Synersight is a family-owned company based in Valladolid (Spain) with international reach. Since 2018, they have been providing specialized intralogistics solutions in workflow automation with autonomous vehicles (AGVs/AMRs).

Interview with Miriam Pérez, Marketing & Communication Manager at Synersight.

Easy Engineering: A brief description of the company and its activities.

Miriam Pérez: As a B2B company targeting the industrial market, we offer the most cutting-edge technological solution tailored to our customers, utilizing the most advanced technologies in the automation sector. The trust of over 250 satisfied clients has enabled us to achieve successful implementations.

We have over 10,000m2 dedicated to manufacturing, R&D, after-sales service, and administration.

We hold ISO certifications in the areas of quality management, environmental management, occupational health and safety, and information security (ISO 9001, ISO 14001, ISO 45001, ISO 27001). Additionally, we are accredited with the “Innovative SME” certificate from the Ministry of Economy, Industry, and Competitiveness, and the Ecovadis certificate, thanks to our strong commitment to sustainability.

Our mission is to develop and integrate innovative technology that improves productive processes sustainably and safely.

Our vision is to provide transversal technology for the automation of industrial intralogistics flows.

E.E: What are the main areas of activity of the company?

M.P: Our main areas of activity are:

Consultancy, Studies, and Customized Solutions: We carry out projects tailored to the needs of each client, offering high adaptability and quick response to cover all necessary aspects for workflow automation. We seek the most cutting-edge technological solution by applying the most advanced technologies in the automation sector.

Design and Manufacturing of AGVs and AMRs: We offer standard and custom products in the design and manufacturing of AGVs and AMRs. We perform integrations, development, and implementation of AGVs and AMRs through our own software, VSystems.

Implementation Service: Before starting implementation work, our Project Managers provide a detailed definition of the timelines for each phase of the project and the necessary resources. Implementations are carried out in very short periods of time, minimizing interference with our clients’ daily work. We offer our own daily work tracking system for immediate response to deviations.

After-Sales Service, Maintenance, Training, and Spare Parts: From our After-Sales department, we provide comprehensive technical support for the optimal maintenance of machines and installations. We offer a wide range of customized training according to each client’s needs. Clients have the freedom to choose the type of service that best suits their needs, including the possibility of contracting remote technical assistance for greater flexibility and reduced response times.

E.E: What’s the news about new products/services?

