TOffeeAM is a design software set to revolutionise R&D process – driven by physics simulation and powered by AI. The company cuts costs and time to market by automatically designing for better performance and efficiency.

Interview with Marco Pietropaoli, CEO of TOffeeAM.

Easy Engineering: A brief description of the company and its activities.

Marco Pietropaoli: TOffeeAM stands for Topology Optimisation For Fluids enginEEring for Advanced Manufacturing. Maybe people do not know that the first office of TOffeeAM was in a biscuit factory, we believe this inspired us for the name of the company.

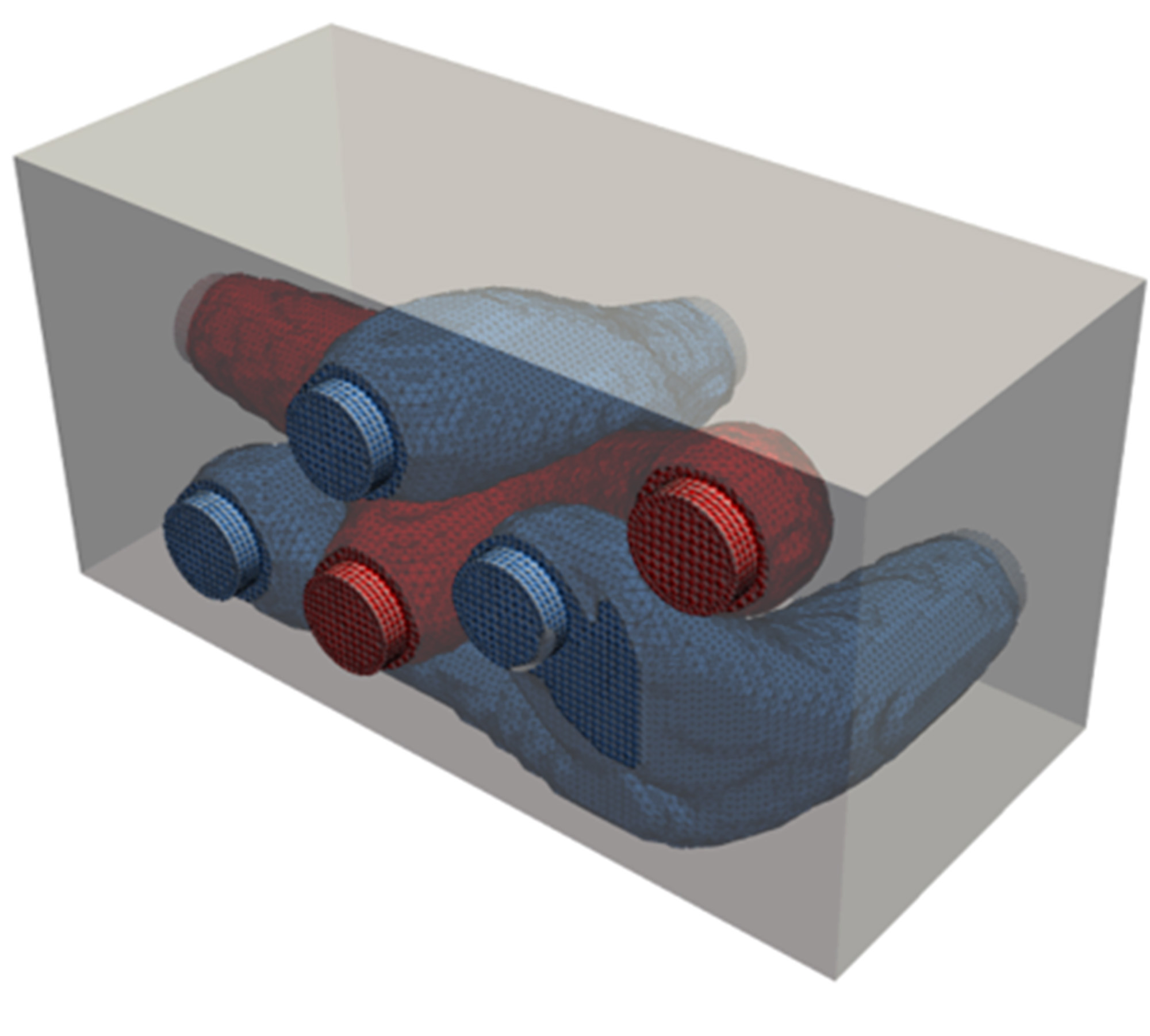

Our unique multi-physics, multi-objective software creates optimal designs in minutes or hours, not days or months.

