WAFIOS is a mechanical engineering company that has been active in the wire and tube-processing industry for more than 130 years. The WAFIOS name is synonymous with outstanding quality, safety standards, and technical innovations in the German mechanical engineering industry.

The WAFIOS Group is made up of multiple subsidiaries, including WAFIOS Umformtechnik, WAFIOS Tube Automation and E. W. Menn. Through its worldwide presence, the WAFIOS Group has locations in the USA, France, Portugal, Mexico, Brazil, China, and more.

Interview with Dr. Thomas Kaup, Senior Executive Vice President Sales at WAFIOS.

Easy Engineering: What are the main areas of activity of the company?

Thomas Kaup: We develop, design, and produce sophisticated, specialist machinery for the wire and tube-processing industry and for cold-forging applications. Equipped with the latest software, artificial intelligence, and IoT, WAFIOS machines not only optimize output and quality, but also make the setup process easier.

A large proportion of our customers work in the automotive and supplier industry, and we have a growing share in e-mobility. But we also serve major industries such as mining, construction, electrical engineering, medical technology, household appliances, agriculture, and furniture. Exports account for more than 60 percent of total sales.

E.E: What’s the news about new products/services?

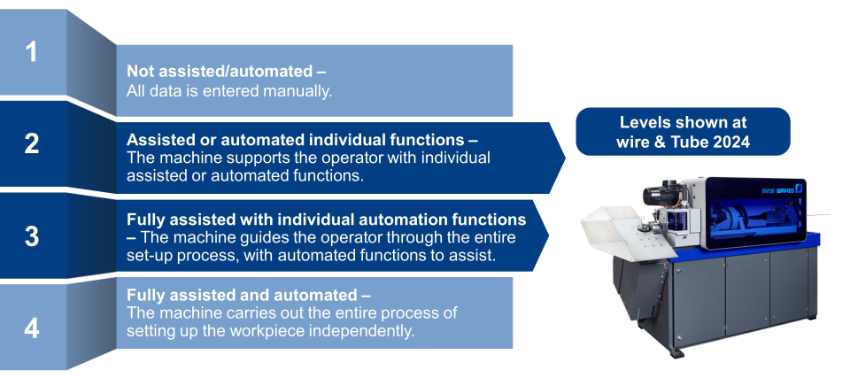

T.K: State-of-the-art machines deliver complex production tasks with outstanding performance. Given the current lack of specialists available to run them, however, they frequently see changes in operators. Here at WAFIOS, we asked what we could do to give new employees a quick, reliable way of getting to grips with machinery. The result is semi-assisted and fully assisted machines that support operators in carrying out certain tasks or guide them through the entire setup process.

