uviblox develops, builds and installs exhaust air purification systems for the treatment of polluted waste air from industrial processes as well as from municipal sewage treatment plants and wastewater systems.

The company is characterized by the combination of innovative UV technologies for foto-oxidation (uviblox FOX) with classic catalytic oxidation processes (uviblox CatOx) and activated carbon filters (AC). This enables them to provide customers with tailor made solutions for the energy-efficient and cost-effective removal of volatile organic compounds (VOCs) and odors (e.g. H2S) from exhaust air streams.

Interview with Johannes Münz, Sales Engineer KF-Group at uviblox GmbH & Harbauer Kenya.

Easy Engineering: What are the company’s main areas of activity?

Johannes Münz: Our customers include industrial companies from the food & beverage sector, chemical and petrochemical industries as well as paint and solvent processing companies from the surface finishing and automotive sectors. While the private sector often focuses on reducing volatile organic compounds (VOC) such as solvents, municipal wastewater treatment plant operators are primarily concerned with eliminating odor.

E.E.: What advantages do customers gain from using your technology?

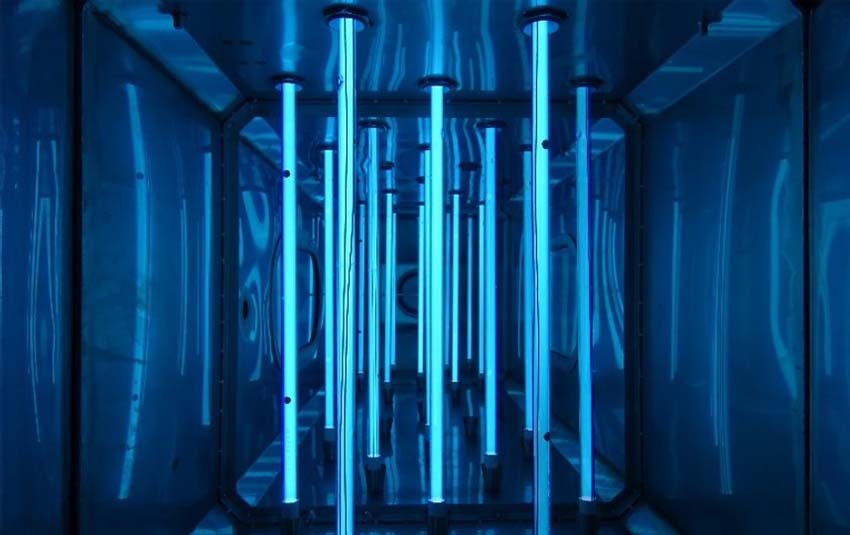

J.M: Our innovative foto-oxidation process (uviblox FOX) is significantly more compact and cost-effective to operate than conventional processes such as biofilters. In addition, unlike biological processes, it is independent of the weather and ambient temperature. With the UV-technology we can also react much more dynamically to fluctuations in the volume flow (m³/h) and pollutant concentrations with FOX systems than is the case when using microorganisms to purify waste air. These were among the reasons why the “Abwasserkanal Emscher” (AKE), one of the biggest sewer systems in Europe, was equipped with a total of 33 of our UV systems instead of biofilters.

The foto-oxidation systems realize the forced ventilation of the “generation project” on “Abwasserkanal Emscher” and thus protect the concrete sewer from corrosion. After all, the AKE is expected to last for at least 100 years. The hydrogen sulfide (H2S) and other odorous substances typical of wastewater that are extracted during forced ventilation are oxidized and broken down by irradiation with UV-C light and the formation of ozone (O3) and hydroxyl radicals (OH*). This prevents the emission of H2S and protects the population in the Emscher region from unpleasant odors. The municipal water treatment company “Stadtentwässerungsbetriebe Köln” also decided to install two of our UV systems for odor elimination at the “Stammheim” wastewater treatment plant in 2023.

E.E: What other technologies do you offer for waste air purification?

J.M: In comparison to municipal water suppliers in the industry, it is more about avoiding solvent emissions and complying with the limit values according to local guidelines like TA-Luft in Germany. In 2023, for example, uviblox installed a system with two adsorption wheels and a downstream uviblox CatOx at a customer in the aviation industry to remove solvents from a production process from an exhaust air flow. The adsorption wheels lead to a concentration of the solvents (VOC), which means that autothermal operation of the CatOx can be realized. This means that no additional fuel needs to be added to the system to reach the 400 – 600°C required to break down the pollutants. This not only saves CO2 emissions, but also saves our customers money. In this way, we achieve very short amortization times and our customers benefit quickly from their investment in our modern system technology.

E.E: At what stage is the market in which you are currently active?

J.M: Due to the carbon dioxide pricing introduced by the German government in 2021, we are receiving an increasing number of enquiries from industry looking for energy-efficient alternatives to conventional thermal post-combustion and RTO systems. These processes often must be fueled with natural gas or other fossil fuels in order to achieve the needed temperatures. In the case of painting work, more and more suppliers are switching to water-based paints, which reduces the solvent content in the exhaust air. That sounds good for the environment at first. With RTO-based exhaust air purification systems, however, this can lead to even more gas having to be added. With the sharp rise in energy prices in the past combined with increasing CO2 taxes, operating such a system can become very expensive.

With UV technology, the use of adsorption wheels and energy-efficient CatOx systems, uviblox offers environmentally friendly alternatives with significantly lower operating costs.

E.E: What are your expectations for 2024?

J.M: Next year, we will once again be installing several UV systems for odor elimination at municipal wastewater treatment plants and in the industry. The order books for 2024 are already well filled.

I am particularly looking forward to a pilot test with an interested party to remove siloxanes from production exhaust air. These substances can lead to the formation of glass-like deposits in downstream plant components and thus cause major damage. In collaboration with one of our many partners, we are investigating a special pre-cleaning process in order to clean the conditioned waste air in a downstream catalytic oxidation process in autothermal operation and help our customer to comply with the limit values of TA Luft.

In addition to the planning, construction and delivery of exhaust air purification systems, we also offer measurement campaigns for examining the current status and pilot tests for the conceptual design of exhaust air purification systems.