In YIZUMI’s future digital workshop for magnesium alloy lightweight parts, we achieve unmanned production across the entire process from raw materials to final products with automatic production in a smooth flow. In a normal production state, operators just need to monitor remotely rather than direct interfere, greatly improving production efficiency, reducing manual workload, and ensuring employee safety.

In comparison to the traditional magnesium die casting workshop with hot air, frequent litten magnesium, and back and forth technicians/operators, this futuristic workshop appears to be a dream workplace.

In 2009, YIZUMI started its development in Thixomolding machine. And in 2015, we officially launched our Thixomolding machine to the market, and by now, our machines in the market have achieved up to 3 million shots. It significantly benefited from issues in traditional die-casting operation such as molten magnesium alloy’s exposure and transfer, excessive carbon emissions by flame retardant gases, and a high-temperature and flammable working environment.

Furthermore, due to the ignition caused by the occasional leakage of magnesium liquid from the nozzles extraction frequently stops the operation, operators place a high value on machine inspection and problem solving, which also bothers Thixomolding workshop managers. At the same time, the high cost and complexity of maintaining imported long nozzles put buyers in a dilemma. Our R&D team is not satisfied to these conditions. We conducted continuous research and analysis to address the pain points and obstacles.

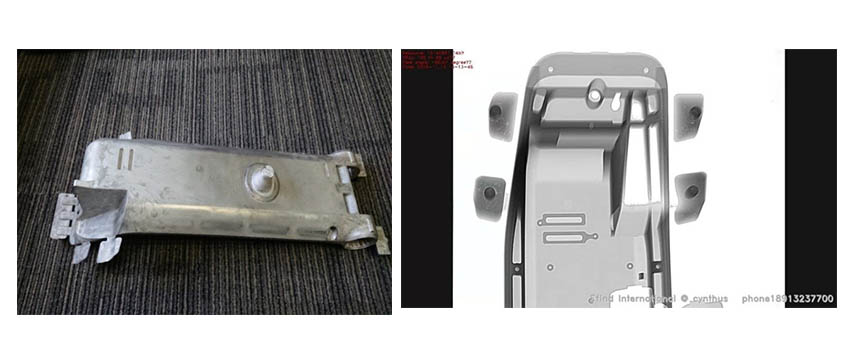

Thixomolding technology originates from injection molding. After years of development of injection molding technology, YIZUMI quickly focused on hot runner solution. However, die casting has a temperature that is 300 °C higher than injection molding and each shot has a speed of up to 5 m/s. Difficulties like die casting mold factories lacking experience in hot runner manufacturing, repetitive tests, as well as conclusion and improvement after failures make hot runner technology development more challenging. Finally, in 2019, the hot runner technology was officially launched, allowing us to feed raw materials straight into the die cavity without pulling back of the injection units.

The hot runner technology keeps the magnesium molten through the heating bands surrounding the runner. The heating bands keep the entire runner’s temperature consistent from the nozzles to the gate. The hot runner system is an extension of the nozzles that saves the need to remove the melt from the runner after machine shutdown. The next shot just needs to reheat the runner to the proper temperature, and the machine is ready to run. The technology is ideal for mass production when raw material prices are high and users have high product quality requirements.

In comparison to current spherical sealing nozzles, YIZUMI Thixomolding machine avoids the risk of magnesium leakage at the nozzle when the injection unit pulls back, resulting in up to 85% material can be used and remove the process of cutting the biscuit. It achieves single gate injection without the use of a three-platen mold. Furthermore, the uniform temperature and pressure within the die cavity reduces deformation of big thin-walled castings. Reduced flow length ratio of the die cavity makes filling easier and reduces insufficient injection of the product end. The temperature is accurately managed to effectively control the semi-solid melt’s liquid-to-solid ratio. And lastly, thanks to its standardized and modular design with a variety of specifications, the equipment is highly adaptable to diverse products.

