The digitalization of industry results in a steadily increasing demand for processing power, which is why Kontron equips its Single Board Computers and Computer-on-Modules as well as Industrial PCs with 11th Gen Intel® Core™-i processors. This way, the leading provider of IIoT/Embedded Computer technology combines previously unavailable performance data with additional functionalities that are in high demand, especially in industrial applications.

Since the implementation of the Industrial Internet of Things (IIoT) and Industry 4.0 has picked up speed, processor boards or modules must be able to handle and process exponentially growing amounts of data. The need for computing power as well as transmission bandwidth and storage are rapidly increasing. This is also due to ever more demanding image processing tasks and applications of Artificial Intelligence (AI).

Kontron, as a leading manufacturer of innovative and scalable products for Embedded Computing/IIoT, is continuously developing its products on the basis of the latest semiconductor technology. Working in close partnership with processor manufacturers such as Intel® allows the German premium manufacturer to integrate these technologies into Single Board Computers, Computer-on-Modules and industrial PCs at a very early stage. Thus, ready-to-use products are available shortly after the silicon becomes available, even in industrial-grade versions.

Evolutionary leap in processor architecture

11th Gen Intel® Core™-i processor-based products are already fully available. For classification: As a midrange processor, the Intel® Xeon™ series, along with low-end processors such as the Intel® Atom® series and server processors, form a major focus of the US provider’s portfolio. A wide range of scalability is available and they are subject to further development, which in some cases also takes place in technological steps.

One such step is the transition to the so-called “Tiger Lake” microarchitecture, which was announced at the end of 2020. This involves a new manufacturing process, which results in a structure width of 10 nm instead of the previous 14 nm. As a result, these processors are clearly superior to their predecessors in terms of both possible clock frequencies (up to 4.8 GHz) and energy efficiency.

Two performance levels

The Intel® processors are available in a wide range of variants. Just like some of their predecessors, the letters U and H indicate the main types. Tiger Lake U is a single-chip solution, while Tiger Lake H has two separate chips in one housing. The separate PCH chip provides 30 programmable high-speed I/O lanes as a hub in addition to the 20 PCIe 4.0 lanes. Tiger Lake H thus offers several fast SSD and USB interfaces, as well as 2.5 GbE (instead of the previous 1 GbE) and WiFi 6E Gigabit WLAN.

Unlike with previous architectures, the Thermal Design Power (TDP), on which cooling and power are based, is adjustable within certain ranges. It is 15 – 25 W for Tiger Lake U and 25 – 45 W for the more powerful Tiger Lake H processors. At their presentation, Intel® referred to them as the world’s fastest notebook processors.

Real-time capability as standard

According to Kontron, pure data processing power and transmission bandwidth on the network lines are not the only criteria for the suitability of computer hardware in industrial applications. Mechanical engineering in particular often involves the synchronization of interconnected and interdependent fast processes. Data transmission must be carried out without too much latency, i.e., in real time. It is equally important that the arrival of the transmitted data always remains predictable, i.e. deterministic. The 11th Gen offers both Intel® Time Coordinated Computing (Intel® TCC) and Time Sensitive Networking (TSN) as standard. By adding real-time capability to Ethernet, these enhancements enable the merging of previously separate networks for IT and OT at no additional cost.

Suitable for industrial use for sure!

Functional safety or industrial safety is highly important in industrial applications, especially in mechanical and plant engineering. Safety-related circuits or control systems serve to protect people from injury and machines from damage. In the event of a protection violation, these react by opening a cover, for example, or by putting the machine into a safe operating mode, such as an emergency stop. Ever more complex machines require ever more complex safety precautions and differentiated safe reactions.

The current Intel® processors are particularly suitable for building safety-oriented programmable controllers, meaning that not solely one dedicated processor core can be reserved for safety-oriented applications. The Intel® Functional Safety Essential Design Package (Intel® FSEDP) provides customers with the technical documentation for the development and certification of safety-critical platforms according to functional safety standards.