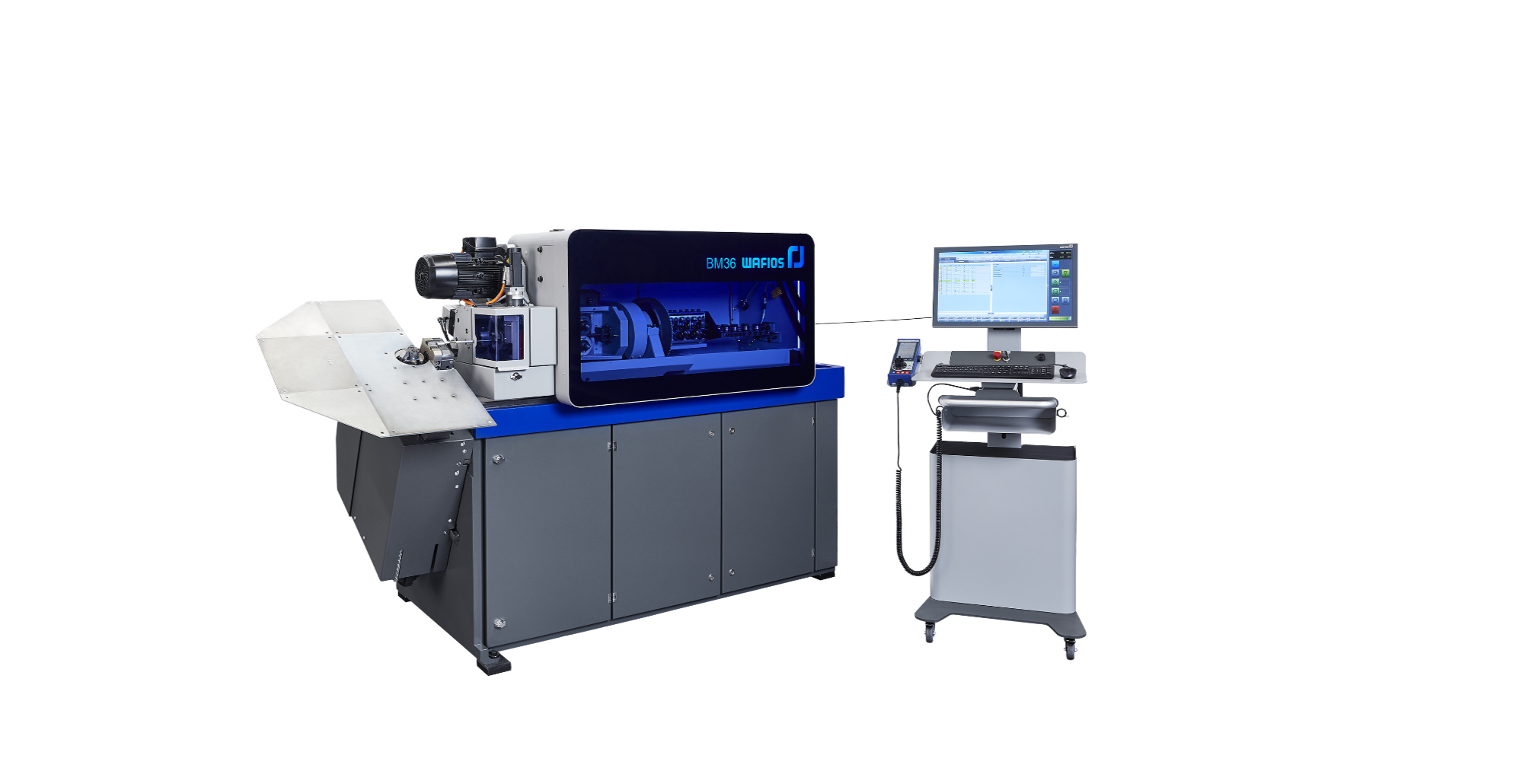

As expected, this year we will once again be launching new machines for the wire and tube industry. This includes an addition to our world-renowned FMU range, for example, with the FMU 100+ universal torsion spring machine that extends the operating range to wire diameters measuring up to 10 mm. Meanwhile, the BQ 10 is being added to our bending equipment: A modular machine that makes production flexible, its bending, flattening, die-cutting, and forming stations can be arranged to suit individual needs.

E.E: What are the ranges of products/services?

T.K: We offer a highly versatile product range that is designed to equip the wire and tube-processing industry with machines that can handle everything from straightening and bending to forming.

We also provide an extensive range of service-based solutions. Thanks to our modern spare parts storage concept and our close collaboration with logistics service providers, spare parts can be delivered in next to no time. Of course, our employees are also available to attend customer sites if maintenance or repair work is needed.

Sustainability is a subject that is close to our hearts. Our retrofit options are designed to appeal to customers who want an inexpensive, resource-friendly alternative to buying a new machine. They involve giving old machines a full overhaul in order to bring them in line with the latest standards – a process that also extends their service life.

E.E: What is the state of the market where you are currently active?

T.K: For many years, our main sales market was in the automotive industry, where we focused particularly on combustion engines. As the industry has shifted in favor of electromobility, however, our market has changed along with it. Electric cars simply do not need many of the components that are used in vehicles with combustion engines. In response to this development, we now offer machines that are specifically tailored to e-mobility requirements. The SpeedFormer enables series production of hairpins, for example, while the BMF range can be used to produce high-quality busbars. In addition, we offer solutions for new types of motor technology and for axial flux motors.

E.E: What can you tell us about market trends?

T.K: As mentioned, electromobility is increasing in popularity and represents a growing proportion of our sales.

E.E: What are the most innovative products/services marketed?

T.K: One of our biggest innovations has to be the semi-assisted and fully assisted machines that guide operators through the setup process. They not only make tasks quicker and easier, but also contain functions that ensure high standards of quality and result in less waste, reducing material costs.

WAFIOS offers innovative solutions in the field of tube processing too. Marking a first, the TWISTER² 35 provides a CNC-controlled tube gripper device with rotary unit, which creates more flexibility and enables quick positioning for the bending process. The machine also features an integration bending tool for simultaneous processing of three different tube diameters – ideal for the hydraulic industry, for example. This means that the machine can process components with different outer diameters without the need for tool changes.

E.E: What estimations do you have for the beginning of 2024?

T.K: In the wire industry, steel is currently experiencing less dynamic growth than copper in the cable sector – but there are still some areas that are performing well. At the same time, we are of course continuing to maintain a strong position in our traditional market. Wire and Tube, the world’s largest trade fair in its sector, offers the perfect global platform for networking and presenting cutting-edge products for highly innovative applications.

Romanian representative: Wire & Cable

Bv.Pipera, nr.1, bl. 5, apt.10, Voluntari, ROMANIA

mihai.frangulea@wireandcable.ro

+40 756 542 955 , +40 744 568 058