TM Robotics, a globally recognized distributor of Shibaura Machine robots, has installed numerous robots in factories across continents such as North and South America, Europe, the Middle East, Africa and Australia. In partnership with Shibaura Machine, TM Robotics offers a comprehensive range of robots across all three categories: 6-axis, SCARA, and Cartesian. These robots are meticulously designed and manufactured in-house by Shibaura Machine in Japan. Until 2020, Shibaura Machine was known as Toshiba Machine.

TM Robotics also specializes in delivering cutting-edge solutions, training programs including remote training and support services for industrial and commercial applications.

Interview with Nigel Smith, CEO of TM Robotics.

Easy Engineering: What are the main areas of activity for TM Robotics?

Nigel Smith: TM Robotics offers robotics solutions to a wide range of industries. Its areas of activity span multiple sectors including manufacturing, automotive, pharmaceuticals, food and beverage, electronics and more. With its extensive range of robots, TM Robotics caters to diverse applications such as assembly, material handling, inspection, and welding. Its comprehensive offerings and expertise enable it to address the specific needs of various industries, driving efficiency, productivity and competitiveness.

E.E: Can you tell us about the recent news regarding new products?

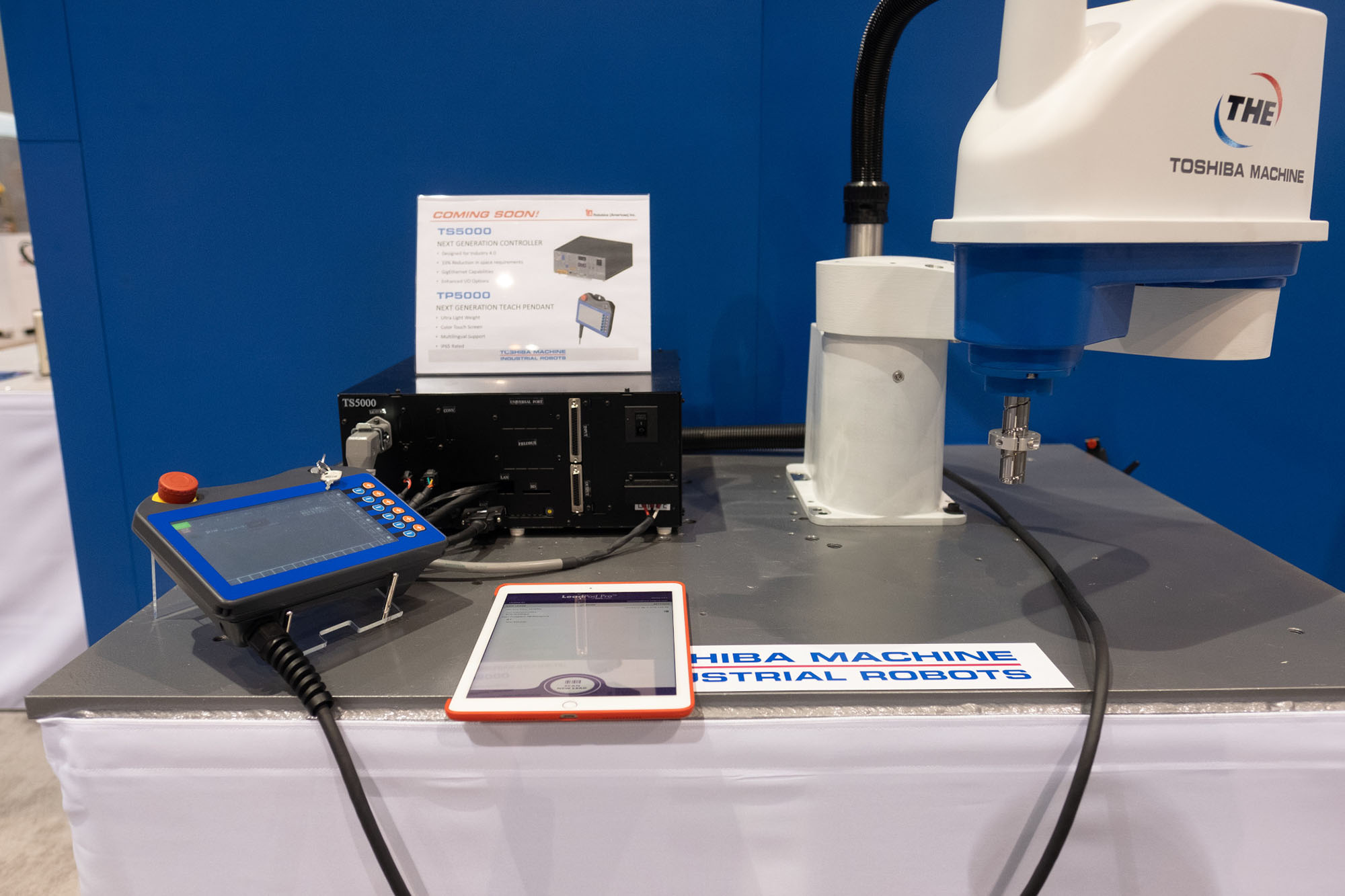

N.S: TM Robotics has introduced an expansive range of SCARA robots, known as THE, to the European market. This includes the recently launched THE800 and THE1000 models.

The THE800 boasts an arm length of 800 mm, ensuring precise and accurate movement trajectory along with high-speed operation. With a payload capacity of 20 kg, it is the second largest robot in the series and boasts a maximum cycle time of 0.41 seconds.

As the largest robot in the series, the THE1000 offers the same impressive payload capacity and is particularly suitable for processes that require extended reach, thanks to its one-meter arm length. Both new additions, like the entire THE range, are compatible with Shibaura Machine’s TS5000 controller, facilitating robot programming.

E.E: What are the ranges of products — and the most innovative — offered by TM Robotics?

N.S: In partnership with Shibaura Machine, TM Robotics provides a comprehensive range of 6-axis, SCARA, and Cartesian robots. TM Robotics’ in-house design and manufacturing ensure high-quality products tailored to meet specific industry requirements.

