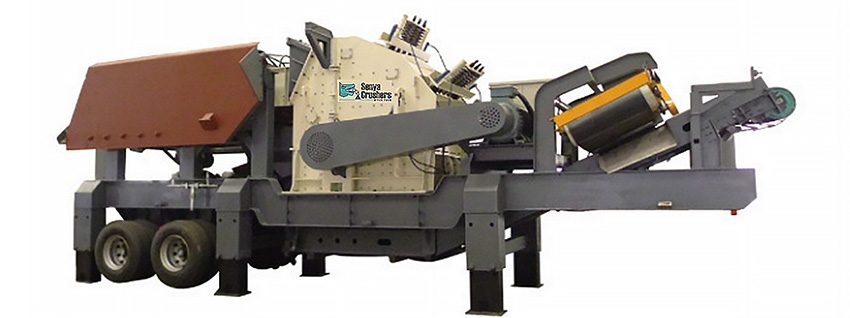

Pioneering a new category in Construction Equipment, Senya Tech continues to add to our revolutionary line of MICRO CRUSHERS with our NEW MICRO Impact Crusher Asphalt Recycler, the Asphalt Eater!

We now have an impact crusher asphalt recycling machine that can easily be pulled with a semi to allow for asphalt recycling on site, effectively removing a major portion of the cost of asphalt. MICRO screen plants and MICRO Conveyors can be added to give an entirely mobile asphalt recycling plant that can easily recycle up to 500 tons per day, be run by a single operator, and load material directly to the dump trucks! And this is all accomplished with electric motors powered by generators and no hydraulics…”WOW!”

Quite simply, there is nothing in the entire world even remotely close to the size, portability, output capacity, and price point of our MICRO Plant machines.

The savings are absolutely real and staggering when you see how it can impact your business!

The two main types of primary crushing units in aggregate processing are the jaw crusher and the impact crusher, each with their advantages. The desired input and output sizes, hardness of material, and desired tons per hour production are the key factors in determining which type is best for your crushing needs.

Jaw Crushers are the standard primary crusher in most cases, as the are able to handle most any hardness of material, and are best for abrasive material which causes more wear on crushing components. In a jaw crusher, 80% of the crushing comes from the material being crushed against itself in the top of the “funnel” of the jaw. The material produced has “fines”, or smaller pieces that then output setting as well as being odd shaped with sharp edges. This can be an advantage and many engineers prefer this material due to it’s strong “setting” the fines provide and the “gripping” edges of the material produced. There’s also the advantage of jaw crushers being able to handle rebar or wire in the material.

An Impact crusher is better suited to softer material as crushes by the blow bars throwing the material against the wall of the crusher.

Impact crushers are better suited to softer material such as recycling concrete and asphalt especially. Asphalt can “gum up” a jaw crusher in warmer weather which is not an issue with impact crushers. Many wait until cooler months to crush asphalt with a jaw crusher, an impact crusher is the perfect solution if that is not an option.

Impact crushers also produce more consistent sized material than a jaw crusher, and the material is more uniform in shape as well as having more rounded edges. The decorative gravel business is also where an impact crusher’s output can be a big advantage.

The future of the aggregate processing industry lies in crushing on site, and Senya Crushers is leading the cutting edge of the technology with our MICRO Plant and it’s capabilities as we pioneer the category. With the addition of a MICRO Impact Crusher to our lineup of MICRO Jaw Crushers, MICRO Conveyors, and MICRO Screen Plants, we have now duplicated every component of major aggregate processing plants on a highly portable, MICRO level. Processing on site is the future, and there’s a ton of money to be made doing it!

Check out our website www.senyacrushers.com for pictures, video, product specs, package deals, and all the Senya Crushers has to offer.

Give us a call, we’d love to tell you more and show you how to get more of what everyone can’t have enough of, PROFIT!

Senya Tech, Ltd.

4801 Glenwood Ave.

Suite 200, PMB 422

Raleigh, NC 27612

919.323.4830