CDR is a small family Italian company with 30 years of experience in research and innovation. It was set-up in 1990 when a group of professionals with a consolidated experience decided to merge into CDR the skills they had developed while working at relevant projects with leading Italian and foreign companies.

The skills acquired in the most diverse fields – ranging from mechanical and micro-mechanical engineering to photometry, biochemistry, electronic engineering and software development – represent the foundations of CDR’s capacity to fully leverage its “problem solving” skills on behalf of customers, which substantially means identifying the needs of potential customers in order to develop, define and design fully customized solutions.

Interview with Simone Bellassai, Division Manager at CDR FoodLab.

Easy Engineering: What are the main areas of activity of the company?

Simone Bellassai: Nowadays CDR is basically involved in the following sectors:

Food&beverage diagnostics. In this sector CDR produces specific analytical systems composed by an analyzer that works with dedicated reagents specifically designed for different kind of food matrices such as oils&fats, milk and dairy products, tomato sauces, egg products and bakery products or drinks like wine, beer, cider and kombucha. In the Food&Beverage analysis sector CDR has thousands of customers worldwide in the most diverse sectors, from the very small company to the big international corporations. The quality control systems produced by CDR are intensively used both in the quality control laboratory and over the production line, giving to the user the possibility to have quality control results in real-time.

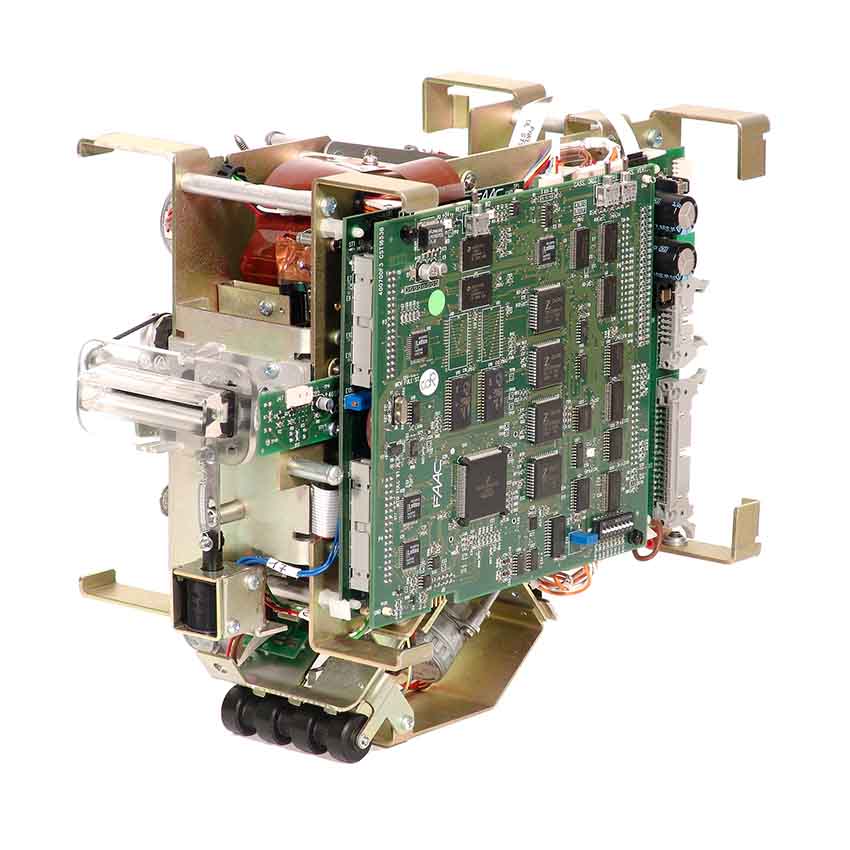

Telematics in which CDR supplies the most important Italian companies that manage the motorways in Italy. In this sector, the company produces automatic tolls mounted into the gateways, to enter in the motorways and to exit paying by credit card.

Sensoristics. In this sector, CDR develops and produce specific probes mounted on coffee machines, to detect the conductivity and the hardness of water. Our company is working to extend the probe production to other analytes as well. In this sector CDR is also deeply involved in the development of different kinds of sensors for the galvanic sector – whose one of the main applications is the supplying of accessories for the fashion and luxury industry – for the on-line determination of temperature, conductivity, Total Organic Carbon (TOC) and pH, in order to allow the galvanic industry to better manage its processes of degreasing, pickleing, galvanizing, burnishing and flushing.

