Protek was born in Italy, in the area of Pescara, in 1996 and was founded by Giulio Fazzini who, today, is still the CEO of the company.

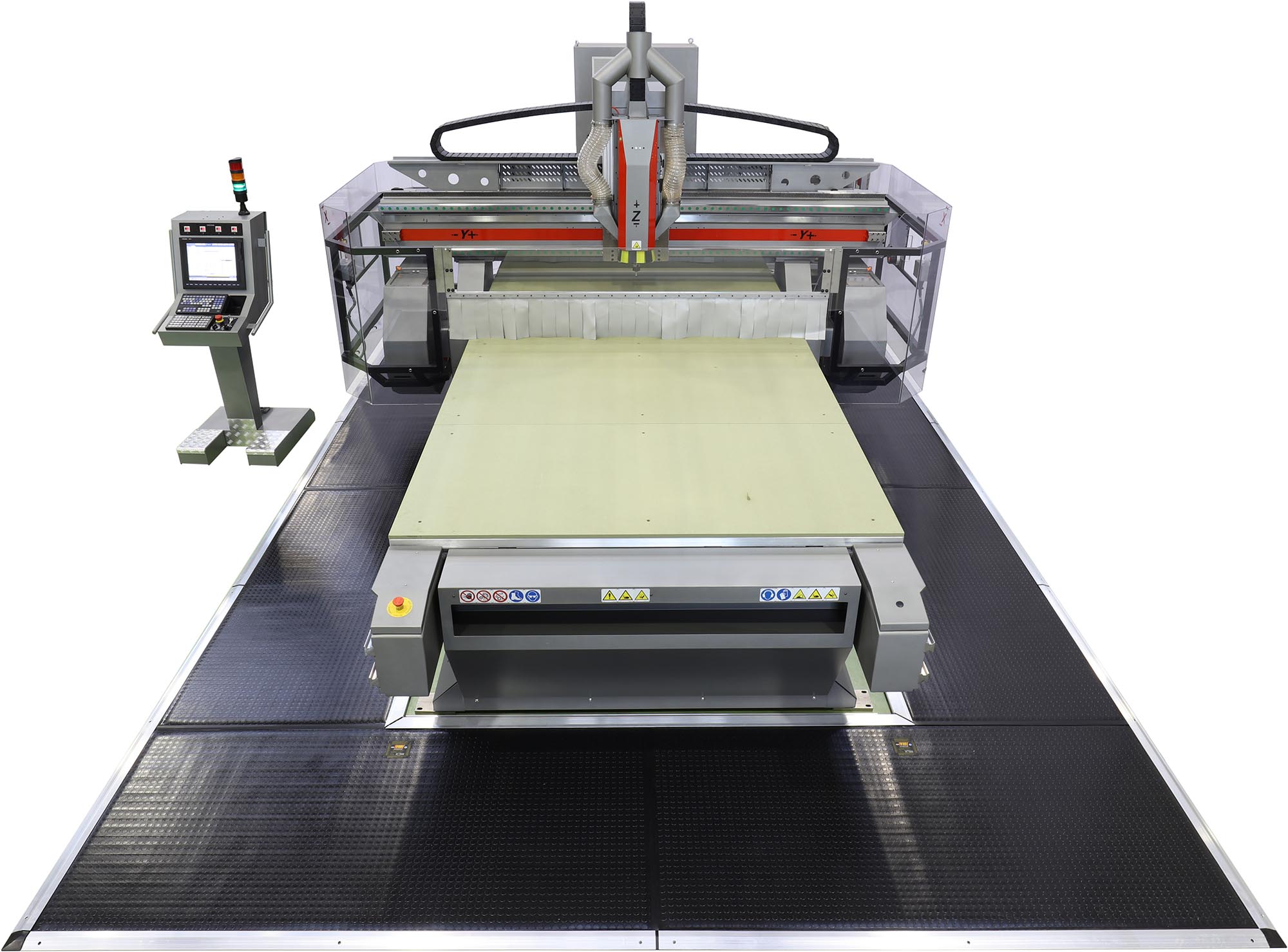

Protek manufactures high quality flatbed CNC machine by providing to customers turnkey solutions that go beyond simply a CNC Router. Protek partners with the customer by giving not only the machine but also the right solutions in terms of tools, software and training.

