Modern industrial conveyor technology deploys numerous advanced technologies that help companies automate their production and increase the efficiency of their processes. One of these technologies is vision systems, which can capture, analyze, and interpret visual information from machines and their surroundings. Combined with high-quality belt conveyors and aluminum framing systems, companies can benefit from these systems’ numerous advantages.

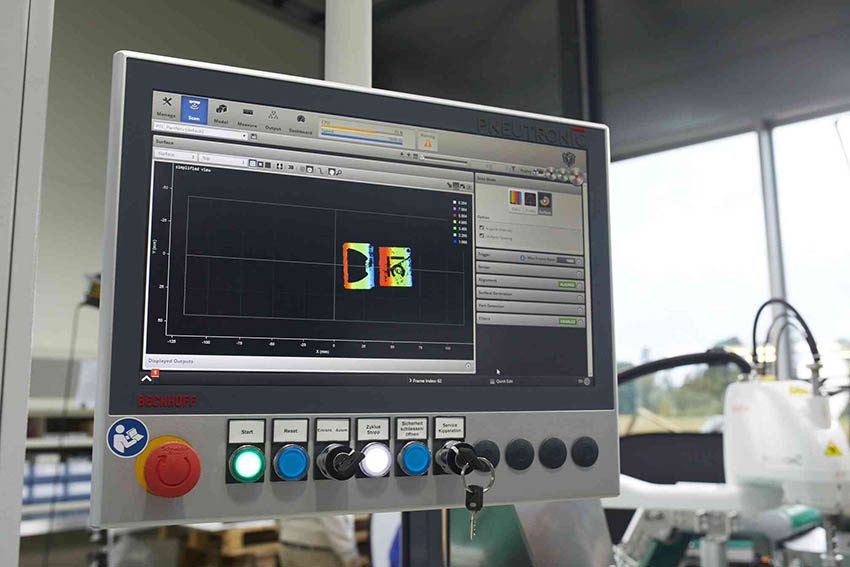

Vision systems in conveyor technology are automated systems that use optical technologies to inspect products and materials and detect defects or irregularities. These systems use cameras to capture images of products or materials and evaluate those images using algorithms to identify defects or deviations from specific standards. This enables companies to produce better-quality products and become more efficient, since they can detect and sort out defective products at an early stage.

The many benefits of vision systems

Vision systems offer many advantages when used with conveyor technology. For example, they enable automated inspection and detection of defects in products, such as cracks, scratches, or discoloration. They can also identify and sort products to prevent packaging errors. In conveying processes, vision systems can accurately measure product dimensions and control the positioning of products on a belt. Vision systems’ automation of processing and rapid product quality decisions can help improve product quality and increase production efficiency by sorting out defective products and preventing them from going on the market. Vision systems can also provide real-time data to optimize production processes, such as controlling material flow and production speed.

The right hardware is critical

Several important factors are required to take advantage of the many benefits that vision systems offer. These include clear requirements, effective software, experienced professionals, and regular maintenance and training. In addition, high-quality hardware is critical to ensure accurate and reliable system performance. Such hardware includes high-resolution cameras, constant brightness lighting systems, powerful computers and processors, as well as sturdy belt conveyors and aluminum framing systems.

Flexible and precise solutions

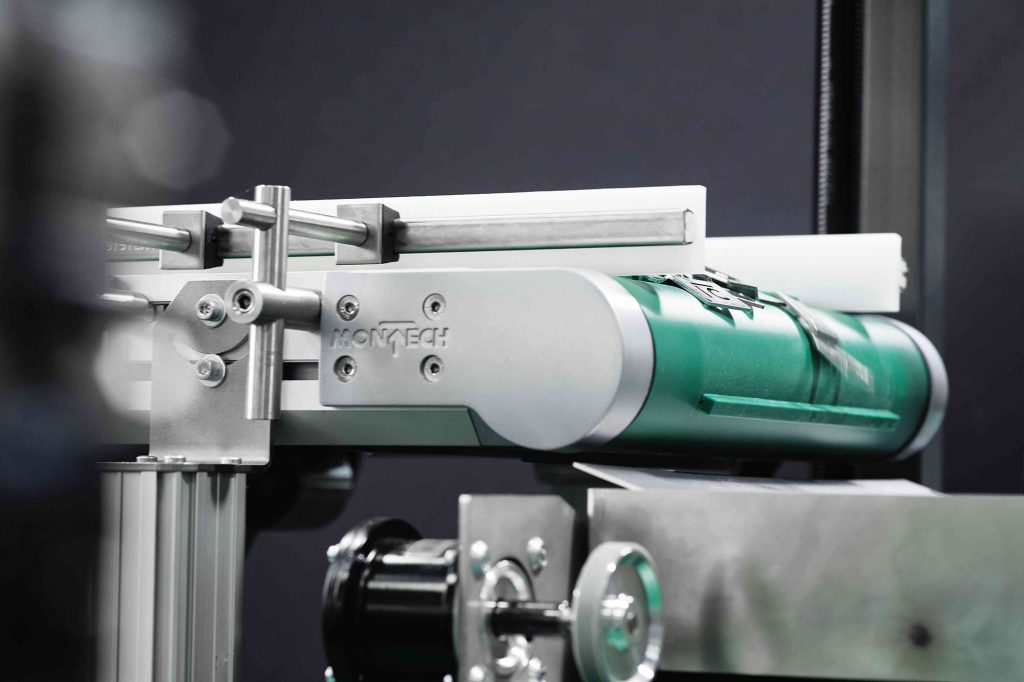

Montech AG offers the perfect solution for the seamless integration of vision systems into a conveyor system. This Swiss company specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. Its high-quality belt conveyors and aluminum framing systems are known for their precision and reliability. Its flexible conveyor systems allow precise and rigid mounting of vision systems without sacrificing flexibility. The TB40 belt conveyor, for example, can allow products to pass through the image processing system, allow them to pass through and return to a specific location, or it can stop products precisely at a desired location. Regardless of the industry, whether food or pharmaceuticals, Montech AG offers tailor-made solutions and assists its customers even beyond sales.