1,000 possible robotic arm/extruder configurations, multi-material extrusion with pigment control, and customized serial production.

Since 2012, WASP has contributed to the opening of new frontiers in the world of digital manufacturing, moving simultaneously on several technological fronts. From the world of ceramic and architectural 3D printing, establishing itself as a forerunner in the field, to thermoplastics, with a focus on pellets and recyclates, WASP has always put three key concepts first: sustainability, innovation, and accessibility.

This year, WASP is presenting at Formnext 2023 a series of unprecedented technological innovations in the world of LDM (Liquid Deposition Modelling) and FGF (Fused Granulate Fabrication) 3D printing.

Among the new products presented: CEREBRO, METAMORFOSI, and WASP App.

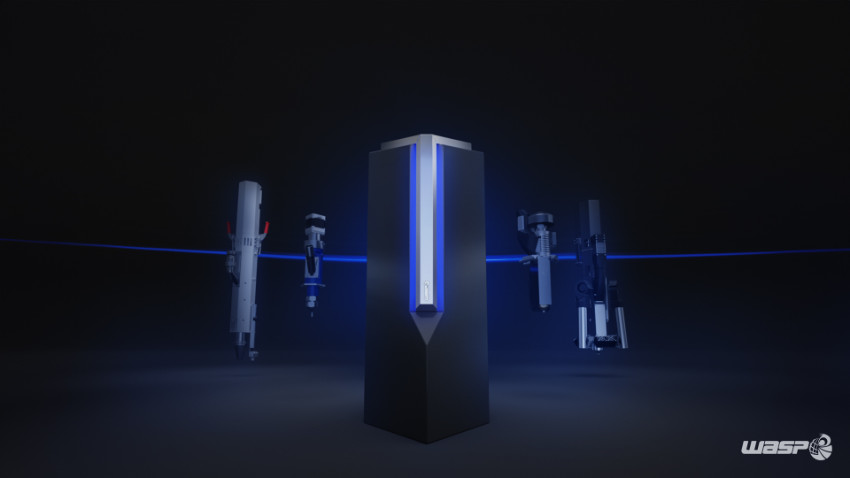

CEREBRO: the integration system between robotic arms and WASP extruders

The two technological frontiers pursued by WASP since its start are meeting in a new product that opens the way to the world of robots: CEREBRO, an integration system between robotic arms and WASP extruders, both LDM and FGF.

CEREBRO is a state-of-the-art system that allows robotic arms to be transformed into a 3D printer. Compliant to Industry 4.0 technology, it can collaborate with multiple of WASP’s patented systems, controlling both extruders and printing tools simultaneously.

It allows more than a thousand combinations between robots and WASP extrusion technologies, including our patented FIRECAP localized heated chamber and Vacuum Buildplate System, which allows the use of different types of printing planes that are compatible with the material being used, guaranteeing excellent adhesion.