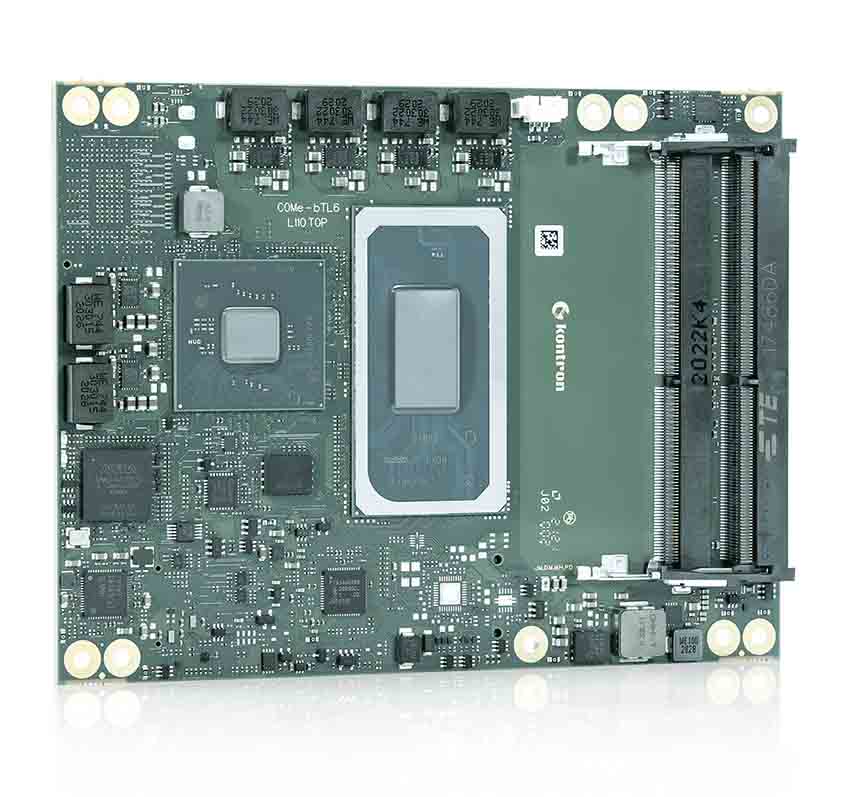

Broad scalability with COM Express®

With Intel®’s 11th Gen processors, PCIe 3.0 and a TSN-enabled Ethernet controller, the Kontron COM Express® module in the Compact form factor enters a new performance class without overly increasing power consumption. For this purpose, it is equipped with a single-chip Tiger Lake U processor with two or four computer cores. These CPUs already have an instruction set for the vectorized neural networks of AI.

In the Basic form factor of the Kontron COM Express® modules, these processors with up to 8 computing cores ensure suitability in high-end applications with high bandwidth. These are the two-chip Tiger Lake H solutions, supported by Intel® Iris® Xe Graphics and Intel® Deep Learning Boost for enhanced AI performance and integrated TSN and TCC functionality.

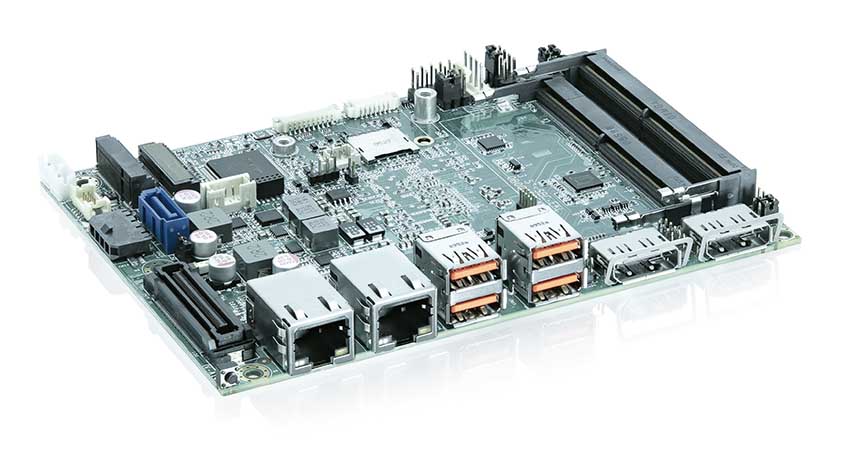

Tiger performance on 3.5”

The 3.5″-SBC-TGL is a 3.5″ Single Board Computer based on the 11th Gen Intel® Core™-i U-Series and Celeron® 6000 Series processors. The designation at Kontron is Tiger Lake UP3. As an additional feature, it is equipped with a next-generation Intel® Iris® Xe Graphics unit. The resulting processor, graphics and AI performance makes it ideal for processing-intensive applications such as AI or Deep Learning.

Due to its excellent suitability for computer vision applications and low-latency deterministic computing, it is very well suited for industrial applications. In addition, the board supports 8K video streaming at 60 frames per second (fps). Using the B2B interface, four independent displays can be controlled simultaneously via DP with a resolution of 4K at 60 fps. The TDP can be configured in the BIOS. This allows the creation of systems that can be adjusted to customers’ individual usage profiles in terms of cooling requirements.

Both the COM Express® modules and the 3.5″-SBC-TGL are available in variants with the extended temperature range of -40 °C to +85 °C suitable for industrial use.

Tiger Lake in Box PCs

Kontron also integrates these processors exclusively in the more powerful two-chip Tiger Lake H version into the new generation of its high-end industrial computers in Box PC format. Equipped with Intel® Core™ i3, i5 and i7 CPUs with up to eight processing cores, the members of the KBox C-104-TGL family with integrated TSN and Intel® TCC functionality are especially suitable for demanding edge workloads and high-end applications with high bandwidth.

Kontron has developed the KBox A-151-TGL industrial PC based on the same processors for particularly data-intensive IoT edge and AI applications. It has an expansion slot on the front (I/O Door), which can be used to add additional functionalities such as fieldbuses, interfaces such as graphics, serial or digital I/Os and Ethernet interfaces. Optionally, the system can also be expanded with 4G/5G or WiFi 6 connectivity.

For all application scenarios

The KBox C-104-TGL family is designed for use in control cabinets in automation environments. The maintenance-free system enables fanless operation up to +65 °C. In addition to the standard version, the passively cooled KBox A-151-TGL is available in an extended temperature range between -40 °C and +65 °C for use in harsh environments. It can be easily integrated into industrial environments by means of top-hat rail mounting or wall mounting.

The units are also optionally available with an additionally integrated Hailo-8™ AI accelerator chip for demanding AI tasks. The chip is very energy-efficient with 3 TOPS/watt and extremely fast due to its integrated memory, achieving an inference performance of 26 TOPS (Tera Operations per Second).

Ensuring extended availability in the future

For industrial users, the long-term availability of hardware is just as important as technical suitability features. This is ensured both by Intel® as a processor manufacturer and by Kontron. Kontron guarantees the availability of functionally equivalent products with correspondingly increasing performance data over very long periods of time.

| Autor: Peter Müller, Vice President Product Center Boards & Modules, Kontron “When it comes to the suitability of computer hardware in industrial applications, pure data processing performance and transmission bandwidth on the network lines are not the only criteria.” |