CASE Construction Equipment has received the prestigious Good Design® Award for its methane-powered wheel loader concept from the Chicago Athenaeum: Museum of Architecture and Design and The European Centre for Architecture Art Design and Urban Studies

CASE Construction Equipment received the prestigious Good Design® Award for ProjectTETRA, the methane-powered wheel loader concept that provides an insight into a sustainable, connected and technologically advanced future of construction.

The Good Design® program is the oldest design awards programme, organised by The Chicago Athenaeum: Museum of Architecture and Design in cooperation with The European Centre for Architecture Art Design and Urban Studies, and recognises the best designed products across the globe for sustainability, superior design and unparalleled function.

The jury of the 69th Good Design program, composed of renowned international specialists with broad design experience, selected this year’s winners following the original program’s criteria, which include the innovation, functional and ecological impact of each winning product. As a winner of the award, ProjectTETRA will be featured in the Good Design Yearbook for 2019-2020 and can be viewed at the Museum’s website at https://www.good-designawards.com/.

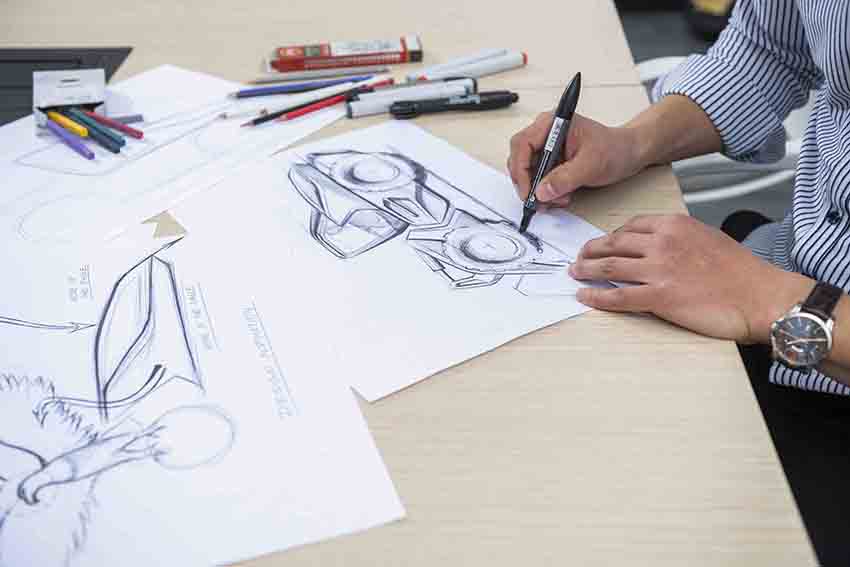

The CASE wheel loader concept, jointly developed by the CASE engineering and CNH Industrial international design teams, reimagines wheel loader design. It demonstrates the viability of alternative fuels in construction equipment and the feasibility of using fuel generated from waste products and renewable sources. It is powered by a proven methane engine, produced by CASE’s sister brand FPT Industrial, that delivers the same performance as its diesel equivalent. The innovative design includes cutting-edge styling and an advanced operator environment that makes extensive use of touchscreen and voice control technologies. The concept also offers innovative safety features that use biometric technologies and an obstacle detection system derived from CNH Industrial’s autonomous vehicle research and development programme.

ProjectTETRA has been tested in real-world construction environments, demonstrating its feasibility and proving its business case in terms of sustainability, reduced overall Total Cost of Ownership and operational viability.

For further information on ProjectTETRA, including images, video and technical information, please visit: http://bit.ly/CASE_ProjectTETRA.