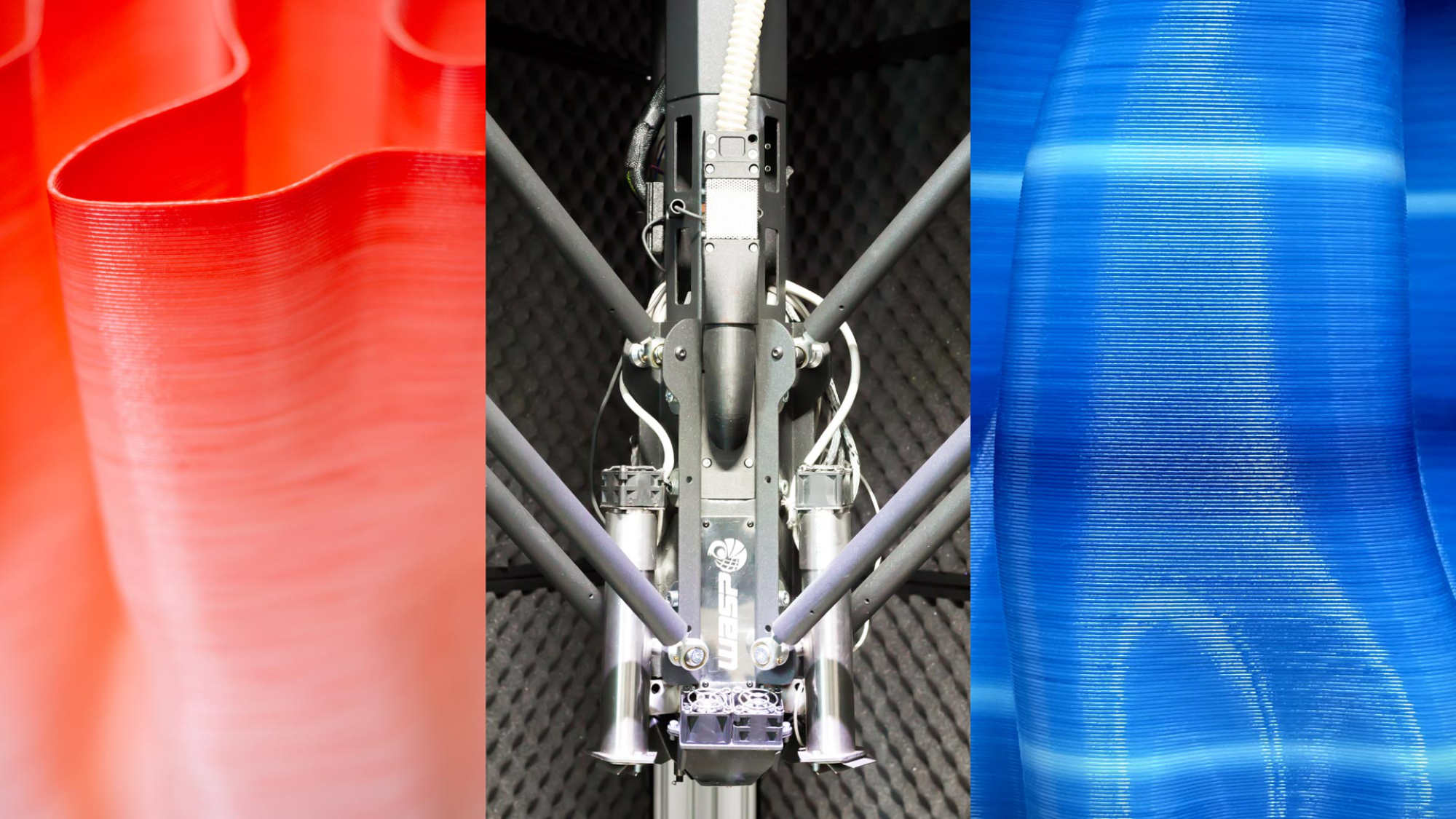

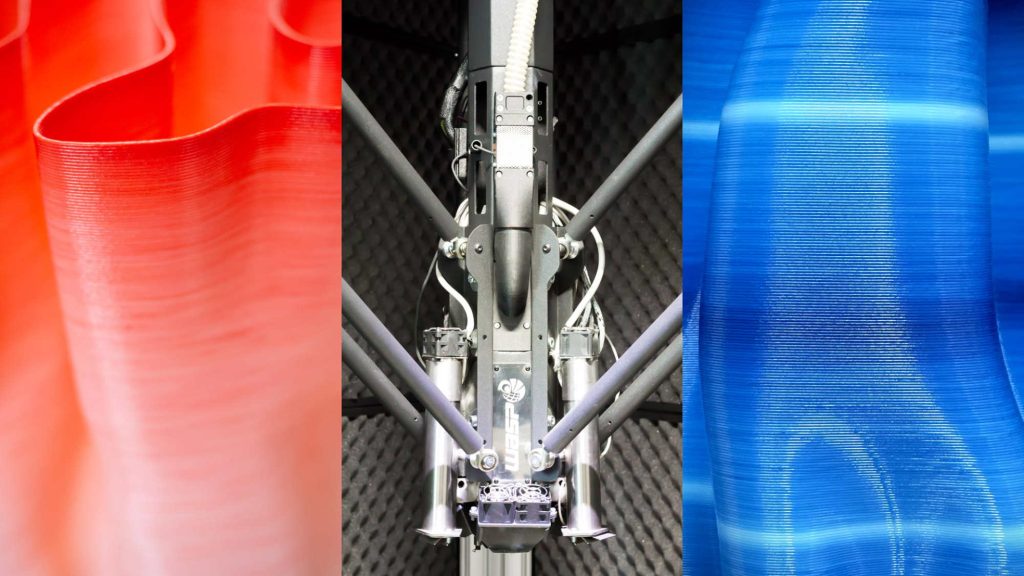

METAMORFOSI: the new multimaterial pellet extrusion system

Over 8 years ago, WASP had already recognized the significant potential of pellet 3D printing, successfully creating the first large-scale pellet 3D printer.

All the knowledge acquired over years of work and continuous improvements has led to the development of the most advanced line of pellet 3D printers to date: WASP HDP (High Definition Pellet).

Today, WASP presents METAMORFOSI: the new patent-pending pellet extrusion system that can control and modify the position, quantity, and properties of the material at different points in the printing process.

This paves the way for a new dimension in 3D printing, making it multi-material by incorporating fibers or different materials during the printing process, altering their characteristics to make the material stiffer in some areas and more flexible in others.