RADWAG is an international company with over 50-year long experience in weighing industry. The company employs 420 people, 151 in R&D department, and has 205 sale and service points worldwide, 8 subsidiaries in Poland and 5 representative offices abroad, one of them in the USA. RADWAG product range covers 1983 models of electronic balances which are to be purchased in 150 countries.

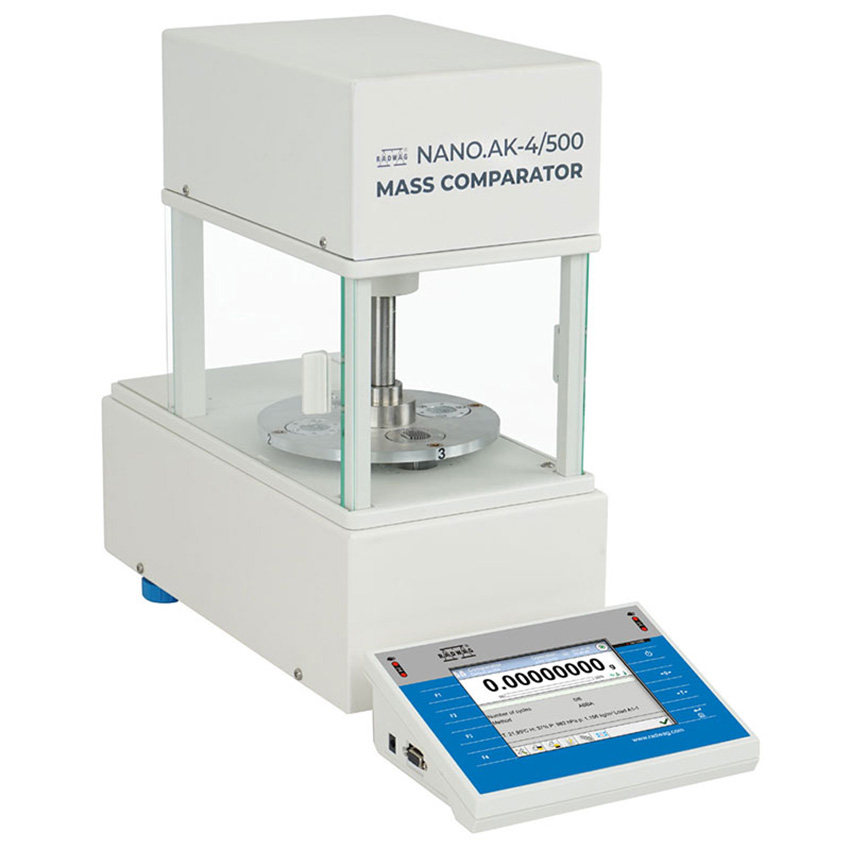

The company manufactures weighing devices and accessories, including nano-comparators, robotic mass comparators, complete range of laboratory and industry weighing systems, balances used on automatic production lines and weighing terminals.

RADWAG offers many innovative solutions, for example laboratory balances of 4Y and 4Y PLUS series as the only ones worldwide feature an in-built ambient conditions module and offer full compliance with 21 CFR Part 11 requirements – no additional software is needed.

Easy Engineering: What are the main areas of activity of the company?

RADWAG: It is worth to pay attention to three main areas of RADWAG activity. First of all, we manufacture complex weighing solutions intended for specific customer demands, for example, the pharmaceutical industry requires compliance with 21 CFR, whereas food branch with HACCP and GMP. Second of all, we offer consulting services with regard to weighing, weighing processes and working conditions for small mass weighing, and finally, the third area of our activity: trainings, webinars, conferences and publications – the idea is simply that “we share knowledge”.

E.E: What’s the news for 2021 about new products?

RADWAG: A device of a special interest is the nano-comparator, which as the first one all over the world enables tests of micro mass standards with a unique readability of 10 ng. RADWAG product range includes also robotic mass comparators, the RMC, a new comparator for mass standards density, the AGV, microbalances of XA.4Y.M.A.PLUS series, PMV 50.PLUS microwave moisture analyzer, a new range of automatic weighing devices for atmospheric air quality tests (RB2, RMC.F, UMA.4Y.F and AK.4Y.F) and DWM checkweighers based on monoblock technology, which enable throughput up to 500 pcs per minute.

E.E: What are the ranges of products?

RADWAG: RADWAG manufactures laboratory balances, industry scales, and Ex, medical, control, PGC and automatic scales. Apart from the above, RADWAG offers indicators and terminals, weighing modules, mass comparators, robotic and automatic weighing systems, devices and accessories for pipetting, mass standards, weighing tables, metal detectors, weighing platforms and respective software.

E.E: At what stage is the market where you are currently active?

RADWAG: We work actively on each continent and in many branches of industry, e.g., pharmaceutical, chemical, petrochemical, cosmetics, food, we also offer solutions for hazardous areas.

Now we focus on pharmaceutical industry. Our product range includes balances intended for pharmacy (AK-6/ST balance for stent weighing, PMV 500 PLUS microwave moisture analyzer and others) and dedicated applications (Statistical Quality Control – SQC, differential weighing, pipetting, formulations, databases and Audit Trail). Additionally, we provide complex compliance, so indispensable in pharmacy, with standards (21 CFR).

E.E: What can you tell us about market trends?

RADWAG: Nowadays the market more often demands complex solutions, and we provide them. Selection of an appropriate product to a process, dedicated application in a device, compliance with standards, validation, periodical post-sales product controls, additional accessories and PC software – we find this all as a complete offer.

Another clearly visible market trend is automation. RADWAG implements automatic solutions, we manufacture devices working without human assistance. This condition is met by our mass comparators, balances for environmental protection, microbalances, scales intended for production lines, known as checkweighers.

E.E: What are the most innovative products marketed?

RADWAG: Many of our products deserve to be called innovative, but if we were to choose one, it would be a device of 4Y series, for example the XA 6/21.4Y.M.A.PLUS balance. Its innovative character is understood by:

- dedicated weighing pan system with holders (among many stents and micro weighing),

- the best repeatability in micro weighing on the market (the best SD),

- automatic balance levelling (Reflex Level System),

- automatically open weighing chamber door,

- antistatic weighing chamber,

- integrated ionizer and antistatic coating of the glass panes,

- automatic adjustment of range resolution to the weighed mass, and as a result – correction of the minimum weight parameter by 30% (Smart Min Weight),

- warnings informing about potential error occurrence during the weighing process (Warnings System),

- module of compliance with 21 CFR,

- mobile control.

E.E: What estimations do you have for 2021?

RADWAG: RADWAG aims do develop constantly and to adjust its product range to complex market demands and individual needs of the customer. Besides we will focus even more on automation of weighing processes and applications dedicated for food and pharmaceutical industries.