With the rising prominence of hydrogen as a clean energy solution, understanding the intricacies of hydrogen compression becomes increasingly crucial. This article serves as a comprehensive guide to navigating the hydrogen horizon, delving into the vital role of compressors and the challenges they face in various applications within the hydrogen value chain.

Introduction to Hydrogen Compression

The global focus on decarbonization has spurred a renaissance in hydrogen technology, positioning it as a cornerstone of future energy systems. As nations rally behind ambitious climate goals, the hydrogen sector undergoes a dynamic transformation, marked by innovative advancements across the supply chain.

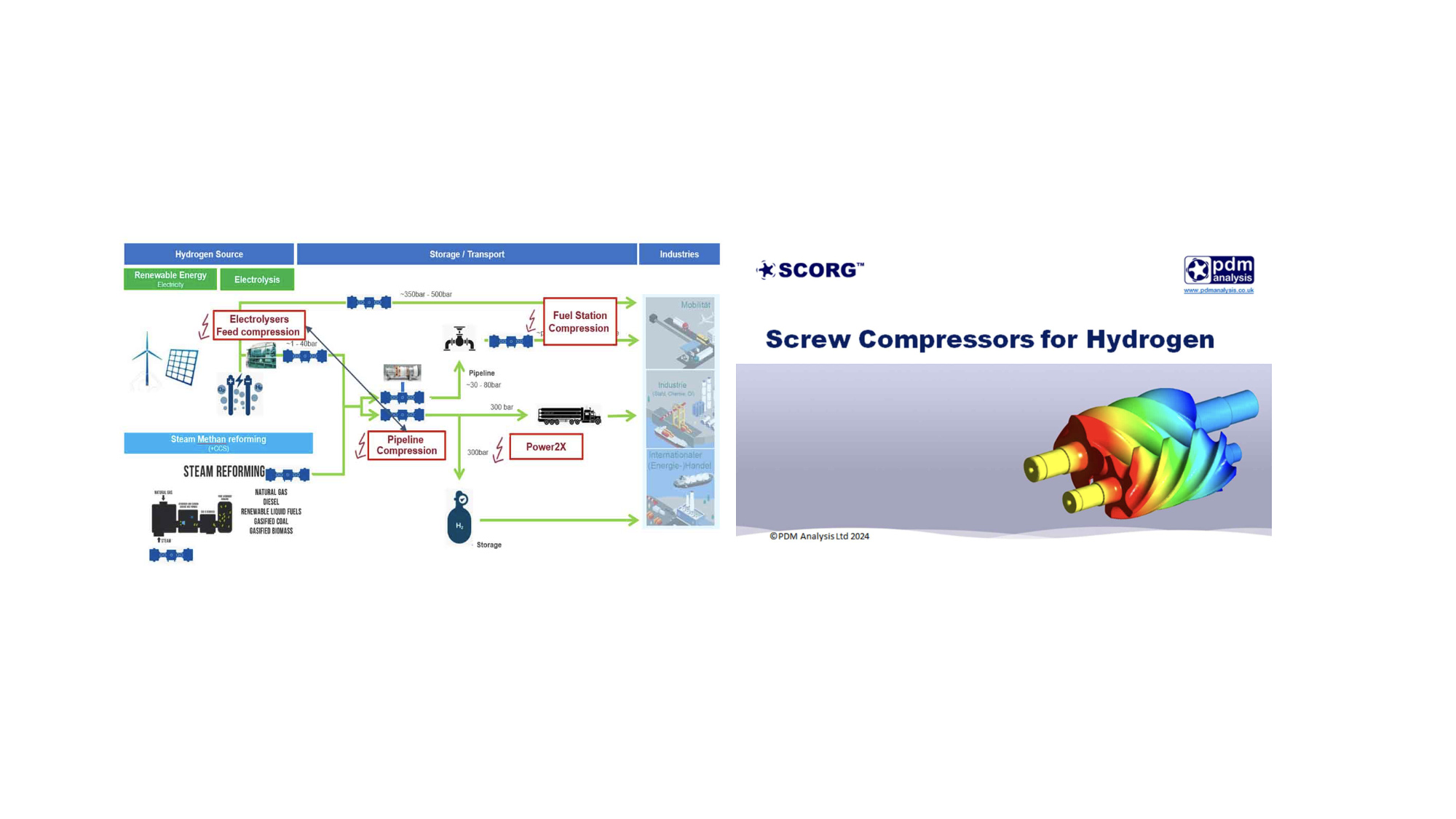

At the forefront of this evolution is hydrogen compression, an essential process that enables the efficient storage, transportation, and utilization of hydrogen. Compressors play a pivotal role in elevating hydrogen to requisite pressures for different applications, ranging from injection into the transport grid to storage and fueling stations.