All you need is a design space, the fluid and material properties, and the type of performance you want to optimise. The rest is automatic.

Started in 2019 as spinout of Imperial College London, today counts more than 25 engineers.

ToffeeAM’s AI software is used by some of the world’s leading engineering companies – including Boeing and Rolls-Royce.

It has a been tremendous journey so far to be at TOffeeAM, from initial investors that believed in our vision as founders, to nowadays where we have worldwide customers and a growing team, from aerospace, to automotive to software engineering. This has been possible thanks to our clients that helped us to improve, day after day, our solutions.”

Considering the challenges in front of us for NetZero, both in aerospace and automotive, you need design outside today experience: TOffeeAM will design for you unthinkable solutions that can shape the next generation of cars and planes.

E.E: What are the main areas of activity of the company?

M.P: Our software platform has found widespread applications across various industries, ranging from aerospace and automotive to energy sectors. Its remarkable adaptability has made it an invaluable tool for engineers and designers seeking innovative solutions for next generation products. While the software’s capabilities make additive manufacturing an enticing option, it is intriguing to note that the majority of customers continue to rely on conventional manufacturing methods.

In the aerospace industry, where precision and reliability are paramount, the software has revolutionized the design and development of complex components. Engineers can leverage its advanced features to optimize structural integrity, reduce weight, and enhance performance, all while adhering to stringent industry standards.

Similarly, in the automotive sector, the software has played a pivotal role in streamlining the design and production processes.

Furthermore, the software has made significant contributions to the energy industry, particularly in the development of advanced power generation systems and renewable energy technologies. Engineers harness its capabilities to optimize the design of turbines, generators, and other critical components, improving overall efficiency and performance.

E.E: What’s the news about new products?

M.P: Driven by our commitment to staying at the forefront of technological advancements, we continuously enhance our software by deploying new features every month. These updates are designed to accommodate a diverse range of physics, catering to industries as varied as rocket engines and bicycles.

For companies operating in sectors where innovation is fundamental to their core business, our software serves as a powerful tool. While it is versatile enough to be utilized by organizations of all sizes, it particularly caters to the needs of large enterprises.

E.E: What are the ranges of products?

M.P: Our software offers a comprehensive platform with versatile modules that can be utilized for designing a wide range of applications, from aircraft engines to CPU heat dissipators. Instead of requiring engineers to navigate between various software tools such as CAD, CFD/FEM solvers, and optimizers, our platform, TOffeeAM, provides a seamless solution. By logging into TOffeeAM, engineers can optimize their designs in a single streamlined process, eliminating the need for iterative workflows.

The benefits of using TOffeeAM are significant. For example, in a realistic case scenario, the design time has been reduced by a remarkable 20-fold. Additionally, the performance of the designs has been enhanced by a factor of 3, resulting in improved efficiency and functionality. Notably, the environmental, social, and governance (ESG) impact has been significantly reduced by more than 90%, highlighting the software’s potential in promoting sustainable engineering practices.

Whether it involves the thermal management design of aircrafts or the development of cutting-edge battery systems, TOffeeAM empowers engineers to optimize their designs efficiently and effectively. By providing a unified platform that integrates multiple design and optimization tools, our software streamlines the engineering process, enabling engineers to achieve superior results in a fraction of the time compared to traditional methods.

E.E: At what stage is the market where you are currently active?

M.P: Our platform has gained global recognition and is widely adopted by numerous companies across different regions, including the US, EU, UK, and Japan. As the advanced manufacturing and software markets continue to experience exponential growth, we find ourselves at an exhilarating juncture in our company’s journey.

The increasing demand for advanced manufacturing solutions and software underscores the significance of our platform in meeting the evolving needs of industries worldwide. This momentum propels us forward, energizing our team and driving our commitment to innovation and excellence.

The convergence of these expanding markets presents a multitude of opportunities for our company. We are excited to be at the forefront of this transformative era, working hand in hand with our customers to navigate the complexities of advanced manufacturing and leverage the power of our software platform to unlock new possibilities.

E.E: What estimations do you have for 2023?

M.P: 2023 just started and we have been taking part to many events from TCT in Japan, to Paris Air Show in June. We found a lot of interest and more and more customers willing to change their design system to something more advanced, allowing better performance, in reduced time and with greener impact.

At the same time, we are hiring new talents and we are always looking for the best software engineers around the world.