Easy Engineering: What are the ranges of products sold and what types of services do you offer?

CFT AUTOMATION: Our main area of expertise is machine tools, specifically, we produce and build automatic tool changers with warehouse that have the function of picking the tool from the warehouse and loading it automatically on the spindle of the machine tool.

Our main product range concerns automatic tool changers for CNC machine tools that allow working without operator intervention. The cam exchanger performs fast handling, mechanically synchronized, of clamping, extraction, exchange, introduction and release of the tool.

Other product lines are the pallet changer and roto-elevators, which are fully autonomous mechanical units that perform synchronized handling – lift, rotation and pallet descent – through the application of the cams, driven by a self-braking three-phase asynchronous gearmotor.

Among the services, we offer supply of spare parts to already established customers, technical assistance and overhaul and repair magazines, technical assistance and co-engineering activities with our customers, in the design phase of the machine.

E.E: How do these products / services differ from other types on the market?

CFT AUTOMATION: Over the years we have studied, designed and manufactured tool changing systems that are able to speed up, improve and simplify the handling of tools. This has allowed us to differentiate ourselves from other manufacturers of tool changers for product’s quality.

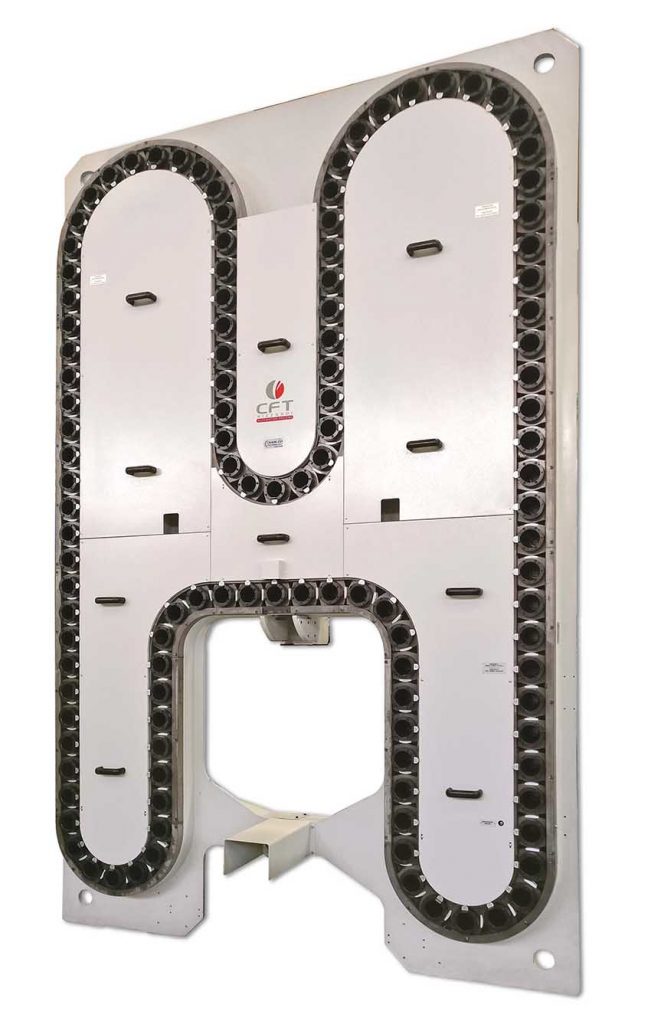

Our most innovative tool changer in fact have a unique feature based on an exclusive patent called Chainless Technology: CFT Rizzardi tool changers system does not use chains, but an innovative system based on self-guided pallets, which are independent from each other, push each other, and are driven by a toothed wheel controlled by a gear motor with a brushless servo motor or other.

At the link below is shown how our tool changer with Chainless Technology: https://www.youtube.com/watch?v=H2R0GILet4M

E.E: What customer profiles are you targeting?

CFT AUTOMATION: They are essentially the manufacturers of machine tools of various types such as, Machining centers, transfer, horizontal and vertical lathes, milling machines, boring machines, laser cutting machines etc.

Thanks to the functionality of tool changers, we were able to acquire metal industry customers such as Breton, Emco Group, G+f Mikron, Gudel, BDM, Industrias Romi; Kuka Group and Qdesign in robotics; Ficep and Bystronic in the laser sector; Bos machines and Brema-Biesse in wood; Almac for watch and jewellery; Dvk System, Gozio transfer and Bucci-giuliani for transfer. The companies to which we sell are domestic, EEC and extra-EEC nature. This shows how our tool changers can be applied to various processing sectors.

E.E: What kind of work do users who use these products / services do?

CFT AUTOMATION: Our product is mainly aimed at machine tool manufacturers, of the above-mentioned types used for the processing of ferrous materials, aluminium, wood, plastic, marble, composite materials etc.

E.E: How do your products / services improve user work?

CFT AUTOMATION: The automatic tool changers and pallet changers applied on the machine tools C.N. allow the use of the machine itself without the assistance of an operator, even for long periods, greatly reducing production costs.

E.E: What innovative features do the products / services have?

CFT AUTOMATION: The advantages of this system are several, listing below:

First of all, the weight of the tool changer is much lower than the weight of the one with chains because the steel chain is very heavy: our pallets are all made entirely of aluminum and therefore very light. This peculiarity is very advantageous when the tool changer is mounted on a mobile upright machine that has to carry the weight of tools together with the carriage.

The second advantage is that with this system we can make paths of tools adapting them to the size of the machine and the available spaces. We even made a tool changer that develops on two orthogonal axis.

Third advantage is that these pallets being single, can be transferred or turned over according to the needs; which would not be possible if there was a chain because they would be connected to each other.

From the point of view of maintenance, operations are simplified, because since there is no chain, constant lubrication is not necessary, nor is it necessary to adjust the tensioning due to its wear.

Last but not least, in case of collision or damage, the single toolholder can be easily replaced directly on the machine itself; operation that would not be possible with a traditional chain-to-chain magazine.

A practical example at the following link: https://www.youtube.com/watch?v=k_eYYKTh94s

E.E: What are the most common problems and how did you help solve them?

CFT AUTOMATION: As for the tool magazines, the problems encountered were due to the lengthening of the chains over time, their weight and the difficulty of handling the tool cell, which we solved with the patented system called ” chainless”.

E.E: What products / solutions are you going to launch in the future?

CFT AUTOMATION: We aim to study solutions with increasingly large magazines, up to 400-500 tools, following the demands of customers and developing tool changers able to handle increasingly heavy tools, up to 50 Kg.

E.E: What are your estimations for the end of the year?

CFT AUTOMATION: After a long period of stagnation due to Covid restrictions, the machine tool market has regained strength in recent months, especially abroad, and we are reaching last year’s order book.

To know more specific info about our complete line of product visit our website: https://www.cftrizzardi.it/site/home.php?id_categoria=11