dividing screens designed to minimize contact e.g. between two employees working in one room or two restaurant guests dining at one location.

E.E: How will these products / solutions help them in the next period?

M.S: The key issue here is to minimize the risk of epidemics. This is most important for large industrial plants, where tens or hundreds of people can work in one production hall. Detecting even one case of a rapidly spreading infectious disease – such as Covid-19 – can result in the quarantine of the entire enterprise, temporary shutdown of operations and multi-million losses. Security measures such as our mobile screens or personal protective equipment can significantly minimize this risk.

E.E: How did your employees react to the new working conditions?

M.S: The time of the pandemic forced everyone – including us – to make a number of organizational changes. For us – RENEX Group, this meant an even greater transfer of work to previously functioning IT systems. All tasks that did not require on-site work were switched to remote mode. Employees whose tasks required their presence in the company – especially in machine operation and production – were equipped with personal protective equipment and contacts were kept to a minimum. Our employees showed great understanding of the situation and care for their own safety and that of their colleagues. Many employees, knowing that the situation could potentially be difficult for our company, showed particular commitment and additional work to help the company at this particular time. All this showed that RENEX is a real family business and has enjoyed this status since its inception for good reason. This approach has allowed us to avoid any layoffs and maintain full employment at a time when many other companies had to reduce their staff.

E.E: What innovative products / solutions did you come up with to meet the situation?

