SSI delivers software, services, and expertise for the business of shipbuilding. They take advantage of the rapidly evolving technologies that define the future of the industry and understand how to implement them specifically for shipbuilders.

Interview with Craig Tulk, Product Business Analyst at SSI.

Easy Engineering: A brief description of the company and its activities.

Craig Tulk: In the dynamic landscape of modern shipbuilding, SSI thrives by being a transformation catalyst and a trusted shipbuilding expert. Our mission is to allow shipyards and designers to center their attention on the business of shipbuilding by creating solutions that are natural and easy to use for ship designers, shipbuilders, and ship operators.

A key part of that is being able to act as a trusted advisor and help shipyards implement technology and improve their processes as part of their digital transformation. Specifically tailored for ship designers, builders, and operators, our tools not only address the industry’s unique needs but are also refined based on the valuable feedback of our clients.

E.E: What are the main areas of activity of the company?

C.T: We have over 600 clients worldwide, and we’re always adding more. We are focused on working with shipyards that want to improve their processes and build more ships in less time and on budget. Some of our clients include HII Ingalls Shipbuilding, Austal, and BAE Systems, among many others. More ships in less time and on-budget. Our main sphere of operation lies in creating solutions that shipyards use to develop 3D models for designing, producing, and operating vessels, connecting product information across design, engineering, and manufacturing, and managing that product information throughout the lifecycle.

On the design and engineering side, our initial focus, starting over 30 years ago, was developing software for detail design and production. Since then, we’ve added basic/functional design workflows and increasingly drive production processes directly from our software.

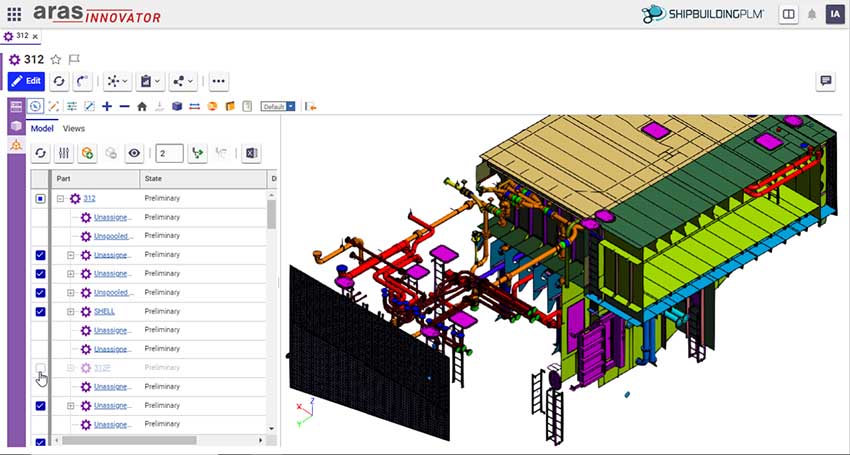

At the enterprise level, we’ve developed the world’s first shipbuilding-specific PLM solution. With that, shipyards manage and organize information, understand change, build a foundation for digital innovation, and support MRO activities.

E.E: What’s the news about new products?

C.T: Our latest innovations include ShipbuildingPLM, locking and configuration control, and modeling project management tools. We have integrated modules for compartment and clash management, design validation, and seamless production output interfacing with shipbuilding machinery. These solutions enhance both productivity and efficiency while ensuring quality control throughout the entire process.

E.E: At what stage of technical maturity is the shipbuilding industry?

C.T: We traditionally help clients create a Digital Twin of the vessel they intend to build. At this point, the concept of a 3D Digital Twin is fairly mature in shipbuilding. Many companies, including ours, have spent a lot of time refining these processes. Despite this, workflows across the lifecycle have been somewhat independent of each other, and that can cause a lot of havoc once you start to build.

But managing information across the lifecycle is a new and exciting area we’re starting to work more in. One example is merging the initial functional design stage with detailed design and production steps. Checking that the functional requirements have been met is becoming easier, and now we can manage all the changes that come up between these two stages of design. That’s where our team’s technical skills and understanding of shipbuilding really shine.

E.E: What can you tell us about market trends?

C.T: The biggest trend in the shipbuilding market is the ever-expanding use of 3D Digital Twins and the increasing amount of 3D detail and metadata being generated. Answering the question of ‘how identical does a twin need to be?’ at different design, production, and operations stages is becoming more and more critical. In the next few years, the future will involve a push to get more detail into these models, but that can also be parsed out for various uses at the level users need them.

Product Life Cycle Management is another crucial development in the industry, underlining the need for these digital models to closely mirror the actual vessel throughout its lifecycle. What I mean is that often, for various reasons, what was designed was not 100% what was modeled for production. What was built from that production model was not 100% true to what was modeled. The trend will be to keep these models true to what was built so they can carry on into the vessel’s future operations and maintenance. The Digital Twin needs to withstand the vessel’s lifecycle, as the concepts of design, build, operate, and maintain all get augmented by using these 3D models and the physical and metadata they contain.

Lastly, the merging of the roles of engineers and 3D designers is becoming increasingly apparent, following a path like automotive, aerospace, and rail. More and more design, even at the preliminary levels, is being done in 3D, and this information can be used further upstream in functional and detail design stages. The push for a more digital, paperless output continues with more processes being driven directly from 3D model outputs, using numeric code, robotics, XR, and learning systems. Other trends include more standardized and open digital formats for better data sharing, designing with future maintenance and upgrades in mind, improved control of information across a fleet of ships, and the increased importance of computer programmers in data management. The rise of remote work, rule-based design, and 3D scanning for various purposes also stand out as significant trends in the shipbuilding industry.

E.E: What are the most innovative products marketed?

C.T: Among our most innovative products are ShipbuildingPLM, and as part of our ShipConstructor product line, new enhancements in weld management, configuration control, project management, and tools to more easily work with sister ships.

For example, WorkShare Graphic Compare allows for the visual comparison of sister ship designs in any area of the project model to get a clear picture of the differences. The visualization can be used to make decisions and communicate differences with stakeholders during the change management process, as a basis for decision-making and communicating differences with stakeholders during the change management process.

Our unwavering focus on vessels and offshore structures drives our offerings, setting us apart in this unique industry.

E.E: What estimations do you have for 2023?

C.T: As we gaze into the remainder of 2023 and the next year, we believe that ship design firms and builders will seek more tailored digital solutions. We anticipate a shift away from proprietary systems towards more open platforms that can better facilitate digital transformation. Our commitment to serving this evolving need remains as strong as ever, and we are set to navigate the change in the industry with agility and foresight. We expect to grow our family of SSI clients in another landmark year.