Since 1998, AMI Polymer is in the business of silicone elastomeric products and also, other polymeric components which ultimately provide solutions to fluid transfers, sealing, and contamination controls for biopharma, pharma, medical, laboratory, food, beverages, and engineering sectors worldwide.

APPL is having ISO Class VII and ISO Class VIII Cleanroom facilities certified with ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 27001:2013, ISO 13485:2016. also, BPOG extractables program for products for regulatory markets worldwide.

Interview with Simran Singh, Sr. Executive International Sales & Marketing (EU Region) at AMI Polymer.

Easy Engineering: A brief description of the company and its activities.

Simran Singh: AMI Polymer has world-class manufacturing technology with end-to-end process capabilities to fulfill the needs of customers. which include Extrusion Technology with Laser Controlled system, Automatic Hose Production lines, Plastic Extrusion Lines, Automatic Hydraulic Presses for Elastomers & Polymeric engineering components, Laboratory with R&D Equipment, In-house Tooling & Mould making machinery, Laser Cut Machines, and Online Printing as well as Marking systems on products.

Our Strengths

90% Business Contribution from Pharma & Biopharma Industries. Facility Audited by 150+ Companies, ISO 13485 certified & BPOG Studies availaible on Products, Global Business 50+ Countries, 600+ Employees, 45+ Rubber Technologist, Capacity expansion new Facility of 3,50,000 Sq. Area, Nominated by D&B in top 500 companies, 2022, In House Tool Design & R&D.

E.E: What are the main areas of activity of the company?

S.S: Our main activity includes critical media transfer consumable products for Bio-pharmaceutical Industries, Custom-made engineering products and In-house 2D & 3D design capabilities AutoCAD, ActoCad. CAMworks, SolidEdge, NxCAM, Fusion360 and In-house engineering prototype manufacturing. We are proud to share our contribution with engineering custom-made critical profiles in INDIA’S First Indigenous aircraft carrier INS Vikrant.

E.E: What’s the news about new products?

S.S: Recently, we launched our new product lines for biotech Industries. The new product line consists of Single-use polypropylene components like Triclovers with Hose barb, couplers, reducers, end caps and more engineering plastic parts. Apart from this, we also developed the manifold and overmoulded assemblies consist of T, Y, X assemblies.

E.E: What are the ranges of products?

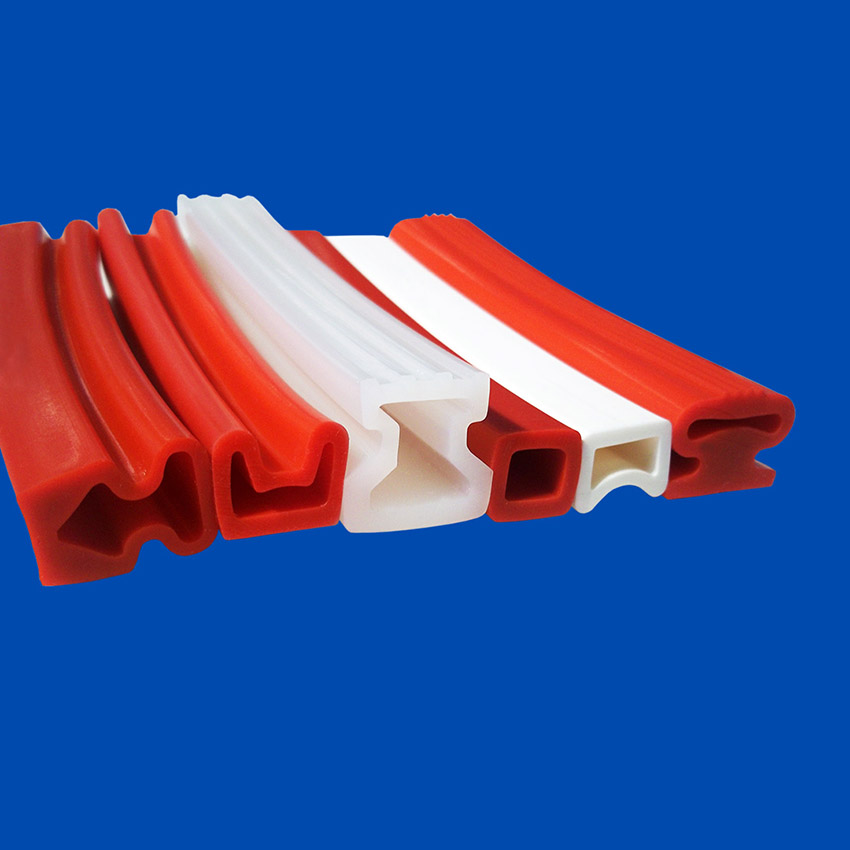

S.S: Critical Tubing’s for bio-pharmaceutical and chemical Industries. Platinum cured silicone, heat sealable and weldable TPE and Viton, Silicone bellows for powder handling systems and tablet punches, Inflatable seals for Original Equipment manufacturers and fluid bed dryers, Silicone sleeves for corona treator machines.

E.E: At what stage is the market where you are currently active?

S.S: We are currently active in the field of biotech Industries and catering the arising demand worldwide for Imapure®Platinum cured silicone tubing and Imaweld® Heat sealable and weldable tubing for critical media transfer like covid vaccine, BCG, Yellow fever vaccine. Single use assemblies and SUS Plastic Components.

E.E: What can you tell us about market trends?

S.S: One of the major trends I have seen happening in the manufacturing industry this year is still manufacturing power by advancements in critical products for biopharmaceutical Industries. The industry is in the midst of a fundamental transformation, as the scale of operations is growing. The year 2022 had bio-pharma companies oriented to staying agile and resilient in regards to disruption bred by the fluctuating market demands and diverse customer needs.

COVID-19 has put the global bio-pharmaceuticals industry into the spotlight with the world urgently working towards a breakthrough in the fight against the pandemic that results positively in the Production of vaccines and Advancements in technologies. The collaboration amongst the Innovation Discoveries of Life Sciences Companies is remarkable. Furthermore, Developments and Improvements in Drug Research Boost in the Volume of Research in the Field. and More Value-Based Pricing of Biotech Products.

E.E: What are the most innovative products marketed?

S.S: Since, we develop major of engineering custom-made products obtained by 3D models, majority of products are unique but If I elaborate about most significant Innovative product that goes to overmoulded and manifold assemblies with all 100% critical compliances and regulations FDA 21 CFR 177.2600, USP Class VI, ISO 10993, E&L Studies from TOXIKON Lab USA, BPOG Testing, EP 3.1.9, GERMAN BFR, NSF-51 and other critical declarations

E.E: What estimations do you have for the rest of 2022?

S.S: Current business dynamics indicate that innovation will continue to drive growth in the rest of 2022 . Pharma and Biotech market will continue digital transformation, aimed at lowering the R&D price while simultaneously enhancing its efficiency, will become one of the leading tendencies in rest of 2022. High-tech solutions for R&D can help many organizations refine multiple processes. We expect growth and increase in supply demands for our newly developed overmoulded and manifold products and engineering product.

AMI Polymer

+919081488817