Rutronik Elektronische Bauelemente is one of the leading distributors in Europe. More than 1,800 employees achieved sales of 1.13 billion Euro in 2021. With 80 offices in three continents, the company has transformed since its founding in 1973 into a global player.

Interview with Roxana Nita, Country Manager Romania at Rutronik Elektronische Bauelemente GmbH.

Easy Engineering: How do you see sustainability and what are your efforts in this direction?

Roxana Nita: Particularly in discussions with our business partners, we are noticing that the topic of ‘sustainability’ is increasingly coming into focus. This concerns both our manufacturers and our customers. We expressly support this development, because environmental protection and the careful use of resources can only be successful if the entire supply chain makes its contribution.

Since we know the needs of the industry exactly and rely on consistent customer orientation, we align our product portfolio accordingly. As a result, components are now available for which ecological aspects have been taken into account throughout the entire product cycle. Our team of experts advises our customers in this respect. With appropriate components, Rutronik thus supports its customers in developing energy-efficient devices and applications that comply with the EU Ecodesign Directive, for example.

In addition, we regard our broadband range as a contribution to environmental protection: the more components are sourced from one channel, the less transport is required, and the better we can match the components to each other as optimally as possible. Our premise is to exert a positive influence on the purchasing behavior of our customers.

E.E: Tell us about sustainability in production & distribution.

R.N: More than 20 years ago, we invested in a comprehensive environmental protection management system to make our contribution to environmental protection in the logistics sector as well. This system is certified according to DIN ISO 14001. In addition, we focus on efficient and automated processes and on reducing the use of packaging materials as much as possible. At the same time, our ESD / Dry Pack packaging system ensures that no damage occurs to the goods. Damaged electronic components represent a major environmental burden, and we want to avoid this.

The cardboard packaging used by Rutronik consists of at least 76 % recycled paper.

The ESD air cushion foils used as filling material have recently been converted to 50 % recycled content while retaining the same ESD suitability. Reusable packaging systems are also used by some major customers.

E.E: Tell us about R&D and innovation.

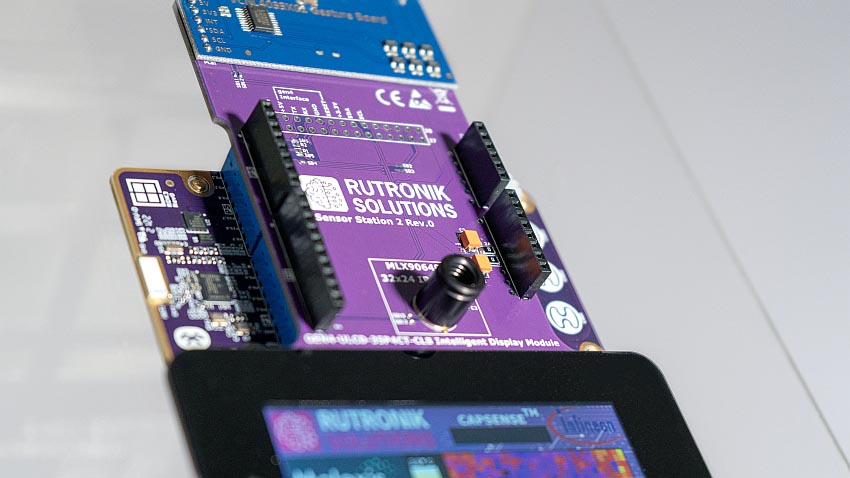

R.N: We at Rutronik believe that an investment in R&D means shaping growth actively. Our consistent focus on growth includes investment in our own research and development capacities. We are aiming at developing new technologies on the one hand and on the other hand at designing highly innovative solutions – precisely tailored to our customer’s needs and the expectations of their end users. With Rutronik System Solutions, we have been growing from a successful broadline distributor to a system provider. Our long-term success is nothing that happened over night: During the last 50 years, we have focused on sustainable and reliable growth to assure the future of our company – for our clients and also our employees.

Digital transformation is setting the pace for growth in global markets. Additionally, artificial intelligence acts as a further accelerator. New materials and composites become fundamental for consumer products. They become key to performance enhancement and play a major role in shaping the technological future. In many cases, they are essential for the functionality of new applications and a decisive factor for access to growth markets.

E.E: What is the company strategy to reduce environmental impact?

R.N: At Rutronik, positions such as Field Application Engineers, Business Development Managers, Field Sales Representatives, and Product Marketing Managers are set up regionally.

This has two advantages: We are even closer to our customers because we are directly on-site with them. It also gives us better access to junior staff – in the regions where we need them.

We also have clear guidelines for dealing with business trips. We have to avoid unnecessary rallies. Of course, we still travel to our clients, but the direct and personal exchange still offers a benefit that is not feasible through online meetings alone. Traveling just for the sake of traveling is not an option for us.

E.E: Tell us about preserving resources and driving circularity.

R.N: The requirements for products from the perspective of environmental protection have risen sharply in recent years. Standards and regulations such as RoHS, the EU chemicals law REACH, the EU Ecodesign Directive, and international regulations such as China-RoHS, TSCA, Proposition 65 list are worth mentioning here. We are also no strangers to topics such as IMDS, Conflict Minerals, WEEE, ELV, and SVHCs. Our team of experts is always on hand to advise our customers and point out special features of the products. We are also in contact with our manufacturers to ensure a continuous exchange of information along the entire supply chain – especially with regard to sustainability aspects.

Roxana Nita, Country Manager Romania at Rutronik Elektronische Bauelemente GmbH.

E.E: Tell us about sustainable energy solutions used.

R.N: A responsible and careful approach to the environment and natural resources is an integral part of our corporate philosophy. This is also reflected in our construction measures and equipment: topics such as energy efficiency and environmental protection are already taken into account in the planning phase.

In 2010, we began installing photovoltaic systems at our logistics center in Eisingen and at our headquarters in Ispringen, which now have a combined total PV output of 1,137 KWp. Last year, the systems covered about 46 % (1,071,162 kWh) of our entire electricity demand for the headquarters and the logistics center. This enabled us to achieve emission savings of around 643 tones of CO2, compared to grey electricity purchases.

In addition, we completed the complete switch from heating oil to gas in 2019. Rutronik has implemented an annual CO2 reduction of approx. 215 tones through this substitution.

Since October 2022, we have newly installed the position of Sustainability Manager in the area of our quality management to continuously develop and implement customer requirements.

E.E: How do you see sustainability in the future?

R.N: We have identified several future key markets for our strategic approach, which have one thing in common: A resource-conserving, responsible yet efficient beginning-to-end policy which is more and more crucial for successful business models. Sustainability is not about having a choice because of our finite resources on Earth. Sustainability is more a kind of essence of future technologies.