Read more about Hydrogen compression here.

Applications of Hydrogen Compression

The choice of a compressor is influenced by application requirements, available space, and overall ownership costs. There are generally four identified roles for compressors in hydrogen applications.

1. Injection into the Transport Grid: Compressors play a vital role in boosting hydrogen to required pressures for integration into existing natural gas infrastructure and transportation networks.

2. Hydrogen Storage: Effective compression ensures the stable storage of hydrogen, with options ranging from tank storage sites to underground salt caverns.

3. Fueling Stations: Compressors at fueling stations must accommodate varying discharge pressures and flow rates to support the growing demand for hydrogen-powered vehicles.

4. End-User Demand: Different end-user applications necessitate tailored compression solutions to meet specific capacity, pressure, temperature, and purity requirements.

Read more about the Hydrogen compressor application here.

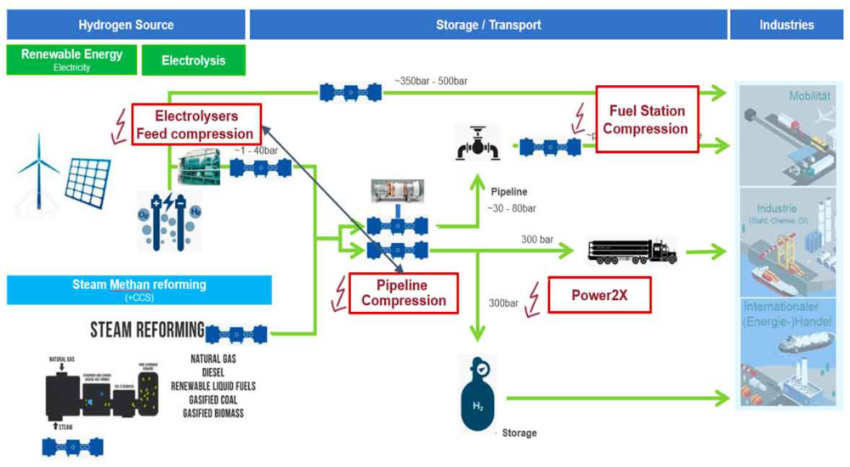

Screw Compressors: Addressing Hydrogen Compression Challenges

Screw compressors emerge as a leading solution for hydrogen compression, offering economic benefits and operational flexibility. These compressors, categorized into oil-flooded and oil-free types, excel in handling high-volume flows and adapting to diverse application demands.

Despite their advantages, hydrogen compression presents several challenges, including:

1. Hydrogen Purity: Maintaining high purity levels is crucial for various industries and applications, necessitating non-lubricated compressors to mitigate contamination risks.

2. Capacity and Pressure Requirements: The selection of compressors hinges on the required volume flow and pressure, with screw compressors limited to specific ranges due to design constraints.

Read more about challenges in Hydrogen compression here.

SCORG: Optimizing Screw Compressor Performance

The SCORG software, developed by PDM Analysis Ltd, is designed to optimize the performance and energy efficiency of positive displacement machines. It is a valuable tool in making your machines more energy-efficient by offering the following features and capabilities.

Try SCORG today by downloading a demo, or the cloud version of SCORG alto.

Performance and Efficiency Analysis

1. Performance Analysis: SCORG software provides a detailed performance analysis of screw compressors and expanders. It can identify areas where energy is wasted, such as excessive clearances or inefficient compression processes.

2. Loss Analysis: SCORG can pinpoint losses in the machine, including clearance leakage losses, friction losses, and other inefficiencies, and provide recommendations for reducing these losses to enhance energy efficiency.