Its 6-axis range includes the TVL, TV, and TVM series, delivering outstanding performance in assembly, material handling, and welding applications. The SCARA range encompasses various models, including the latest additions such as the aforementioned THE800 and THE1000, designed to handle heavy payloads and larger components. Lastly, TM Robotics offers Cartesian robots known for their versatility and precision in industrial settings.

E.E: What market trends have you observed in the industry?

N.S: TM Robotics has noticed significant growth in the pharmaceutical sector, largely driven by the pandemic and supply chain expansion. The need for rapid testing of components like test tubes and medical vials has resulted in a ten-fold increase in production. To meet this demand, automation and injection molding using robots from the TVM range have become essential. These robots enable cost-effective and high-quality manufacturing of medical devices.

Furthermore, changing food traceability standards have created a demand for faster identification and removal of substandard food items. Industrial robots, alongside advanced vision inspection technologies like Shibaura Machine’s TSVision3D system, play a crucial role in swiftly eliminating contaminated foods from production lines.

E.E: What estimations do you have for 2023?

N.S: Looking ahead to 2023, TM Robotics anticipates a continuation of the rapid emergence and of collaborative robots witnessed in the past five to ten years. This expansion will extend to peripheral equipment, with increased focus on safety integration. Vision systems will play a vital role in enhancing safety measures by enabling robots to perceive their surroundings and differentiate objects accurately.

As artificial intelligence continues to advance, collaborative robots will possess an improved understanding of their environment, distinguishing between humans and other objects. The industry is also expected to develop standardized safety measures to ensure consistent and reliable practices across various applications and sectors.

Going forward, TM Robotics remains committed to delivering cutting-edge robotics solutions to various industries worldwide. With its comprehensive range of 6-axis, SCARA, and Cartesian robots, TM Robotics continues to push the boundaries of automation, enhancing efficiency, productivity, and safety in manufacturing processes.