Winding and More is a manufacturing and software company based in Italy that specializes in the production of standard winding machinery and customized systems, for the automotive, electrical and electronic industries. The company offers a range of winding machines, including automatic and semi-automatic winding machines for various applications. Winding and More, as a start-up company, has been operative since 2016 with a strong focus on research and development to provide innovative solutions to its customers. The company also guaranteed a one (1) hour response time for technical support. Customized training to its clients, to ensure the optimal performance of its products and fast ramp-up after machine/system installation.

The high-class products are 100% designed and manufactured at Winding and More.

Thanks to the strong international networks, they can evaluate and analyze technical developments early and integrate them in our future products.

Interview with Daniel Winkler, CEO and Owner of Winding and More Srl.

Easy Engineering: What are the main areas of activity of the company?

Daniel Winkler: The company’s main areas of activity are:

Design and Manufacturing of Winding Machines: Winding and More Srl designs and manufactures a range of winding machines for various applications, including fully automatic systems.

Technical Support and Training: The company provides technical support and training to its customers to ensure optimal performance of its products. This includes installation, commissioning, training, and maintenance support for its winding machines.

Research and Development: Winding and More Srl has a strong focus on research and development to provide innovative solutions to its customers. The company continuously invests in R&D to develop new products and improve the performance of its existing products.

Customized Solutions: The company also offers customized solutions to meet the specific requirements of its customers. This includes customizing the design and features of its winding machines to meet the unique needs of its customers.

Overall, Winding and More Srl is focused on providing high-quality winding machinery and related services to its customers in the automotive, electrical and electronic industries.

E.E: What’s the news about new products?

