Xact Metal is a pioneering force in the field of metal 3D printing, founded in 2019 with a clear vision- to make additive manufacturing accessible to small and medium companies. The company is dedicated to providing high performing, user-friendly, cost-effective, solutions that empower businesses to transform their manufacturing processes. The team, comprised of individuals with diverse backgrounds, brings a wealth of experience in both traditional and additive manufacturing.

Xact Metal gos to market through their 25+ sales partners to provide installations and service locally to customers around the world.

Interview with Abigail Nelson, Marketing Communications Manager at Xact Metal.

Easy Engineering: What are the main areas of activity of the company?

Abigail Nelson: Our primary focus lies in the design and manufacturing of powder bed fusion metal 3D printers. We aim to address the challenges faced by manufacturers, offering solutions that enhance flexibility, reduce costs, and promote design innovation. Xact Metal’s activities revolve around the development, production, and support of our metal 3D printers.

E.E: What’s the news about new products?

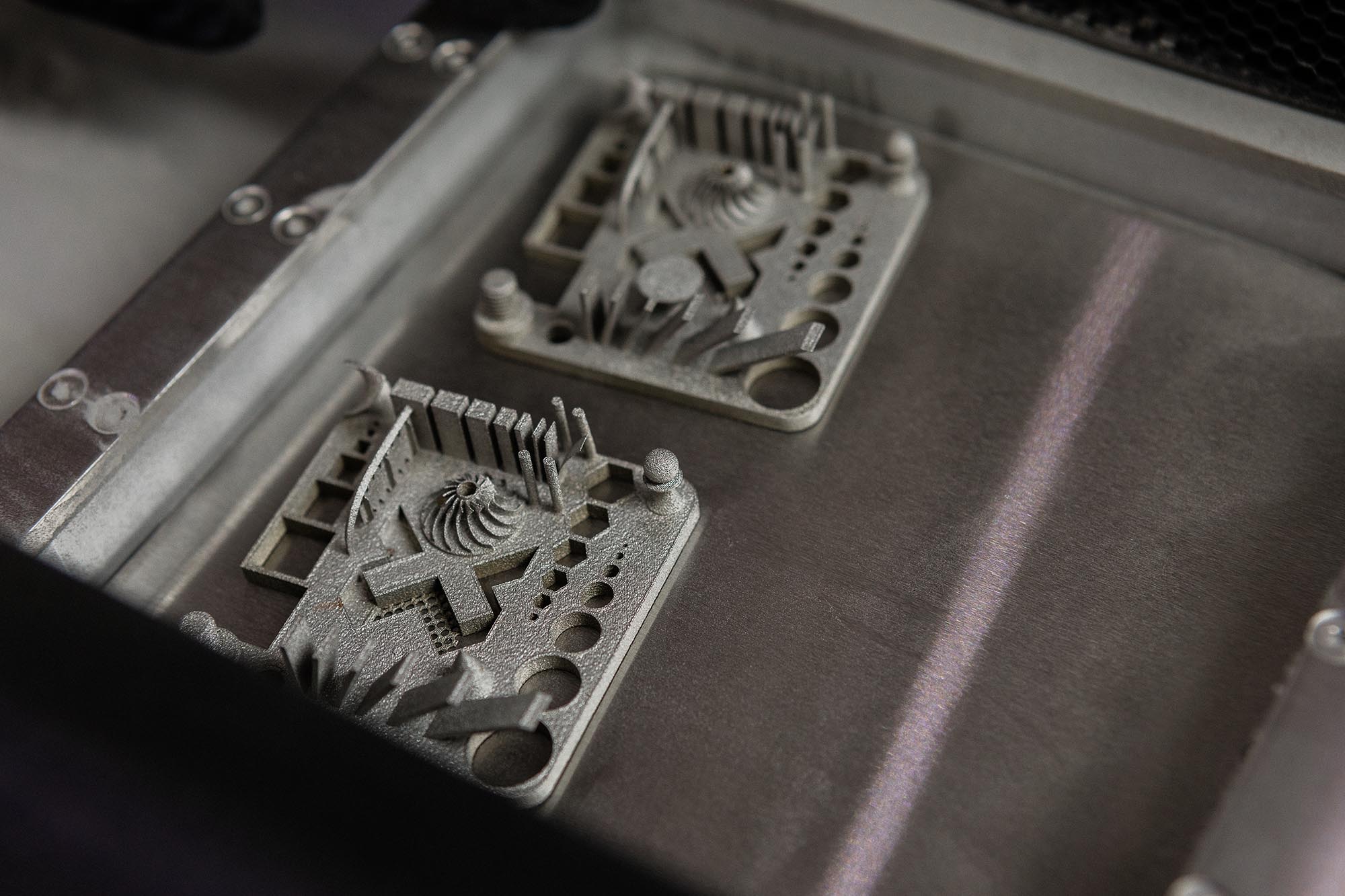

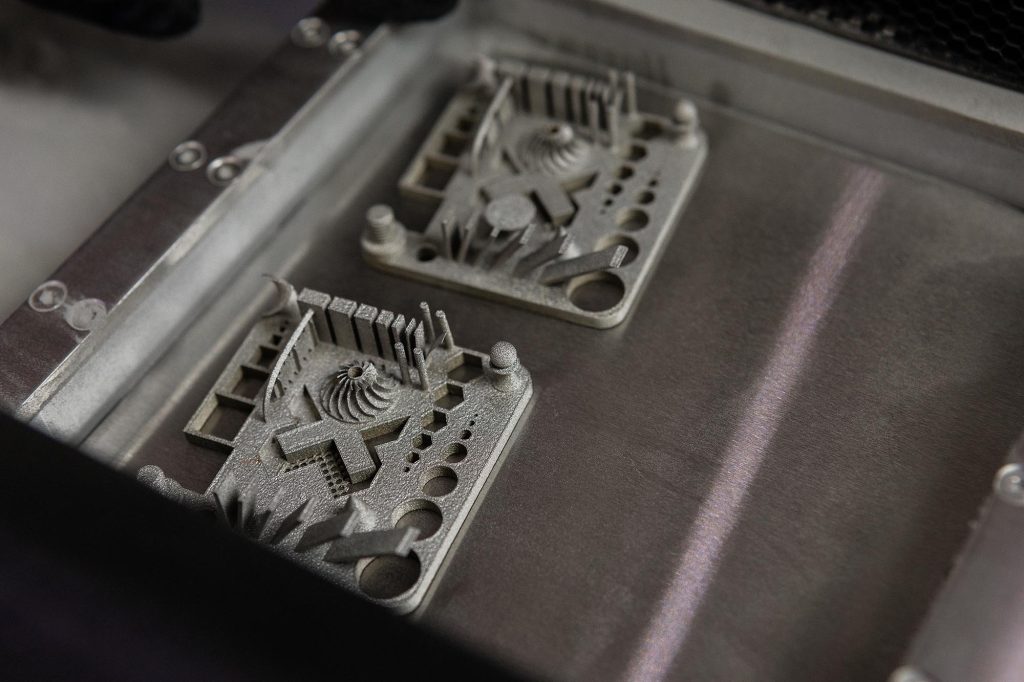

A.N: In 2021, we launched the XM200G, a metal 3D printer that incorporates over 20 printed components produced in-house. This not only showcases our commitment to innovation for small-medium sized companies, but it also allows us to pass significant cost savings to our customers. We also have a larger unit, the XM300G, in development which will be geared towards larger parts and production style printing.

E.E: What are the ranges of products?

A.N: Our flagship product is the XM200G, a reactive-capable, dual-laser powder bed fusion 3D printer. This printer comes with customizable specifications, such as printer wattage, laser count, and micron spot size, providing our customers with flexibility tailored to their specific needs.

Our first printer was the XM200C. This printer operates on an XY gantry system opposed to the galvanometer mirrors in the XM200G. With a slightly smaller build volume compared to the XM200G and considerably less speed, this unit is perfect for those who are just entering the additive manufacturing space and are looking for a low commitment to begin with.

