With an above-average double-digit growth rate in the North American woodworking machines market, SCM, the leader for secondary woodworking technologies, plays a key role at the International Woodworking Fair (IWF) with the largest collection of high-tech applications and services and its “Industry 4.0” latest applicable solutions.

WORK SIMPLE. WORK DIGITAL.

In an innovative booth of over 24,500 square feet, an impressive arrangement of SCM solutions will feature live demonstrations with industry experts available to advise visitors on the most efficient and productive equipment /solutions.

The main focus of the event is the “Work simple. Work digital” concept with the SCM Digital Hub, an innovative control center, and Maestro Digital Systems, the platform of latest-generation smart digital solutions, perfectly integrated with SCM machines, to make every stage of woodworking easier and faster both for small-sized companies and large multinational organizations.

Among the Maestro Digital System solutions, the main emphasis is on the new IoT (“Internet of Things”) platform, Maestro connect, in response to the latest Industry 4.0 requirements: it is a system for collecting and analyzing data retrieved from SCM machines to increasingly monitor and optimize production processes, enabling full control of production performances by the customer and a series of micro services such as, a timely and smart maintenance and an optimized spare parts management. The advantages of the system are increased productivity and decreased downtime, improved and continued operating cost control, lowed maintenance costs and the ability to monitor machine parameters and performance in real time, anywhere and at any time, allowing correction of any malfunction in an increasingly timely manner (smart maintenance).

Popular technology will include the new, latest generation, multi-function, wide-screen and multi-touch operator panel (eye-M), the innovative remote assistance and maintenance system with augmented reality glasses (Maestro smartech), the powerful and versatile Maestro suite, a complete software system for all processing types and methods, as well as the Virtual Reality 3D Integrated Cell Simulation system (Maestro xplore).

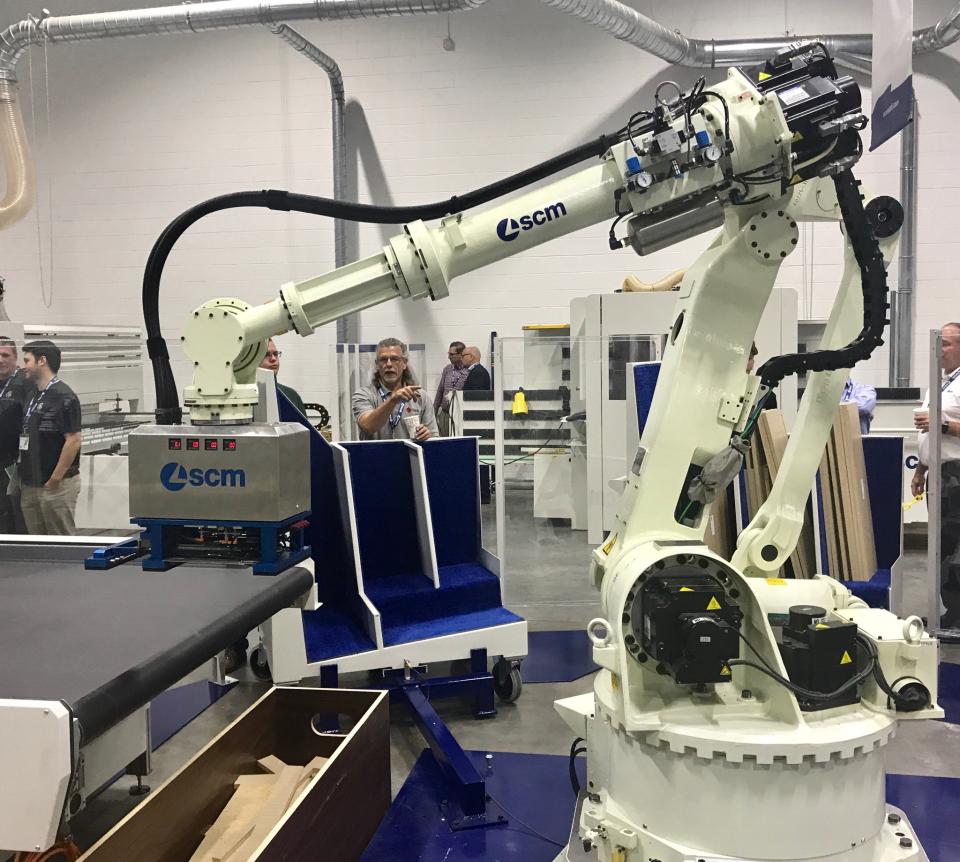

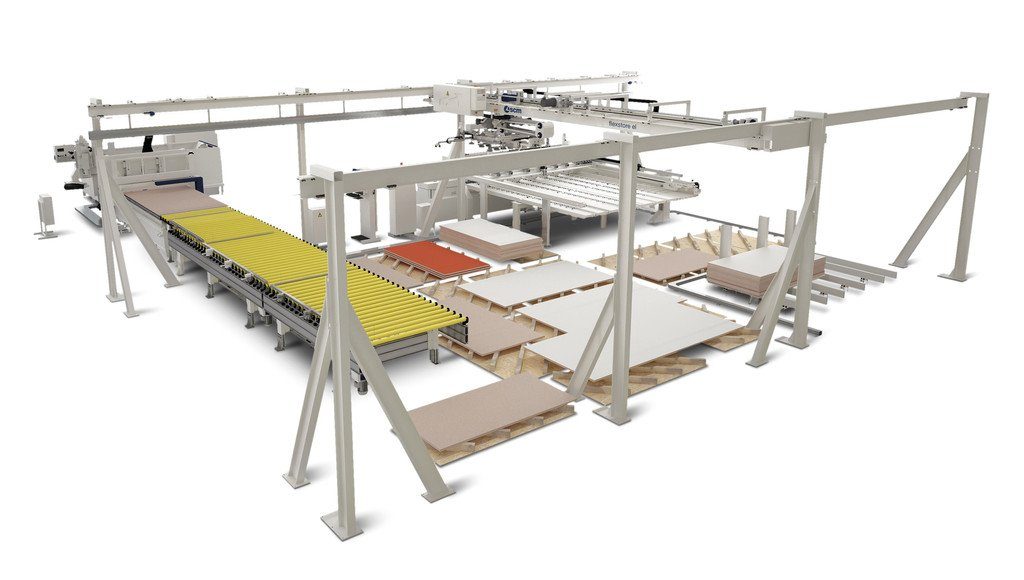

An additional focus of the booth is SCM’s most advanced robotic integration for woodworking technologies. A robotic nesting cell and morbidelli n200 nesting cell will demonstrate full production cycles with automatic label placement, along with loading and unloading nested parts. Smart unloading of the nested parts using an industrial robot will feed the stefani kd edgebander and stack the finished parts. Using a mobile industrial robot, the material will be transported to the next station. At the end of the cell, the cabinets will be assembled, clamped, and fitted with doors and drawers.