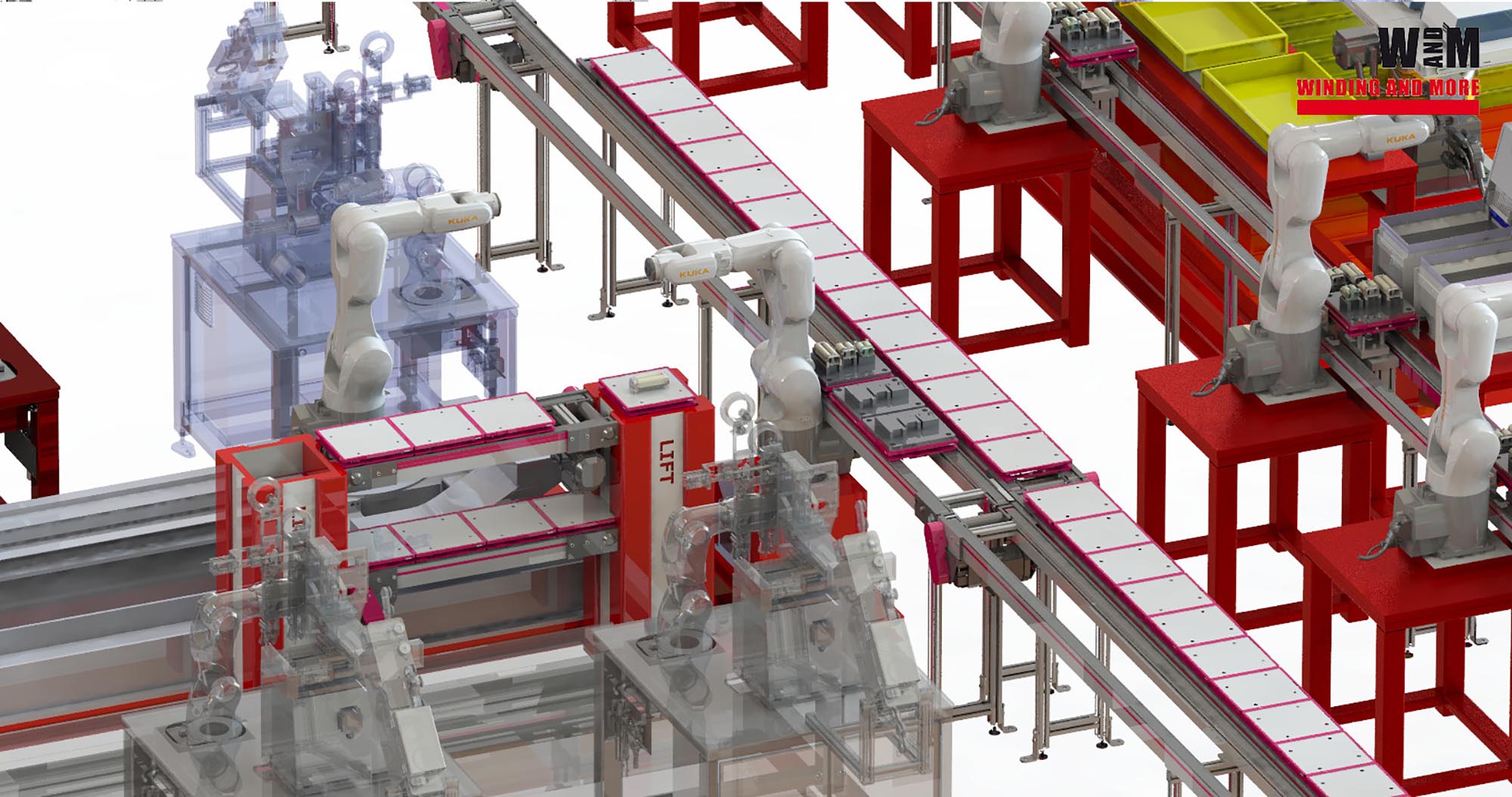

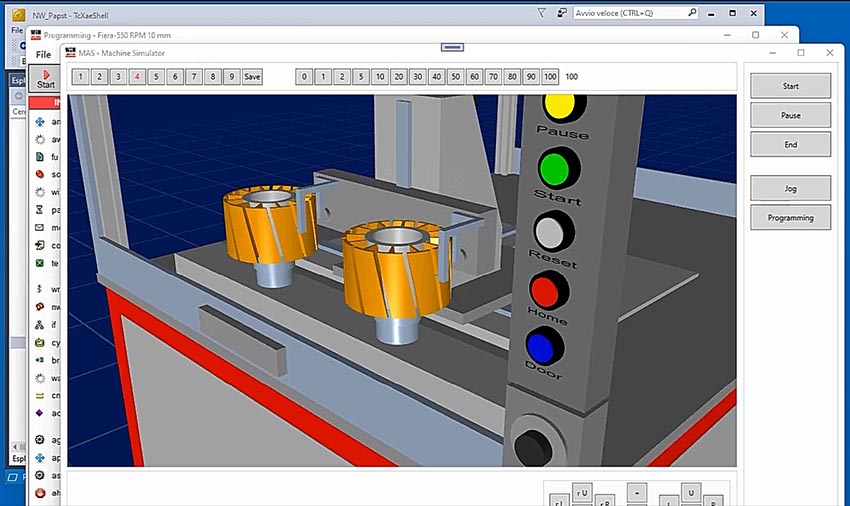

D.W: Winding and More Srl continuously increase the use of its own software as machine simulator, program generators for motor winders, OEE optimizer and robot programming. Beside YASKAWA, any other robot controller could be fully integrated in our HMI via TCP/IP.

This instruments, will make the programming, machine ramp-up and the design for new product simple and fast. The tools and the total integration of HMI will be the game changer for automated systems and winding technology.