E.E: At what stage is the market where you are currently active?

A.N: Currently, we are actively engaged in dynamic market where the demand for metal 3D printing technology is rapidly growing. Our focus is on serving small and medium manufacturers who seek to leverage the benefits of additive manufacturing without the traditional barriers of high costs and limited design flexibility. Our printers are capable of printing in many materials, which allows us to participate in multiple industries, each at a different stage in the adoption cycle of additive manufacturing technology.

E.E: What can you tell us about market trends?

A.N: The metal 3D printing market is currently undergoing dynamic shifts, driven by a surge in demand across industries such as aerospace, automotive, and healthcare. There is a noticeable trend toward the adoption of additive manufacturing solutions, particularly in sectors requiring intricate, low-volume components, such as the tooling industry. Key drivers influencing these trends include a growing emphasis on customization, a drive for cost-efficiency, and an increased focus on sustainable manufacturing practices. As we move forward, these trends are shaping the landscape of metal 3D printing, presenting opportunities for innovation and collaboration.

E.E: What are the most innovative products marketed?

A.N: Our most innovative product is undoubtedly the XM200G, supported by the internal manufacturing economy at the Xact Metal office and offering multiple options for customers specific needs. By producing printers that contribute to building more printers, we’ve achieved a level of cost-effectiveness and customization unparalleled in the industry.

E.E: What estimations do you have for the rest of 2023?

A.N: Looking ahead, we anticipate continued growth and impact throughout 2023. Our focus remains on expanding accessibility to metal 3D printing technology, fostering partnerships, and staying at the forefront of innovation. We are optimistic about the positive transformations our technology can bring to manufacturers across various industries.