When you can call yourself the world’s leading player in the field of large 3D printers, you’re doing something right. With a relatively young team, CEAD has been on the rise for eight years. Yet the Delft-based company is also still in its infancy and seems far from its peak. How did two former TU Delft students manage to get their machines to all corners of the world? Passion for technology and a seemingly unstoppable dose of enthusiasm seems to be the answer.

CEAD’s birth story is a classic. The company’s founders, CEO Lucas and CTO Maarten, at the time students at TU Delft, started CEAD from a garage box near the university. To easily combine working out their entrepreneurial idea with studying. From that moment they slowly grew into the internationally operating company of today. Not surprisingly, CEAD is no longer an unknown name to almost all players in various industries (from the maritime industry to automotive and train builders). For those who are still unfamiliar with the name, Lucas is happy to explain CEAD’s success.

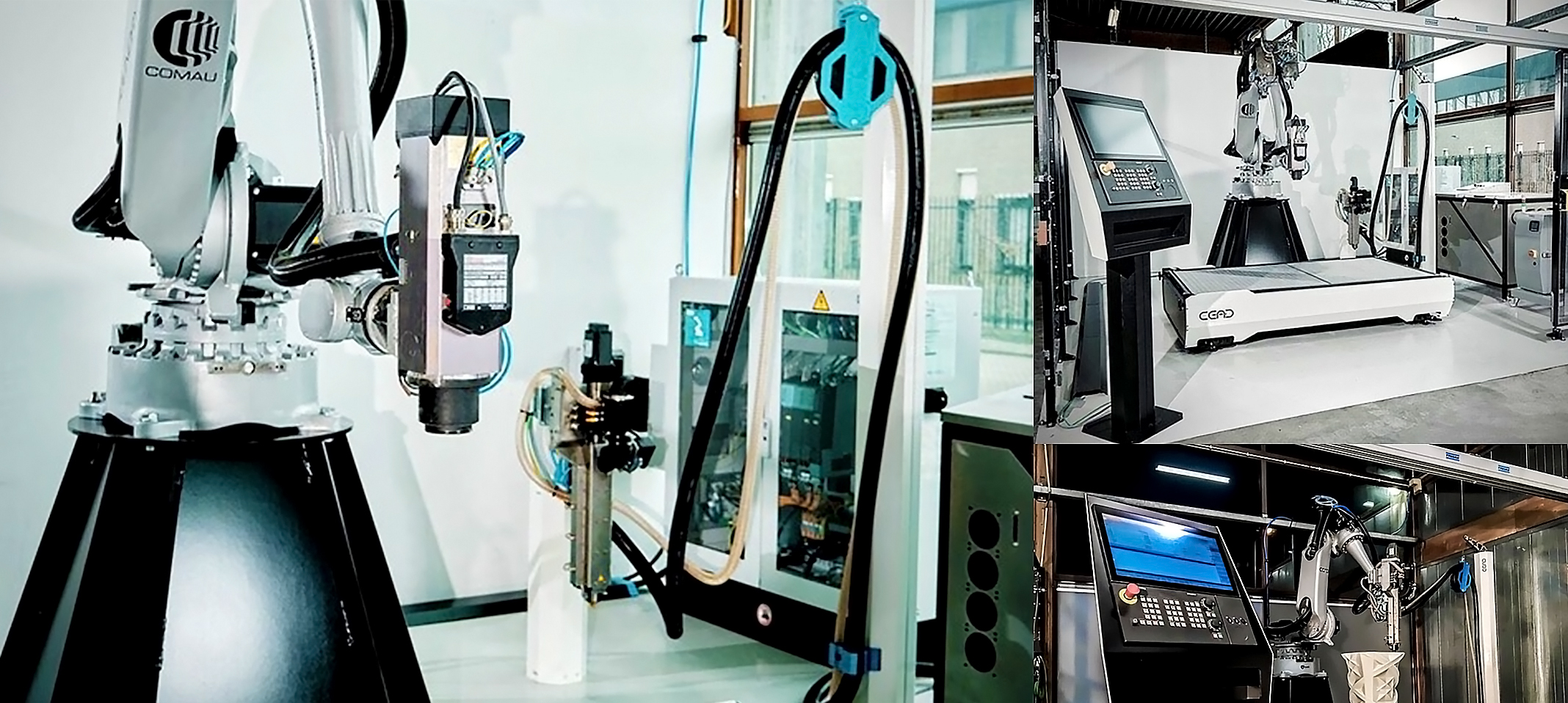

“With our gantry based machines and robot based machines, you can basically print individual parts or even entire boats. Later this year, for example, we are installing our largest system ever at a yacht builder’s facility. It can print objects up to 36 meters. But our printers also make parts for cars, trains or buildings. Currently, the creation of large parts is almost always a manual task. This is often because the construction is so difficult to automate. Not a problem in itself, of course, except that no one is actually trained for it anymore. And many people don’t want to do that kind of work anymore either, because it’s hard work and not always healthy. That’s why you see a lot of production in Asia. And that can cause problems, especially with globalization. Production is sometimes scaled back because of international conflicts. In addition, transportation is also becoming more and more expensive. All this added up means that it will become a lot more interesting again for companies to see if it can’t be produced locally after all. A bit of the countermovement of globalization.”

Lucas and Maarten have not always been concerned with large 3D printers. They started with small variants, in 2014. Combining studying with working on customer projects, the duo decided to focus on B2B markets. “We kind of started as a two-headed design team,” Lucas explains. “Maarten is very much focused on engineering and developing breakthrough innovations that make things go faster or get stronger. I focus more on what the customer does with it, so I’m actually more on the customer side. What we both really have, though, is a love of design and technology. CEAD stands for Connecting Engineering And Design. We came up with that because Maarten studied mechanical engineering and I studied industrial design engineering,” Lucas explains.

