P.W. BUD-MASZ is one of the largest producers in Central and Eastern Europe, working for customers since 1990. Over 30 years of experience allowed them to gain clients all over the world. What their clients value the most is not only the high quality of the products, but also the company’s flexibility and individual approach to each customer’s needs.

Easy Engineering: Which are the fields of activity where you are operating?

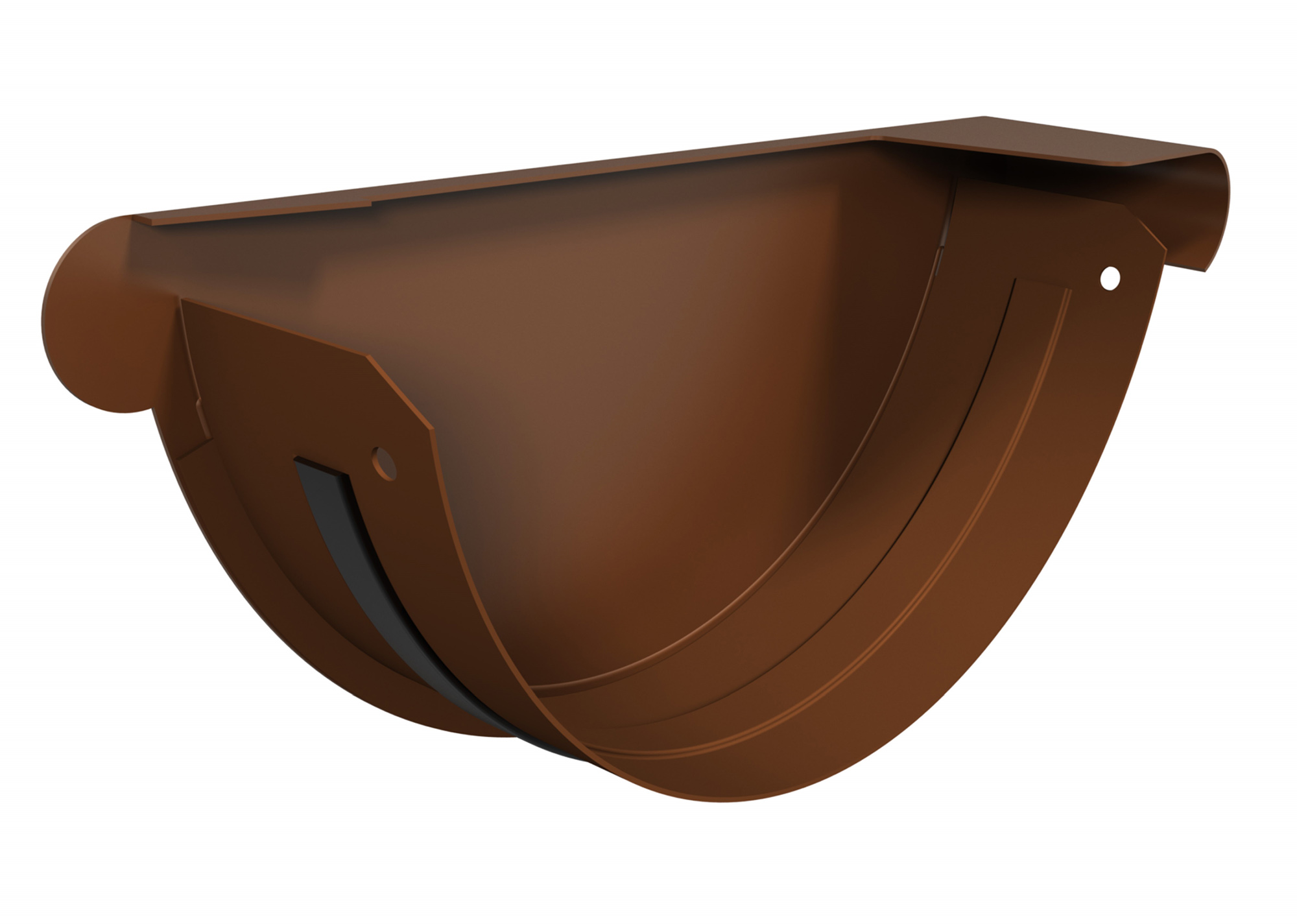

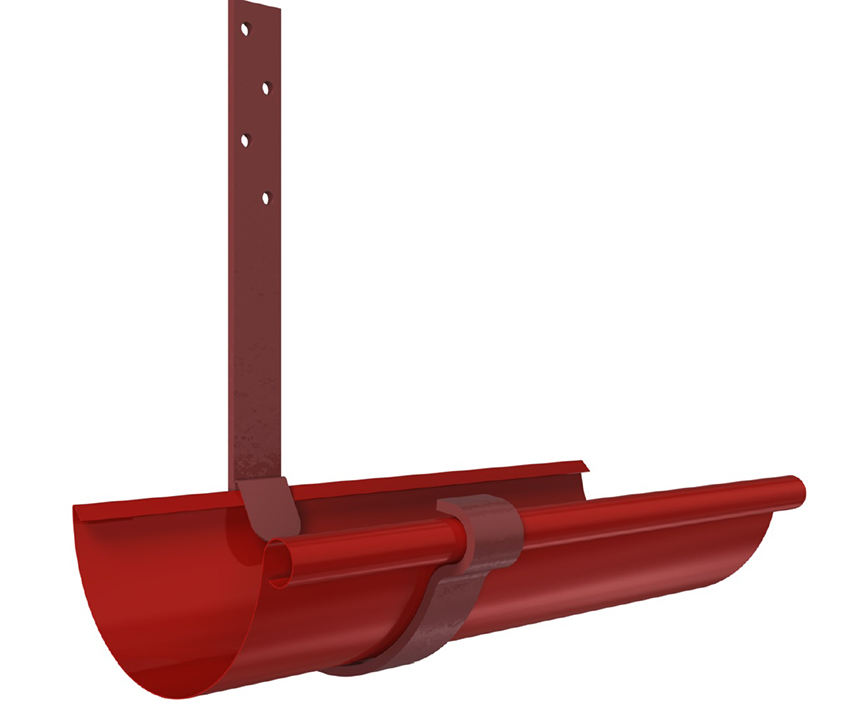

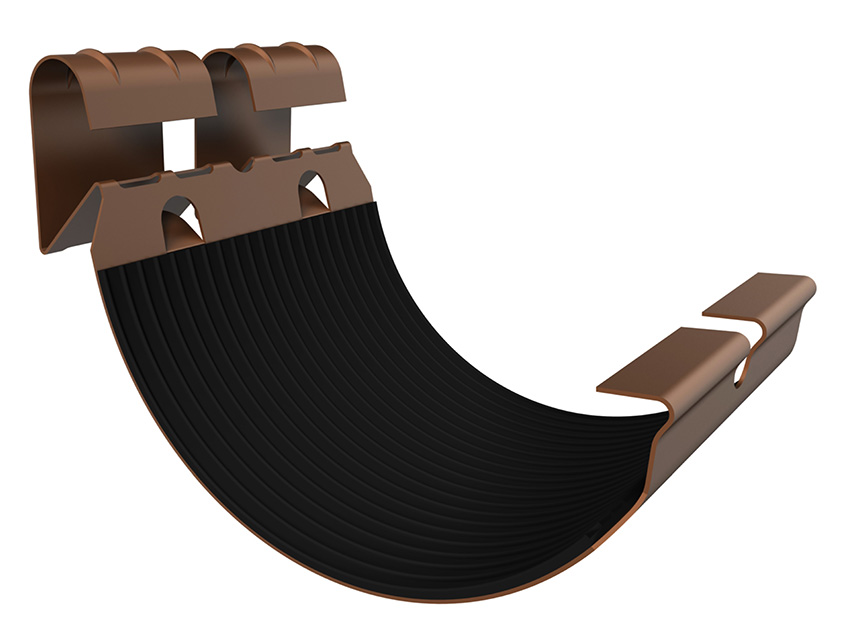

BUD-MASZ: BUD-MASZ is mainly focusing on the production of roll forming machines for profiling sheet metal, metal rainwater systems and aluminum sound-absorbing panels used to suppress traffic and industrial noise. Our products are already proven on all continents and meet expectations in all conditions.

E.E: Which are the most significant projects from 2021?

BUD-MASZ: The most significant project was a creation of robotization system for rainwater system production, which allows not only to produce faster but also to avoid certain mistakes that originate from human factor.

E.E: What projects were the most challenging?

BUD-MASZ: One of the most challenging project was the Star – machine which allows six different types of trapezoidal metal sheet to be produced. This system revolves around changing cassettes automatically, which allows quick change of profiling rolls and immediate production of metal sheet pattern necessary. The complexity of the line and the number of different compounds that were used during every stage, starting from concept and designing to finally putting machine in function, has proven to be one of the biggest challenges our company ever had.

E.E: What are the usual challenges you encounter?