3. Scenario Analysis: SCORG can run various scenarios and simulations to determine the most energy-efficient settings, considering different operating conditions and variables. This includes oil-free and water-injected compressors which have been a main subject of research for project SECRET at City, University of London.

Diagnostics and Recommendations

1. Performance Diagnostics: SCORG can be used as a digital twin of a screw machine to help diagnose performance issues and provide actionable insights for improving energy efficiency.

2. Optimization Recommendations: SCORG provides recommendations for improving the energy efficiency of the machine, such as suggested modifications, operational changes, or maintenance practices to reduce energy waste.

3. Operational Guidance: SCORG can provide recommendations on how to operate machines more efficiently, such as suggestions for maintaining a constant speed or adapting to variable demand.

4. Sizing and Selection Assistance: The software can assist in the proper sizing and selection of PDMs for specific applications, helping users avoid oversizing, which can lead to energy waste.

5. Maintenance Planning: The software can assist with predictive maintenance by identifying potential energy efficiency issues, allowing for proactive maintenance actions. For example, SCORG can calculate bearing loads and subsequently predict the bearing life.

VIsualization, Simulation and Reporting

1. Efficiency Mapping: SCORG can generate efficiency maps or performance curves for your machine, helping users visualize the machine’s efficiency under different operating conditions. This enables operators to identify and select the most energy-efficient operating points.

2. 3D Modeling and Simulation: Advanced modeling and simulation tools can help analyze and refine the design, taking into account fluid dynamics, heat transfer, and stress analysis to create an efficient machine.

3. Data Visualization and Reporting: SCORG offers data visualization and reporting capabilities, enabling users to track and monitor energy efficiency improvements over time.

Energy Savings Estimation

1. Energy Recovery: SCORG can identify opportunities to recover and reuse energy that would otherwise be wasted, which helps in designing heat exchangers or energy storage systems.

2. Informed Decisions: The software can estimate potential energy savings from recommended changes, helping users make informed decisions about investments in machine upgrades or modifications.

3. Design Optimization: Optimization software can help design the internal components, such as rotors, valves, and seals, for optimal fluid flow and reduced friction, thereby improving efficiency.

Read more about SCORG for Performance Enhancement and Optimization of Screw Compressors here.

Conclusion: Towards a Sustainable Hydrogen Future

The future of hydrogen in a sustainable society looks promising, with ongoing forums emphasizing the adaptability of compression techniques and encouraging innovation. With SCORG, you can anticipate market demands and enhance and optimize your compressors to adapt to hydrogen compression needs.

With SCORG, operators and engineers can gain valuable insights into the performance of their screw machines. SCORG provides data-driven insights enabling you to implement measures to enhance their energy efficiency. You reduce energy consumption, operational costs, and environmental impact by enabling machines to operate at their peak efficiency. SCORG is a powerful tool for achieving sustainable and energy-efficient industrial operations.

The efficiency and reliability of compression are indispensable throughout the entire hydrogen energy chain. While established compression methods exist for various facets of the hydrogen cycle, adapting technologies initially designed for natural gas may be necessary. As the need grows for increased capacity, higher pressure, and more intermittent operation, there will be a requirement to extend the current performance of compressors. SCORG will continue to explore the forefront of hydrogen technology and its transformative impact on our world.

About PDM Analysis

PDM Analysis specializes in improving screw machines through smart design, thorough analysis, and effective optimization techniques, all made possible by our innovative SCORG software. This software is tailored specifically for positive displacement rotary machines, such as screw compressors, pumps, motors, and more.

The roots of this software go back to the skilled team at the Centre for Compressor Technology at City, University of London. In 2014, PDM Analysis was founded to further develop and share this technology. Our strong partnership with the Centre keeps us at the forefront of software evolution.

Since our inception, we’ve been dedicated to helping both industry professionals and academics. Our clients include screw machine design engineers, R&D specialists, manufacturers, advisors, professors, researchers, and students working on screw machine projects. We’ve also built global partnerships and collaborated with leaders in Computer Aided Engineering (CAE).

Autor: Ahmed Kovacevic, Director at PDM Analysis Ltd.