Rubitherm is a leading supplier of Phase Change Materials (PCMs) and thermal storage systems since 1993 and a founding member of the RAL Quality Association PCM. It produces and distributes PCM materials and systems with several 1,00 t/year PCM delivered worldwide.

PCMs are the materials that absorb or release a large amount of heat during the change of their physical state ‘phase’, in Rubitherm’s case solid-liquid, at their phase transition temperatures working as a thermal battery. This is so-called ‘latent heat’ meaning that the material stores a certain amount of thermal energy without fully changing its phase ideally at a defined point or a narrow range of temperature.

Rubitherm continuously works on the development of PCM products, systems, and PCM encapsulations for specific applications. It also participates in national and international R&D projects, customized projects, support, and application advice.

Interview with Asmaa Ali, R&D Engineer at Rubitherm.

Easy Engineering: What are the main areas of activity of the company?

Asmaa Ali: The applications of PCMs are numerous and can be found in different areas such as peak shifting, waste heat recovery, backup for cooling and heating appliances, thermal buffer, heat and cold storage, and many others. We were strongly involved in the cold chain of vaccine transport during the time of Corona. Our current focus is to deploy PCMs in building and HVAC applications. This is strongly motivated by the rising need for energy-saving products to reach low and net-zero energy buildings contributing to the energy transition.

E.E: What are the ranges of products?

A.A: We offer a wide range of products. Our portfolio is classified as:

PURE PCM materials, Rubitherm produces two main groups of materials: organic (RT-line) and salt-hydrate based (SP-line). Our PCM products are available for a wide temperature range of about -50 °C to +111 °C. As the PCMs undergo a solid-to-liquid phase change, they require encapsulation for their use and implementation.

Encapsulations: Rubitherm produces various finished and semi-finished macro-encapsulated products. Aluminum and polymer containers are filled with different PCMs. Our innovative Compact Storage Module (CSM) is made of an aluminum case with fixed dimensions of 450 x 300 mm and two optional thicknesses of 10 mm or 15 mm. This product is considered as a merit on its own providing great advantages of leak-proof, large surface area, high heat conductivity, and high heat exchange rate through the aluminum housing from the PCM to the medium. The possibility of corrosion is overcome by introducing inner and outer anticorrosive layer. Furthermore, the CSM product provides maximum flexibility to be installed in many applications, mainly HVAC systems of different designs.

