Headquartered in Dublin, Ireland, Innopharma Technology designs and develops Industry 5.0 manufacturing solutions that simplify process intelligence by delivering data in real-time. The company’s solutions enable quick decision-making, reduce time-to-market, and support better outcomes. By offering insight, process control, and intelligence, Innopharma offers manufacturers and researchers the tools to fully embrace the benefits of Industry 5.0.

From the Industrial Internet of Things (IIoT) to automation solutions, Innopharma can guide your journey to smart manufacturing with Eyecon2, SmartX and other products/services.

Interview with Liam Ryan, Sales & Marketing Manager at Innopharma Technology.

Easy Engineering: What are the main areas of activity of the company?

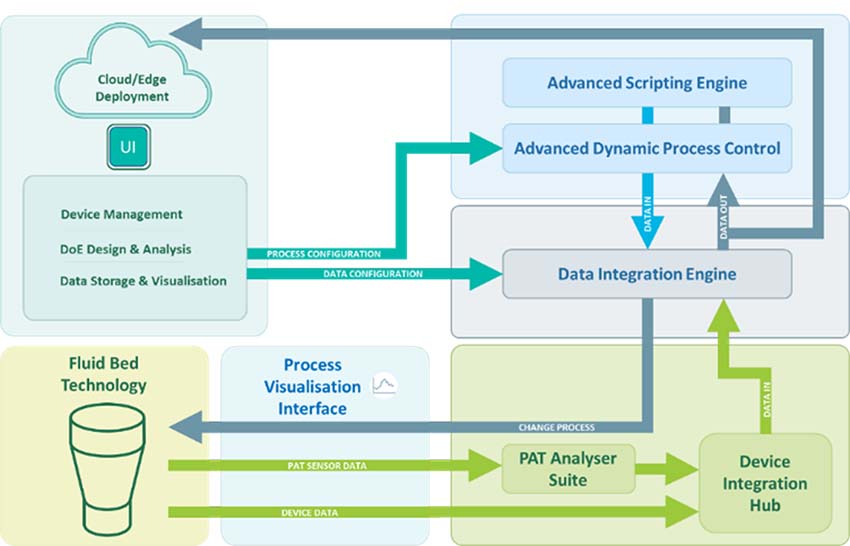

Liam Ryan: One of our two main product offering is SmartX, a process digitalization and automation platform. Built for real-time intelligence and process control. A deployed SmartX enables process automation through low code/no code interfaces, placing the control evenly across all divisions from R&D to production where everyone and every process can be empowered with the manufacturing data SmartX yields.

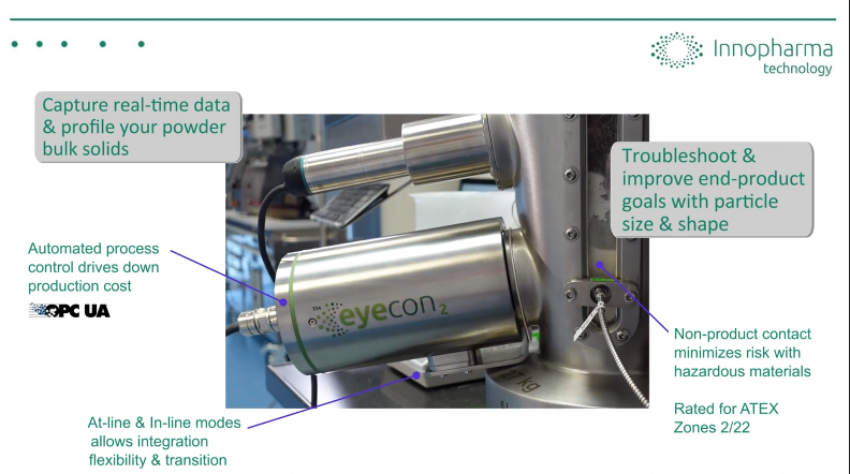

Our second flagship product is the Eyecon2 Particle Analyser a real-time, direct imaging analyser which ranges particles in size from 50 to 5500µm. It is non-destructive, non-contact analytical instrument that can be used either as bench-top test equipment or as a process analytical technology in-line. These images captured by the Eyecon2 are then processed by EyePASS software which uses a particle detection algorithm to measure individual particles. With the introduction of our AI/Machine Learning analytical models, almost any material can be identified.

E.E: What’s the news about new products?

L.R: Our Eyecon2 particle analyser has been drastically updated with the addition of machine learning capability. This allows the software to ‘learn’ from previous analysis to further enhance its accuracy and measure new materials. We see this kind of AI technology as the future in cutting edge equipment.

E.E: What are the ranges of products?

L.R: Our range of products are SmartX – Process Digitalization and Automation Platform, Eyecon2 – Real-time Particle Analyser, Equipment Integration, Consulting, Training & Education.

E.E: At what stage is the market where you are currently active?

L.R: The market that we operate in, mostly pharmaceutical manufacturing, is in a competitive stage. The demand remains high but there are regular entries and generic substitutes to the market. This market is in Industry 4.0 and we are now offering services to help move major companies to an Industry 5.0 model.

E.E: What can you tell us about market trends?

L.R: This market is relatively resistant to adopting new technologies or methodologies. This can be due to the capital investment required to change systems/methods and to the regulatory requirements for new production procedures. However, with greater spend and financial resource availability, the market will continue to evolve technologically.

E.E: What are the most innovative products marketed?

L.R: SmartX is a truly innovative, agnostic, unifying digitalization and automation platform for process equipment. How this product is original and advanced from similar automation hubs is that allows operators without ‘coding’ experience to fully construct lab/manufacturing processes.

A deployed SmartX instance enables process automation through low / no code interfaces, placing the control evenly across all divisions from R&D to production, everyone and every process can be empowered with the manufacturing data SmartX yields.

E.E: What estimations do you have for the rest of 2023?

L.R: For the rest of 2023 and going forward, we see modern industries putting a greater emphasis on data science and analytics to gain insights from the growing amount of data generated, (not just the pharma industry but related industries like chemical, mining, food & berverage etc). This is a natural progression in order to create better, more complex products using more efficient processes resulting in a better, more cost effective output.

This will involve new technologies like AI, Digitisation and Automation which we feel confident in supplying.

Industry 5.0 which focuses on the human element of working alongside smart machines will also become a hot topic in the near future.