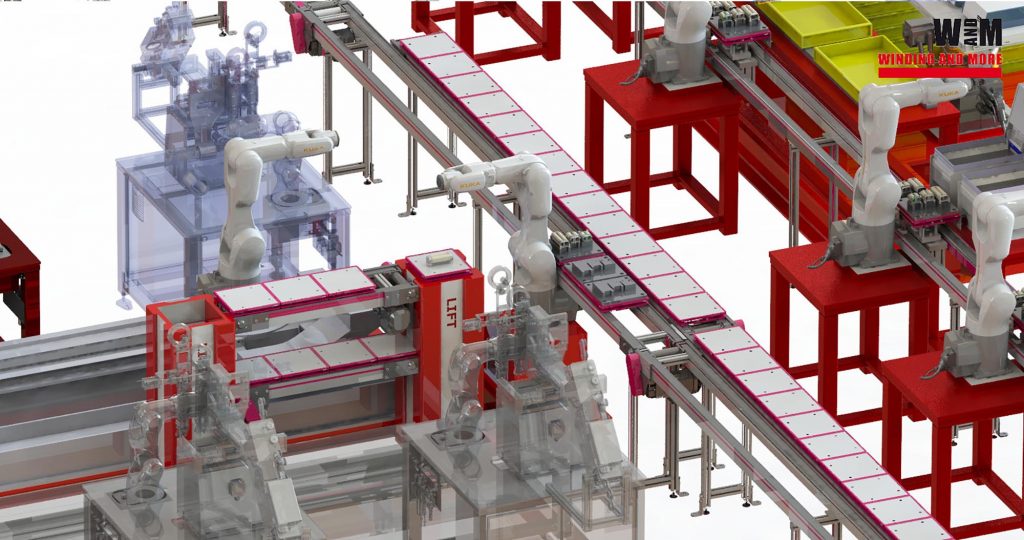

For complete automation systems, our main target is always to integrated all machines and units into one (our) HMI. This is a very big advantage for our customers to optimize or change processes.

E.E: What are the ranges of products?

D.W: We strongly believe in control all single machines and units in one systems. Our software WaM-MCS is key for this solution. The WaM-MCS (Machine Control Software) is completely developed by Winding and More Srl. The software is written in C# and Windows based. The communication backbone is EtherCAT to integrate servo motors, pneumatic valves/cylinders and digital I/O.

The software could be used to program all type of WaM winding machines and auto lines, as well as third party machines, f.e. for Retrofit. WaM sells the software also as separated product for all kind of machines. The user interface is extremely flexible and fast and can be adapted to all kind of requirements. For fast process optimization, you can adjust axis speed 1-100% in automatic mode, incl. the function “brake point” for easy program modification.

E.E: What can you tell us about market trends?

D.W: The shift towards renewable energy sources is driving demand for products that support energy generation and storage, such as wind turbines and batteries. This is likely to create opportunities for companies in the winding industry that supply products and services for these applications.

The development of new materials, such as composites, and improvements in manufacturing processes are leading to more efficient and higher-performing products in the winding industry. This trend is expected to continue as companies seek to develop more sustainable and cost-effective solutions.

The winding industry is highly fragmented, with many small and medium-sized companies operating in different segments of the market. However, there is a growing trend towards consolidation as larger companies acquire smaller players to expand their product offerings and market reach.

The use of automation and digital technologies, such as robotics, artificial intelligence, and data analytics, is becoming more prevalent in the winding industry. This trend is driven by the need for greater efficiency, higher quality, and increased flexibility in manufacturing processes.

The winding industry is under increasing pressure to adopt more sustainable practices, such as reducing waste and energy consumption. Companies that prioritize sustainability in their operations and products are likely to have a competitive advantage in the market. All our machines and systems could be completely turned off, without empty/start machine and without losing actual axis position (Smart Power OFF function).

E.E: What are the most innovative products marketed?

D.W: Winding machines equipped with sensors, data analytics, and machine learning algorithms can provide real-time feedback on the winding process, detect defects, and optimize the production parameters for higher efficiency and quality.

Automated winding lines that integrate different processes, such as Laser welding, IDC-inserting, palettizing, etc. can provide a seamless and efficient production flow with minimal human intervention.

The development of new insulation materials, such as composites or nanomaterials, with improved electrical and thermal properties, can lead to higher-performing and more durable electric machines.

Modular winding machines that can be configured to different product specifications can provide flexibility and adaptability to changing market demands and customer needs.

E.E: What estimations do you have for 2023?

D.W: The demand for winding machines is expected to grow in 2023, driven by increasing demand for electrical and electronic products across industries, such as automotive, energy, and telecommunications. This growth is likely to be particularly strong in developing countries where there is a growing need for electrical infrastructure and industrial automation.

The winding machine industry is expected to continue to benefit from technological advancements in areas such as automation, robotics, and artificial intelligence. This is likely to lead to more efficient and sophisticated winding machines that can handle increasingly complex tasks.

The winding machine manufacturing industry is highly competitive, with numerous companies vying for market share. As such, manufacturers will need to continue to invest in research and development to stay ahead of the competition and provide innovative solutions to their customers.

There is an increasing focus on sustainability and reducing environmental impact across industries. This is likely to lead to a growing demand for winding machines that are energy-efficient and environmentally friendly, and manufacturers will need to adapt to meet this demand.

However, manufacturers will need to stay competitive and adapt to changing market trends to succeed in the industry.