E.E: What’s the news about new products?

S.B: Within the CDR Food&Beverage sector, CDR has just launched on the market the CDR CoffeLab, the new system to analyze coffee. It is an innovative system, derived from the CDR WineLab®, that will help the farmers to realize the quality control of their coffee fermentation, the roasters to better control the roasting process, till the coffee machine manufacturers that will be able to improve their R&D for a better espresso or a better brew extraction.

E.E: What are the ranges of products?

S.B: CDR produces systems in the sectors of Food&Beverage diagnostics, telematics, and sensoritics.

As already mentioned, in the telematic sector CDR is one of the “historical” suppliers of the main companies that manage the motorways in Italy, producing automatic toll collection terminals, and it is also deeply involved in the maintenance and in the continuous improvement of the related products in collaboration with the same customers, while in the sensoristics sector, CDR produces specific probes for the determination of conductivity and hardness in the water of the coffee machines, in order to optimize the management of the water to improve the quality of the extraction and the espresso coffee as well.

With respect to the Food&Beverage sector, CDR produces a range of analytical systems based on photometrical technology that use LEDs as wavelength sources. These analyzers use dedicated pre-filled and already calibrated reagents. The chemical pathway of the reagents depends on the specific parameter and it is based on enzymatic or chemical reactions. This particular combination between a specific analyzer and a dedicated reagent, joint with the optimization of the method, allows the CDR system to give reliable results with a high level of accuracy and precision. Thanks to these features the CDR analyzers are intensively used by a wide range of different customers that are involved in the Food&Beverage industry.

Within the CDR FOODLAB® line you can find CDR FoodLab®, able to analyze vegetable oils and animal fats, milk and dairy products, vegetable purees, egg products and bakery products, CDR PalmoiTester to analyze palm oil, CDR OxiTester to analyze olive oil and CDR BeerLab®, CDR WineLab®, CDR CiderLab, CDR KombuchaLab that allow the analysis respectively of beer, wine, cider, and kombucha. The main features of all the CDR systems are the reduction of the analysis time, the easiness of use, the ready to use and the pre-calibration of the reagents, the very low maintenance due to the robustness of the systems and last, but not the least, the fact that all these systems can be used by personnel without any technical background. All these features allow the CDR analyzers to be used both in the QC laboratories and along the production line. Among the main parameters used in the different industries it can be highlighted the analyses of Free Fatty Acids (FFA), Peroxides (PV) and p-Anisidine (AnV) on oils and fats in the food industry and the analysis of Free Amino Nitrogen, sulphites and alcohol in beer as well as sugars, malic acid and free and total SO2 in the wine sector.

E.E: At what stage is the market where you are currently active?

S.B: The market is pretty well developed in all the sectors in which CDR is involved. With respect to the telematics, CDR plays an important and more then consolidated role as supplier of the companies that manage the motorways in Italy while in the sensoristics sector the market is at development stages, where if the probes to determine conductivity and hardness into the coffee machines have been already released, other probes for similar applications in the same sector are in the development phase. As far as the galvanic sector is concerned, the probes to determine temperature, conductivity, Total Organic Carbon (TOC) and pH are also in a development phase. The most developed sector is definitely Food&Beverage in which CDR has thousands of customers, from the smallest to the biggest ones as international groups, spread all over the world in many different sectors.

E.E: What can you tell us about market trends?

S.B: With respect to the telematics, the market trend is pretty stable based on the structure of the motorways in Italy, while the sensoristics field addressed to the galvanic industry seems very promising and it has very interesting perspectives, as this sector is requiring more and more the improvement of its quality control. The Food&Beverage sector trend is for sure the more consistent one, in which CDR has been having a constant growth of an average of 5-10% per year, over the last decade considering also the Covid pandemic.

E.E: What are the most innovative products marketed?

S.B: Due to its intensive use worldwide in the Food industry the CDR FoodLab® system is the most innovative CDR product.

E.E: What estimations do you have for the rest of 2023?

S.B: Nowadays we have an estimation of growth of about 15% by the end of 2023.