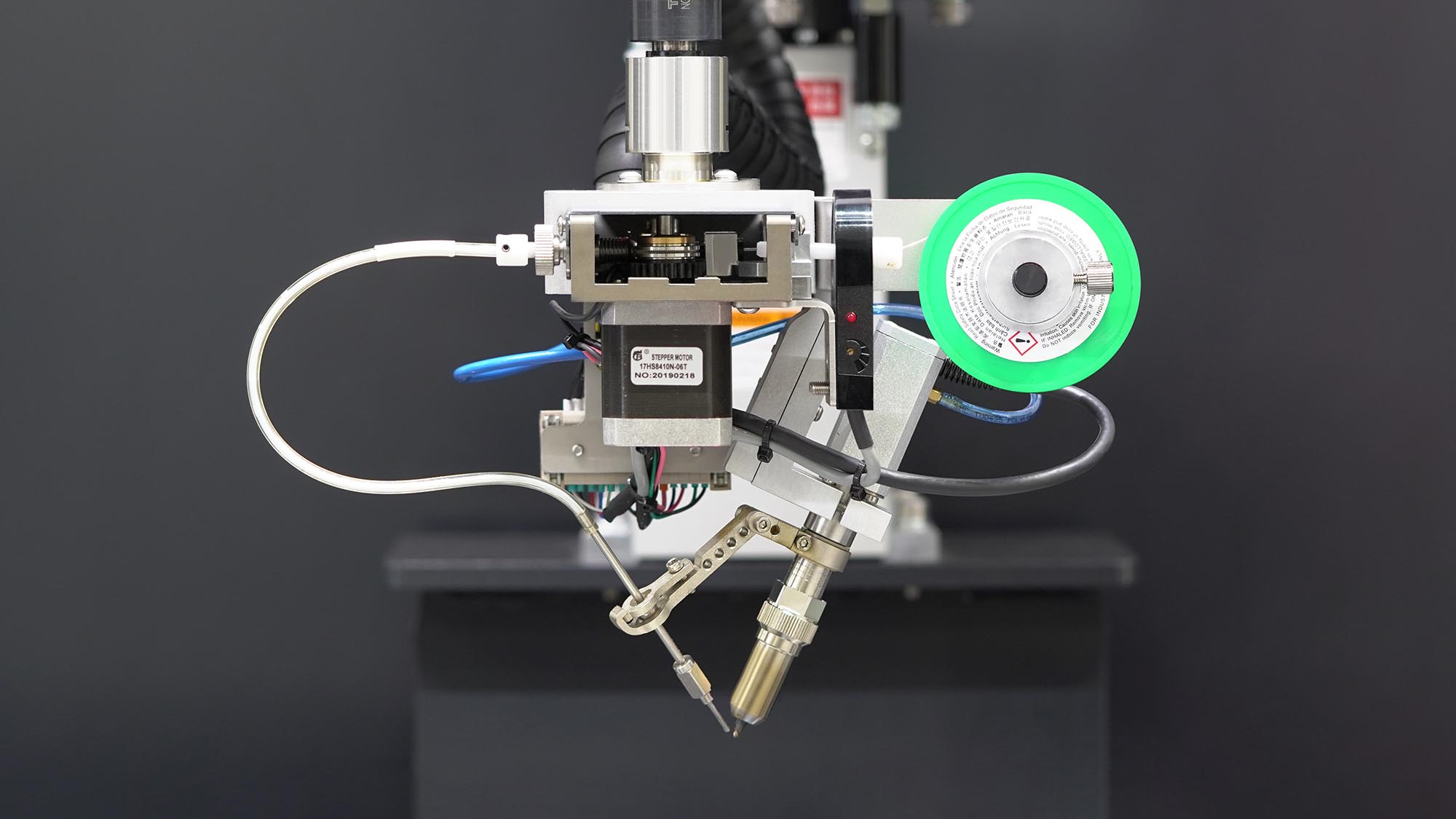

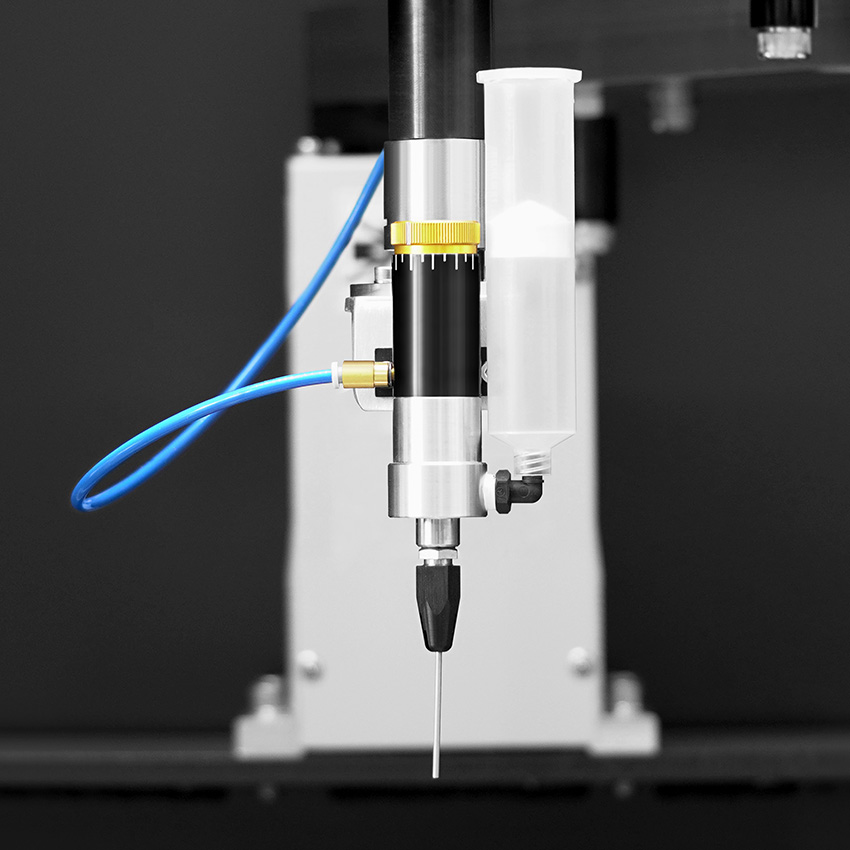

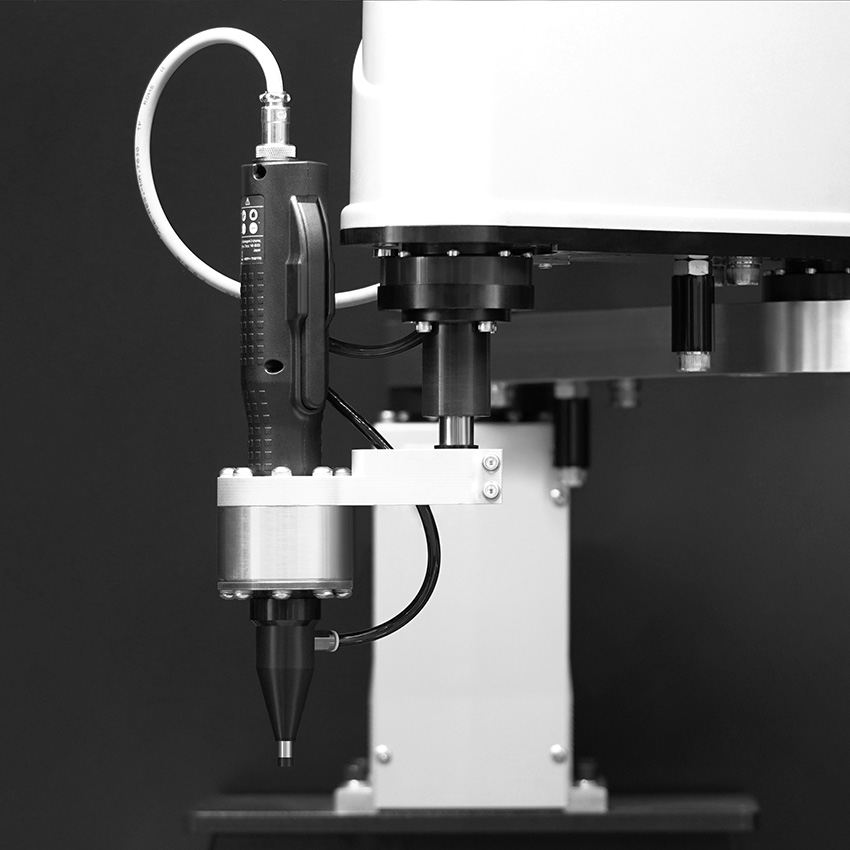

M.S: In addition to the products discussed earlier, our Group has provided our business partners with far-reaching consulting assistance. Using the experience of the entire RENEX Group, we supported companies in the process of automating their production and partial reorganizations in response to the pandemic and subsequent economic crisis. We have developed individual solutions for each entity with whom we have worked with to increase the effectiveness and efficiency of its operations while reducing the risks resulting from the work of people in times of epidemics. It is worth explaining that automation processes are an area very close to us. One of the aforementioned areas of RENEX Group’s activity is robotics. We are a distributor of YAMAHA industrial robots for Central and Eastern Europe, and in the RENEX TECHNOLOGY AND TRAINING CENTRE established by us we develop our own REECO modular robots. We have developed these robots so that as ready-made solutions they can be implemented into existing production lines, replacing humans for tedious and repetitive tasks. Currently, the standard tasks performed by our robots are soldering, screw assembling, dispensing and labelling.

E.E: Under what conditions was the transition from the post-COVID-19 situation to the current one?

M.S: The European and world market has certainly been strongly affected by the Covid-19 pandemic. Many entrepreneurs have still not returned to the figures from before the first, main wave of the epidemic, and already realize that the next one is expected for autumn this year. The economic crisis is present in all branches of industry and its effects are expected to be felt for years to come. In this situation, our main objective is to fulfil the mission of RENEX Group – to support the development of our business partners. We are aware that we have knowledge, experience and technology base developed over the years, which we can use to advise entities with which we have cooperated for years on how to effectively change their operating and production models in order to adapt to the current difficult market requirements.

E.E: What are your estimates for the rest of the year?

M.S: We assume that the epidemiological situation will deteriorate, but this time companies in Europe and worldwide will be better prepared for it. Both in terms of their equipment – in the form of appropriate personal protective equipment and the general organization of the company – through introduced safeguards and business models. Many of our partners have introduced production mechanisms that will enable them to work with a low risk of an outbreak inside the company.

All interested are welcome to contact our branch office in Romania. More information at www.renex.pl.