The first machine manufactured by Protek is concept, which is considered the flagship of the Protek catalogue: this is machine that can cut or mill up to 70 mm of aluminum with an accuracy up to 0.005mm/m

Easy Engineering: What are the main areas of activity of the company?

PROTEK: Protek machines can cut or mill plates of various materials using the routing technology or the knife cutting.

For this reason, Protek machines can cut rigid or flexible materials, optimizing automatically the tool path and the waste/material management with an impressive user-friendly software.

For this reason, there is a wide variety of sectors that benefits from the use of Protek CNC technology: mechanical industry especially for aluminum; the aerospace industry for aluminum, composites and all the materials used for the interior of the planes. Automotive and marine also for interiors, but also gaskets. The signage and large format printing for materials like acrylic, dibond, mdf and similar. Facades and claddings for composite ACP or HPL.

Then packaging, foam and expanded materials and many more sectors.

E.E: What’s the news for 2021 about new products?

PROTEK: We are improving our software that are becoming more powerful and more user friendly. This includes the automatic generation of tool path, the nesting management and optimization, a new software to manage and improve the tool life.

Also, we have recently improved special technologies for „difficult” materials like vermiculite, ceramic fibers and other dusty materials.

With pure solutions the work environment always remains clean with a special care for the operator health

E.E: What are the ranges of products?

PROTEK: Protek manufactures 6 models of machines:

- UNICO TT: a multifunction machine for rigid and flexible materials that can both mill with a router or cut with a modular cutting system. This machine can be equipped with an electrospindle up to 9kW and various cutting technologies

- UNICO TT CONVEYOR: a multifunction machine with a a converyor technology to move the material for easy loading and unloading operations: this machine can also be equipped with a series of unwinder and other automatomatic systems

- UNICO CNC: a smart milling machine that is usually dedicated to signage, plastics and composites. This machine it is an entry level machine in its basic configuration, but the same machine can also be equipped to be used for high and precision productivity

- FRESAT a versatile machine, strong for industrial applications but also fast for lighter industries. It is perfect for the company that works in different fields and that is looking fo a complete machine for both heavy an light sectors

- COMPACT is a heavy duty and precise machine for aluminum and plastics, very well suited for industrial precision applications

- CONCEPT is the flagship of the catalogue, with great capabilities on aluminum and titanium. It is often used in aerospace industry.

The most important thing is that every machine has a very high customization level: multiple gantries, multiple heads technology and many other options are available.

E.E: At what stage is the market where you are currently active?

PROTEK: We mostly operate in Europe, especially in Italy where there is a good tradition of quality companies, and in South Korea. We are now expanding oversea, by placing the first machines in the US. We work a lot with companies that are looking for a non standard product, preferring a tailor made solution that gives access to many market. What we experience most is that the companies that buys the first machine from us have a great increase of work, capabilities in terms of materials and of course, an increase of profit.

E.E: What can you tell us about market trends?

PROTEK: We have noticed that there is in increasing request of cutting advanced and special materials, like composites and foam, especially for the insulation and sound absorbing sectors

E.E: What are the most innovative products marketed?

PROTEK: FRESAT is a great machine that can work in the same time for heavy applications (aluminum, composites, HPL), but in the same time the machine can cut foam and other flexibles materials.

It is a machine for companies that are looking for increasing quality, opportunities and profit.

E.E: What estimations do you have for 2021?

PROTEK: We believe we will have an increase of our product demand in the European area, due to the fact that companies are looking more for quality than low price.