With steel brushing, grinding and deburring machines, a machine manufacturer from Upper Swabia in Germany offers integral, customised solutions for metal processing. What began as a challenge in its own production led to the successful development of tailor-made machine concepts for the widest range of applications.

The advent of laser technology in metal sheet processing posed a problem for the company: Laser cutting with acid creates an oxide layer which does not guarantee reliable finish adhesiveness. Lissmac Maschinenbau GmbH from Bad Wurzach was searching for a solution to this issue. At the beginning of 2002, the company’s technical management decided to reduce ideas and challenges to a common denominator. A single, two-sided machining system concept was developed. The new technology significantly improved the machining quality of laser-cut components in the Lissmac production. The solution approach was communicated. Collaboration in a regional suppliers’ network and targeted technical exchange on challenges in sheet machining soon made it clear that other companies also needed the highly efficient system technology.

A first prototype of the steel brushing machine (SBM) was constructed, and the machining technology was patented in 2003. The Metal Processing division was born. In 2004, alongside oxide layer removal for improved paint adhesion, the rounding of all workpiece edges was integrated into the system concept and the latter was optimised. A new design and extension of the tool system for slag removal and deburring welcomed in a new generation of machines in 2009.

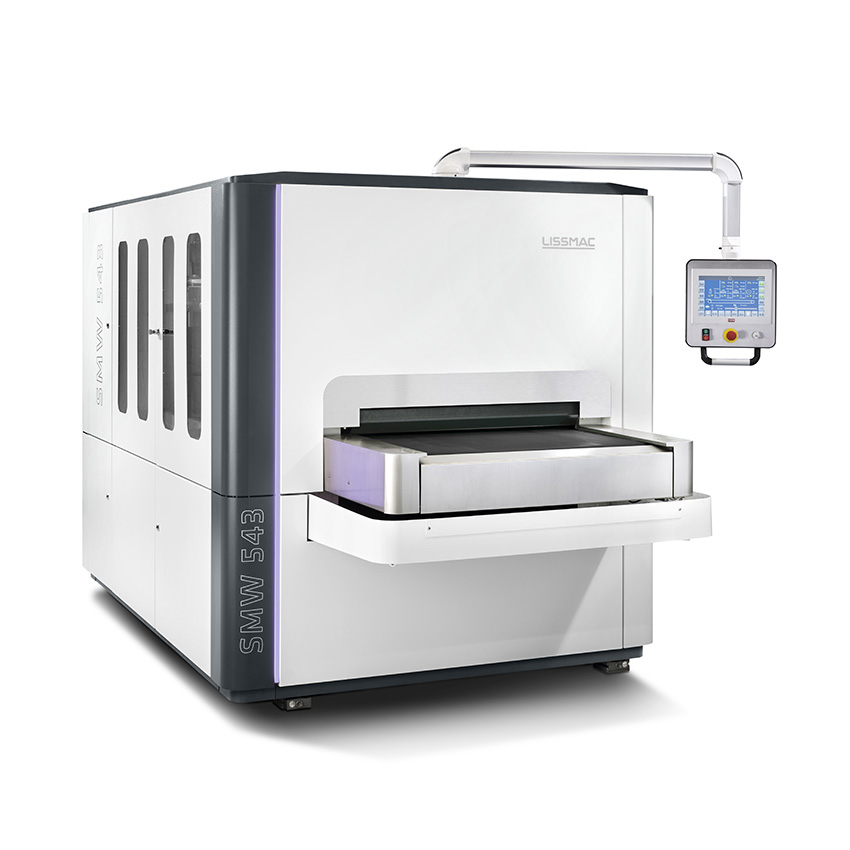

With four different construction sizes of the two-sided processing machines configured according to application, the product portfolio of the Metal Processing field was designed to meet all demands in sheet machining. The acquisition of the metal division of Buetfering Schleiftechnik GmbH in 2012 led to the integration of the premium Steelmaster brand, broadening the product portfolio further still. Freely configurable systems could be offered to the customers. As well as deburring and edge rounding, these systems enabled the creation of a specified surface grind in wet and dry processing. A new milestone was reached in 2015: Lissmac presented a system concept for the two-sided machining of small pieces in a single operation and with a single operator. And in 2018, Lissmac took over the after sales business for the metal grinding machines on the market manufactured by Paul Ernst Maschinenfabrik GmbH, further developed selected technologies and meaningfully integrated these into the existing product portfolio.

Various machine concepts implemented

The system which was originally intended only as a solution to an in-house problem ended up as the basis for the development of three different, successful machine concepts.

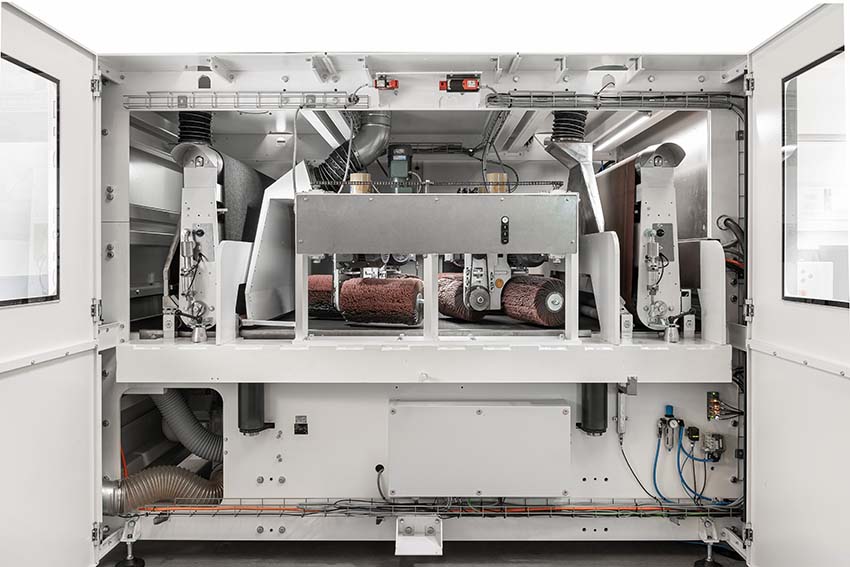

They come together in a system which allows efficient two-sided machining of all cut contours (outer and inner contours) of sheets in a dry machining process in a single operation. The synchronous machining offers extremely high productivity in the production process, say Lissmac. The systems portfolio includes four machine model ranges, differentiated by working width and number and type of workpiece machining units.

The product range of single-side operating dry grinding machines includes some of the particularly low-priced entry-level models, with an application spectrum ranging from deburring and all-sided edge rounding to the removal of heavy plasma or thermal cutting slag. The range is completed by the versatile models from the SMD 3 series among others. The machines stand out for their innovative rotor head technology, alongside other aspects. The application spectrum ranges from slag removal through deburring and even edge rounding up to a radius of 2.0 mm, to surface machining and small-piece processing.

And the freely configurable wet-grinding models will impress, especially with their customised machining of high-value components and mixed materials, confirm Lissmac. Their modular construction and up to four machining units also allow these machines to be flexibly tailored to changing customer requirements.

With its four business areas of Construction Technology, Metal Processing, Machine Tools Handling and Plant Engineering, and 7 sites in Germany, USA, China, Russia, Sweden and Dubai, Lissmac Maschinenbau GmbH is one of the most successful players in international machine construction today.

LISSMAC MASCHINENBAU GMBH

Robert Dimmler, Sales Director, Lanzstraße 4

D-88410 Bad Wurzach, Germany