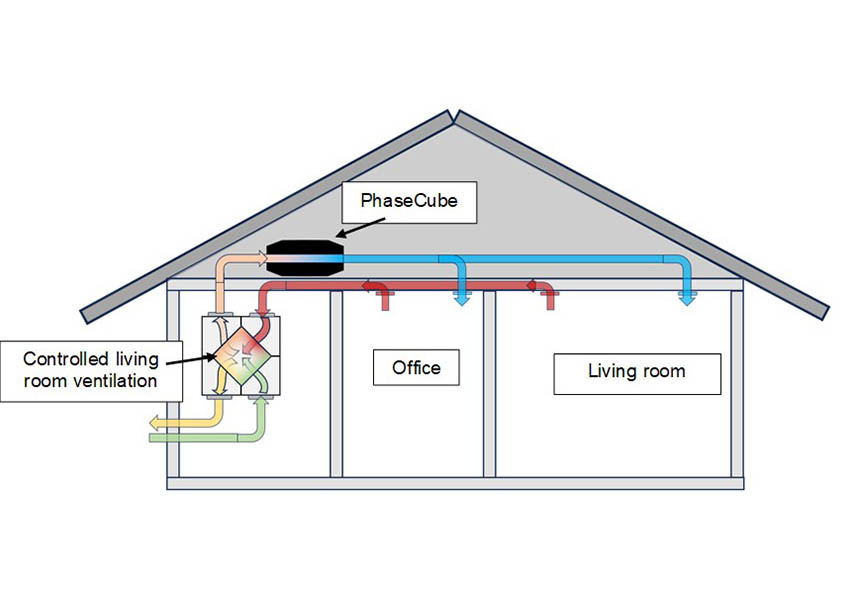

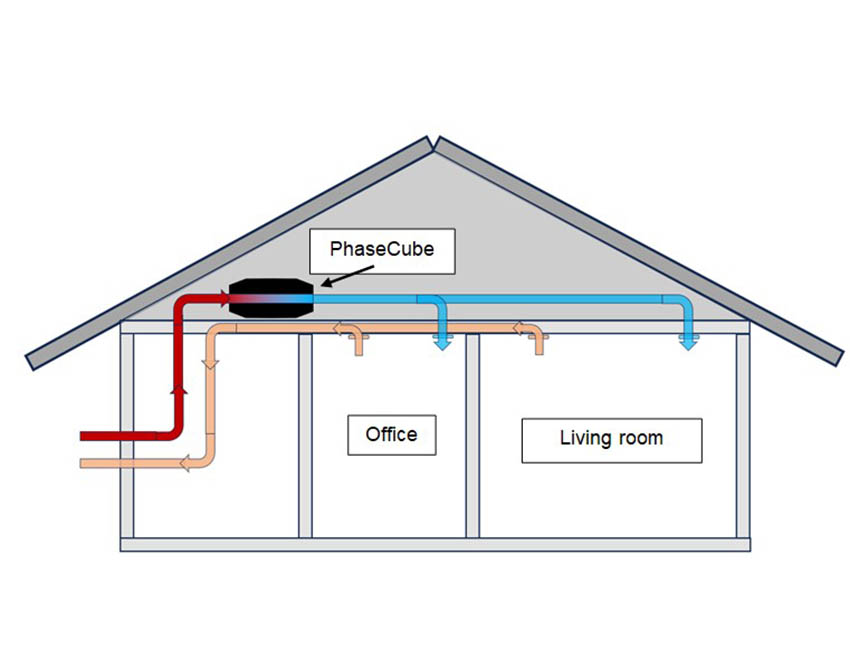

Systems: Rubitherm developed air- and water-based thermal storage systems. The air-guided system called ‘PhaseCube’ is based on the CSM panel. It consists of 10 panels stacked horizontally on top of each other with a suitable spacing for air to flow. With its standard 1000 Wh, it can be integrated into a centralized ventilation system (Figure 1) or as a stand-alone system (Figure 2) providing ease of integration, maintenance, low cost of operation, and no to minimal power consumption.

With the same concept, modular arrangements of CSM panels can be used to increase the storage capacity according to the requirements as illustrated in video below.

Our water-guided storage is the ‘PhaseTube’. Its energy density is up to 5 times higher than that of water tanks. They can be directly installed in the centralized cooling or heating circuit. For large storage capacities, modularly designed storages are combined supplying our customers with units of the required size for their intended use.

E.E: What’s the news about new products?

A.A: Our newest product is ‘PhaseDrum’ which is intended for use in decentralized heat recovery systems. It is an innovative alternative to ceramic heat exchangers that are based on sensible heat only. Due to the high latent heat storage of the PCM, the PhaseDrum prolongs the switchover time of the fan and improves fan switching time. This product is still under development and currently, we are aiming to collaborate with partners from the HVAC industry.

E.E: At what stage is the market where you are currently active?

A.A: We have a good position in different markets especially in buildings, HVAC, cold chain, and automotive industries. We supply our PCMs to big players in different sectors worldwide.

E.E: What can you tell us about market trends?

A.A: We see a large increase and interest in the building sectors especially, data centers and warehouses, as the two sectors consume a lot of energy. Energy consumption costs share a significant portion of the total overhead expenses of the warehouse. Due to the high computing density of the data centers, enormous amounts of power are consumed. This produces great amounts of heat. A cooling system is then required to remove this heat. More heat can even be produced during the high load hours driven by the users. This causes overloading of the cooling system during hours of intensive use and more likely underutilization of the cooling capacity during hours of less use resulting in a diurnal cycle.

Thermal energy storage using phase change materials plays a key role in reshaping the energy consumption profile and achieving the following for both sectors:

Bridging the gap between supply and demand when using renewable energies, for example, PCM in combination with solar energy, PCM stores the produced solar energy during the day in the form of cold around the required temperature to release it when no sun is available for energy production in the most cost-effective way.

- Bridging the gap between supply and demand when using renewable energies, for example, PCM in combination with solar energy, PCM stores the produced solar energy during the day in the form of cold around the required temperature to release it when no sun is available for energy production in the most cost-effective way,

- Savings in operating costs. Long-term grid-energy savings of up to 50%,

- Reduction in the running time of mechanical refrigeration machines and thus simultaneously increasing the efficiency of the machines and extending their lifespan,

- Providing energy security for cooling,

- Using cheap tariff electricity,

- Reduction of CO2 emissions,

- When using PCM, temperature fluctuation is reduced

E.E: What are the most innovative products marketed?

A.A: Our most versatile product is the CSM panel. Thanks to its flexibility in the integration of various ventilation systems such as ‘PhaseCube’ and other designs of air-guided storage and HVAC applications in buildings. We produce and sell several ten thousand of CSM panels annually.

We are also upgrading our pilot line to increase the production capacity by a factor of 2-4, save time and energy, and potentially reduce CO2 emission.

E.E: What estimations do you have for 2024?

A.A: The coupling of PCM storage tanks with heat pumps and even the use of PCM inside the heat pumps have already emerged in Europe and worldwide. The market in this sector is expected to grow faster driven by the need for reliable storages for sector coupling and integrating renewable energy systems. PCM tanks can store heat or cold from renewables when available providing the advantage of the small operating temperature range. Thus, thermal energy storage using PCMs plays a great role in electrifying the heating and cooling sectors. For that, we are working on increasing the heat exchange rate and power of our storage system to provide the market with even more reliable and efficient products.