BUD-MASZ: The biggest issue many companies face now, is the growing demand for different types of metal. Therefore, it is hard to obtain sufficient amount of raw, high quality material for the production. Also, due to COVID-19 pandemic, it is difficult to find new, highly qualified workers, who are not afraid to take up new challenges every day.

E.E: How did you overcome the challenges?

BUD-MASZ: Our specialist keep searching for new opportunities and suppliers. We also actively search for new employees, who could join us, to learn new things every day and develop their skills and knowledge.

E.E: What products / solutions were used in the projects?

BUD-MASZ: Nearly all of our machines differ from each other, as we adjust to our customers’ needs. One of the most popular solutions in our machines is installing of crocodile – device that makes introduction of metal sheet into the machine easier.

E.E: Why did the clients choose your products / solutions?

BUD-MASZ: The clients choose our products mainly because they are able to work for many years. We also try to meet the client’s expectations on the designing stage and adjust the project to their individual needs. Thanks to our individual approach, our clients come back to us to produce other machines.

E.E: How were these products/solutions used to optimize the client’s business?

BUD-MASZ: Our machines allow customers to work 24/7 and therefore they can increase production. Our machines also help them to adjust to market needs better.

E.E: What innovative features do the products / solutions have?

BUD-MASZ: This year we changed cooling system for gearmotor in our machines. It allows the machine to keep working even in high temperatures.

E.E: What are your forecasts for 2022?

BUD-MASZ: In 2022 we hope to keep growing and developing, despite many hardships that companies face due to the pandemic situation. As we invest in new machines, we hope to be more efficient and produce machines faster.

Next year we also plan to introduce new patterns of metal roof tile.