When the two grow out of the garage box, they move to a workshop in an old power plant in neighboring Rotterdam. From there, the company grows by 10 people in a short time. CEAD thus quickly outgrows this location as well and fortunately returns home to Delft, at the Turbineweg. In 2018, the young company experiences another growth spurt and so CEAD enters its next phase. They get busier with more requests. So this year, they decide to look for another building with a bigger size again. They find it, at Schieweg 25. With a hall about four times the size of the old premises, they are ready to continue growing in the coming years.

For Lucas, the next phase means that the company will truly mature. Lucas explains what that means for CEAD: “We are now in the phase where we want to standardize more. When you’re a somewhat smaller company, you can have a much more personal approach. We want to keep that personal approach, but make it more efficient with standardization of machines. You have to think about making less customized products and offering more standard products. Above all, we want to do things more intelligently, so we want to look at the machines more from a modular point of view. Although a machine always looks different, it is actually built from the same modules.”

“We used examples to show what you can do with our machines. We have shown what is technically possible and we notice that now people decide much faster to actually purchase machines. They see the added value.”

This is not the only reason why the industry has since embraced 3D printing technology. The material CEAD’s machines print with is recyclable. “In terms of sustainability, it just has a lot more potential,” Lucas explains. “Our material is thermoplastic composite. It consists of plastic mixed with fibers. You can chop that up at the end of the product’s life, melt it and reuse it to print something else. Many other materials consist of hard composite. For example, airplane wings or wind turbine blades. You can’t recycle that, so you always have by-product at the end of the life of such a product.”

CEAD seems to have the wind in its sails, and it looks like it will stay that way for the foreseeable future. But with a club full of techies, relaxing is not an option. CEAD continues to develop new machines and even hopes to stop making only large 3D printers in the future. Not to retire, but out of love for the craft. “Our techies think it’s just cool when technology can do more and more,” Lucas explains. We therefore want to focus much more on what else is possible and actually become a complete production tool. We’ll still be making 3D printers, of course, but it will be a machine that can also do other things very well. For example, immediately apply a coating or extra reinforcement. Ultimately, we want the machines to become more and more efficient in the future. That you can make even more complex products. It won’t go so far that a car comes out of a factory in one go, but we can strive to have as many steps as possible already done.”