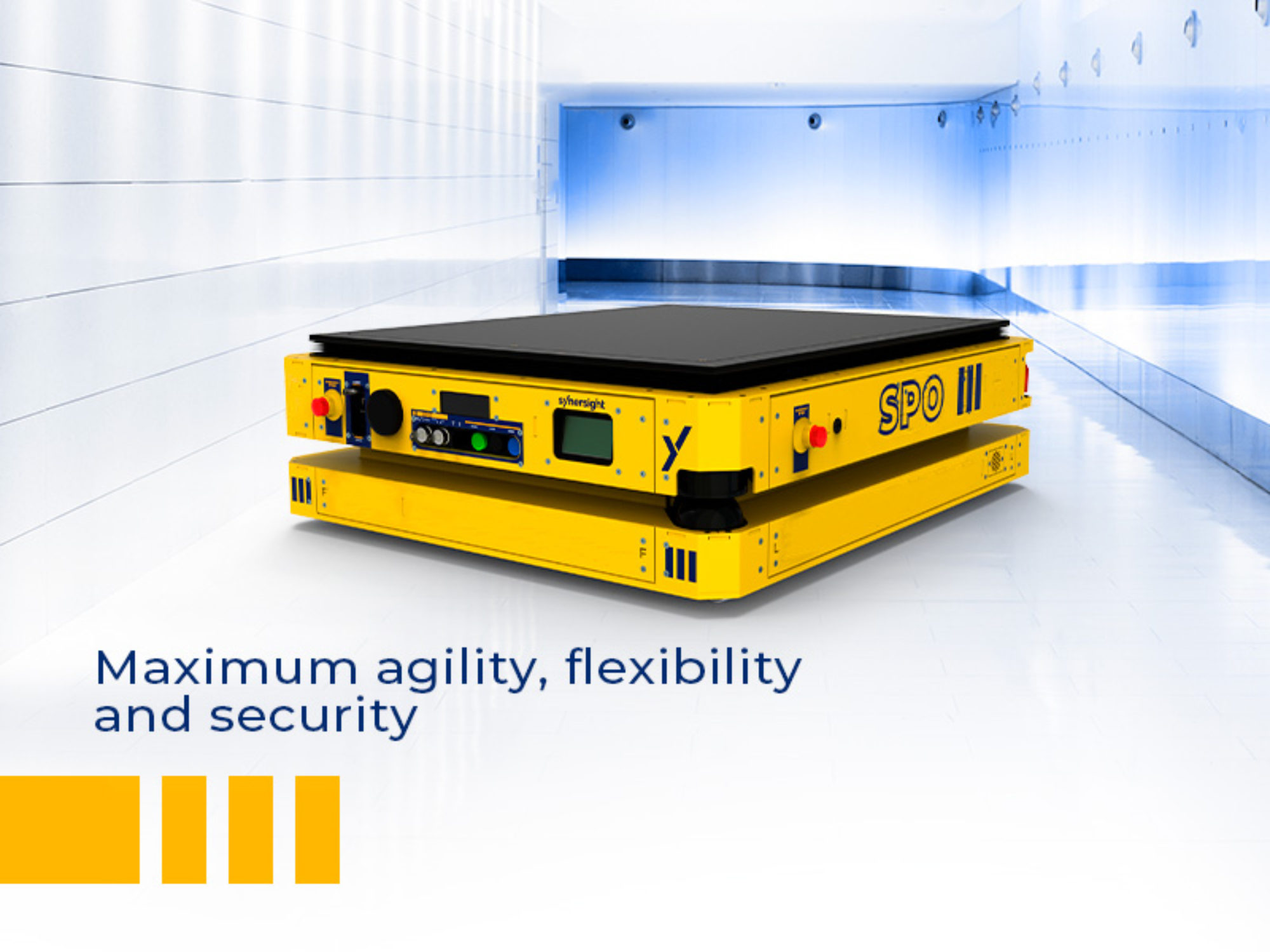

M.P: Our latest product innovations include the SEL, an autonomous stacker, and the SPO, an Automated Mobile Robot (AMR) platform, both based on VSlam technology and compliant with ISO 3691-4 regulations.

The SEL is a high-tech machine designed for lifting and transporting palletized goods. It combines high-performance capabilities with an exceptional level of safety and maneuverability, thanks to its four safety scanners that protect the machine from all four sides. Additionally, it is equipped with an indoor navigation system using reflectors, providing enviable precision and repeatability.

On the other hand, the SPO is a mobile platform that ensures great maneuverability and facilitates intralogistics processes, with dimensions of 1281x1081x365.5 mm and a load capacity of up to 1,500 kg. This new model represents a significant advancement in logistics automation, thanks to its VSlam technology for natural navigation. Furthermore, like the SEL, the SPO meets the most rigorous safety standards.

At Synersight, we take pride in offering innovative solutions that revolutionize logistics automation, and both the SEL and the SPO are clear examples of this.

E.E: What are the ranges of products/services?

M.P: Our Company offers a wide range of products, including:

- Mouse Range

- Towing Range

- Platform Range

- Forklift Range

Each of these ranges is designed to meet different needs in logistics automation, providing tailored and efficient solutions for our clients in different sectors.

E.E: What is the state of the market where you are currently active?

M.P: Currently, the market in which we operate, the automotive sector, is undergoing a significant transformation towards automation and digitization to enhance efficiency and productivity in manufacturing and logistics processes. In response to this trend, we are seeing a growing demand for automation solutions such as AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots).

These systems offer greater flexibility and efficiency in material handling and mobility within production facilities and warehouses. Additionally, they enable companies in the automotive sector to optimize resource utilization, reduce operating costs, and enhance workplace safety.

Despite current challenges such as supply chain volatility and global competition, we see an exciting opportunity to continue providing innovative solutions that help our clients stay competitive and adapt to market changes.

E.E: What can you tell us about market trends?

M.P: Regarding market trends, we have observed a significant increase in demand for automation solutions across various industrial sectors, including the automotive industry. This is driven by companies’ constant pursuit of improving efficiency, productivity, and flexibility in their operations.

Additionally, it’s important to highlight that many companies are adopting a more sustainability-focused approach. In line with the United Nations’ Agenda 2030 goals, many organizations are working to align their operations with the principles of sustainable development and contribute to the achievement of the Sustainable Development Goals (SDGs).

In this regard, we observe a trend towards greater integration of automation technologies such as AGVs and AMRs, not only to enhance efficiency and productivity but also to minimize environmental impact. Companies are seeking to optimize their processes, reduce costs, and improve quality by implementing automated systems that enable more efficient material management and greater agility in responding to changes in market demand.

Furthermore, we are witnessing a growing interest in digitization and connectivity, with a focus on Industry 4.0, aiming to enhance real-time operations control and facilitate data-driven decision-making.

In summary, current market trends point towards increased adoption of automation and digitization solutions, with the aim of improving operational efficiency and competitiveness in an ever-changing business environment.

E.E: What are the most innovative products/services marketed?

M.P: In addition to our highlights products, the SEL and the SPO, we also want to highlight the SPU platform. Like our other products, the SPU platform meets the highest safety standards, including ISO 3691-4 regulations.

At Synersight, safety is paramount, and we continuously work to ensure that all our products meet the highest safety standards.

By offering a range of innovative and safety-focused products, we are committed to providing solutions that not only drive productivity but also protect our customers and their operations. We remain dedicated to innovation and safety excellence in all our product offerings, and we are proud to be leaders in the automation industry in this regard.

E.E: What estimations do you have for the beginning of 2024?

M.P: By the beginning of 2024, we are projected to solidify our presence in the international market. We intend to expand our global footprint by establishing strong relationships with new business partners and penetrating new markets, while also strengthening our relationships with existing customers. Additionally, we plan to continue innovating in the development of new solutions and enhancements for our current products, maintaining our commitment to quality and safety.

Aligned with this objective, we will actively explore new emerging technologies and market trends to remain leaders in our sector. We are committed to offering our customers cutting-edge solutions that meet their needs in an ever-evolving environment.