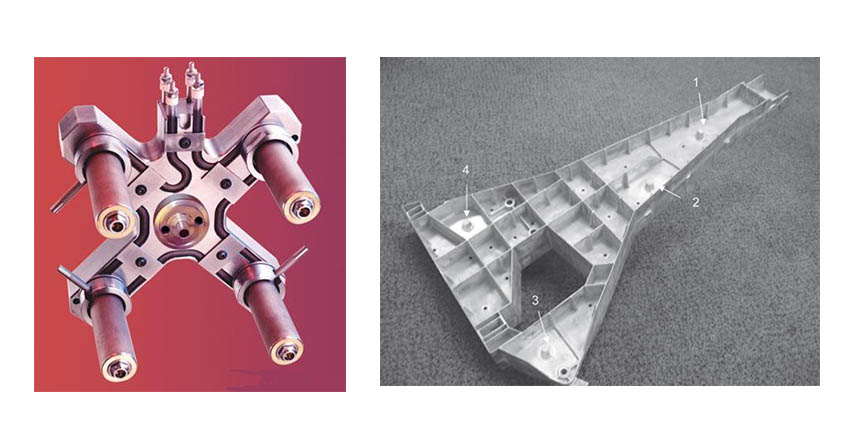

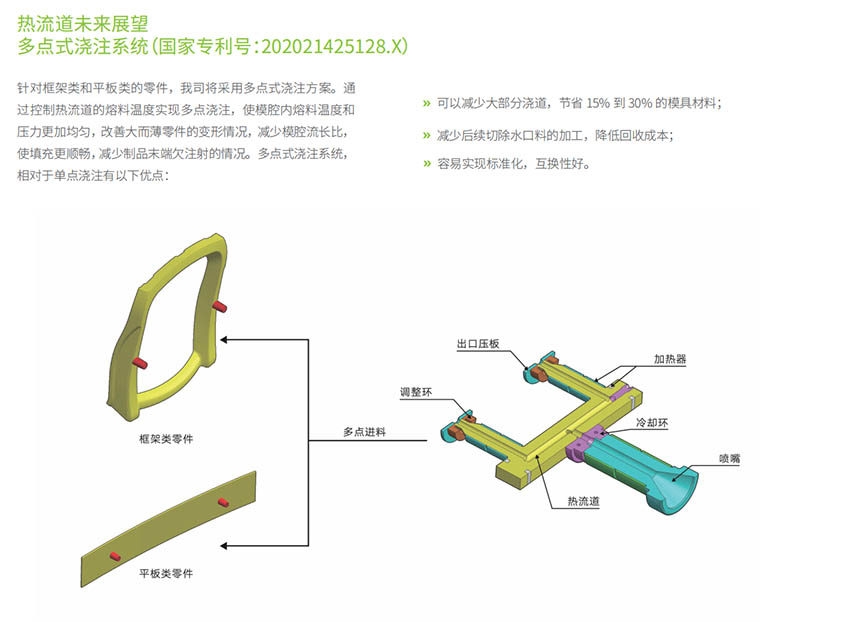

As the demand for large lightweight parts grows, the flow length of magnesium and the injection volume of a single shot will be challenges to cast large lightweight parts with thixomolding. However, one of our inventions, Multipoint Hot Runner Technology, can deal with this challenge perfectly.

Even though the complexity of hot runner system raises the difficulty of mold installation and adds learning content for new customers, it still becomes one of the most popular technologies in YIZUMI if the customers are well trained, so far we have achieved 1.8 million shots with the use of hot runner system.

As digital and intelligent technology advances, the criteria and requirements for intelligent manufacturing become stricter, requiring more innovation in equipment design, business processes, management systems, industrial internet applications, etc. Intelligent manufacturing is a brand new ecosystem characterized by rapid market response, innovative operating models, and green development practices.

We equipped varieties of quality components, including Austria B&R IPCs (Industrial Personal Computers), hot runners, different kinds of sensors, high-precision and fast-responding servo motors, and servo valves. Coupled with precise process mathematical models, and proficient and powerful industrial programming capabilities, we create a safe and comfortable workspace for the manufacturing of lightweight magnesium alloy parts, as well as a digital workshop with simple quality feedforward management, efficient production speed, and precise digital twin technology.

YIZUMI Thixomolding machines provide managers with a panoramic view of the whole production, helping middle managers with ability to see problems and make decisions from a broader perspective and therefore truly strengthening manufacturing’s systematic ability. For example, in the summary and review, team leaders can easily collect segment statistics such as yield, speed, and single equipment performance. And those in charge can attach greater importance to improving the efficiency of their sections.

This is an organizational transformation that blends digitalization into the smallest unit of manufacturing to achieve lower costs and higher quality. YIZUMI’s hot runner technology saves the need for human monitoring and processing, enabling digital zero labor workshops.

In the future, YIZUMI will help more manufacturers build new lightweight manufacturing modes to accelerate manufacturing progress.

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.

Email: Angus@yizumi.com

Website: www.yizumi.com