Threedy is a German high-tech start-up, spun-off from Fraunhofer IGD in late 2020. With instant3Dhub, Threedy offers a unique infrastructure component that allows companies to meet the constantly growing demand for highly available 3D data in responsive and interactive applications. Industrial 3D data can be referenced directly, e.g. from existing PDM or PLM systems, without prior preparation and can be automatically used for visualization, collaboration or mixed reality, linked with other business information. This results in new, scalable industrial 3D applications across the entire life cycle, from engineering to after sales – web-based and with zero-footprint on the client.

Interview with Christian Stein, CEO of Threedy.

Easy Engineering: What are the main areas of activity of the company?

Christian Stein: We consider ourselves as enabling technology for companies to cope the challenges of industrial 3D, Digital Twins and the Industrial Metaverse and giving them options to freely mesh and contextualize 3D data of any scale. Mainly customers from automotive, manufacturing, machine-building, aerospace or other heavy equipment companies utilize or software to enable use cases throughout the entire value chain, from engineering to after-sales and service. Current clients range from Mercedes-Benz and BMW to Innomotics (previous Siemens LDA), Trumpf or Électricité de France (EDF).

E.E: What’s the news about new products/services?

C.S: We launched just recently our “1-Click deployment” of instant3Dhub on the Microsoft Azure marketplace, further strengthening the ease-of-use of instant3Dhub. The integration into existing environments and seamless usage in i.e. Microsoft Teams is one of our biggest strengths. Our customer feedback is always valuable for us to improve our technology and services.

E.E: What are the ranges of products/services?

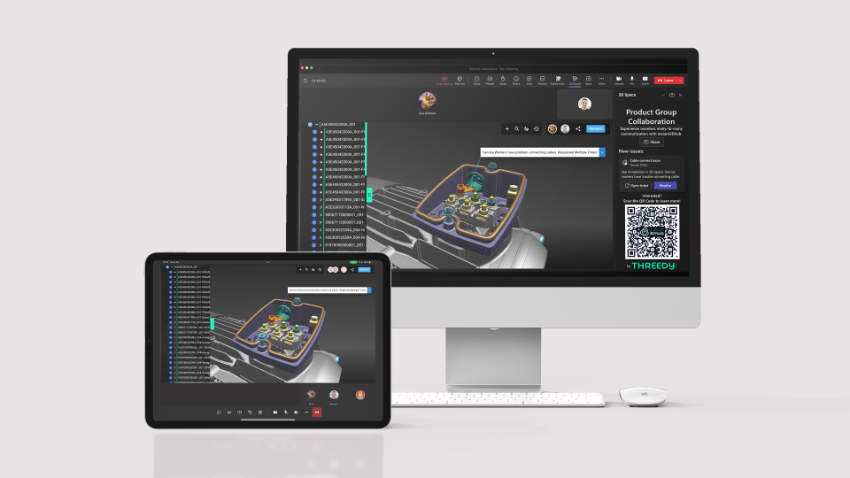

C.S: Everything revolves around our microservice infrastructure instant3Dhub. It is the central component to enable industrial 3D for various use-cases. Customer like Mercedes-Benz utilize instant3Dhub as a central backbone for enabling engineering-quality CAD data across the enterprise, e.g., enabling a wide range of Augmented Reality (AR) use-cases. BMW leverages the web-based nature of instant3Dhub to accelerate the entire engineering process with streamlined reviews and collaboration using our 3D Spaces, granting everybody instant access to data whenever needed, without pre-preparation, cloud upload or reduction of data quality.

E.E: What is the state of the market where you are currently active?

C.S: The market is always in motion. The current need of further digitalization, new work and the requests to improve the “Time-To-Market” give us often a good starting point with new clients. But we see also that the market has some challenging times ahead, resulting in tougher metrics to benchmark new and existing solutions. At the same time, mega trends like Digital Twins and the Industrial Metaverse accelerate further adoption of 3D and drive integration topics e.g., with IoT data.

E.E: What can you tell us about market trends?

C.S: We are seeing a lot of discussion about the potential value of AI in industry. These discussions go hand in hand with several initiatives around the Industrial Metaverse. Both initiatives focus on the complete digitalization of existing plants and machines and the further use of AI to facilitate knowledge. These trends match our vision for industrial 3D data, focusing on a holistic view of data and knowledge. A key differentiator is still the approach. We believe that monolithic platforms and centralized data will never bring the ultimate value for customers, but we need systems that embrace IT’s reality and are able to deal with a heterogenous landscape e.g., different data silos, a variety of formats and API-driven interconnectivity.

E.E: What are the most innovative products/services marketed?

C.S: We see instant3Dhub as a unique technology that is by design not split into different services or products. This gives our customers the freedom to grow with the technology (and complexity) as they go. They do not need to plan or know their “end game”, but iterate on a sustainable basis with a software that is as flexible as the customer needs and supports them in whatever direction the wan to create value around industrial 3D data visualization, collaboration and Mixed Reality.

E.E: What estimations do you have for 2024?

C.S: Strengthened by our latest financing round, we will be able to further build our team and reach the next level when it comes to accelerating topics like AI or general integrations with complementary software e.g., from our partners. At the same time, we are investing in our commercialization, focusing on customers from the DACH region. We are pleased with what we could achieve so far and the opportunities to take further major steps in 2024.