CPM is a leading supplier of high quality machinery and equipment for the animal feed, oilseed, biomass, plastics polymer compounding and recycling of plastics, as well as many other related industries. Established in 1883 and headquartered in the United States, CPM specializes in the production of equipment for particle size reduction, pelleting, cooling, screening, polymer compounding and recycling processing. CPM has a global presence and is renowned for high-quality and commitment to innovation. Their polymer compounding and recycling extrusion machinery is manufactured in Traverse City, Michigan, Lauffen, Germany and Nanjing, China.

CPM’s co-rotating intermeshing twin screw extruders and REs (12 screw ring extruder) lead the industry in quality and value. The RE has tremendous advantages in the tire, rubber and rPET recycling, while CPM’s twin screw extruder machinery offering is a leader in the quality production of engineered resin and compounding processing, globally. CPM has also had a solid presence in powder coating and masterbatch for many years.

With innovation at the forefront for CPM, the company is also further developing the next generation of the high output side feeder. This will improve bulk density and throughput of powder materials for compounding processing. This SPD (separate pressure and degasser) is planned to be on display at the NPE Show in Orlando, Florida this May.

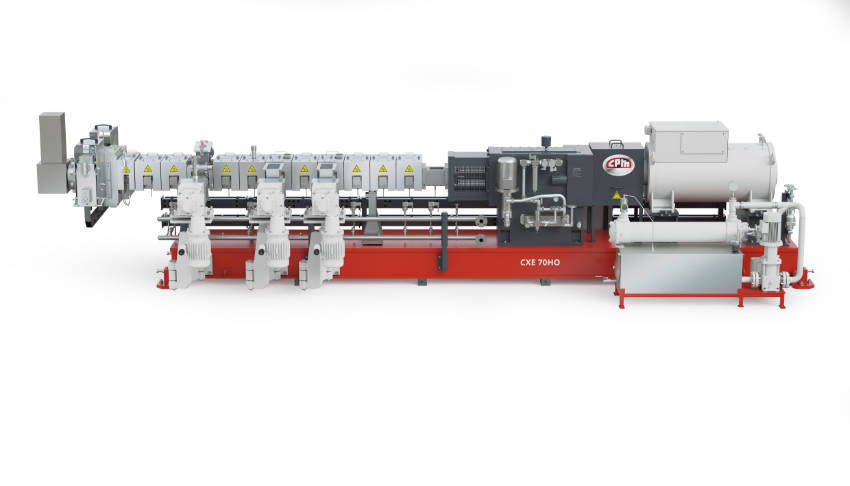

CPM’s ‘CXE’ twin screw extruders range in size from 26mm to 177mm, all within the most globally common 1.55 diameter (Do/Di), with torque density up to 18 Nm/cm3. Given the large number, globally, of the 1.55 geometry machines, the offering of the CXE helps customers from having to requalify their process or screw and barrel profiles or configurations, saving months of further lab verification and therefore, saving money and time.

CPM also offers an intermeshing co-rotating extruder line designed with the global market in mind, as well. Application specific, and designed to meet the customer’s torque, speed and metallurgy requirements, we developed our CX and RXT lines for those sub-segments where higher torque or higher RPM isn’t such a requirement. Given the different process requirements and rate variations for different markets around the globe, the company has developed an offering which is more application specific for these customers.

“Trends in the global market point to higher fill rates, yes, but not always higher throughput rates. Therefore, in listening to our customers, we have developed an approach that fits many markets and global segments with our customers’ direct interests in mind. Our machine designs match the customer’s needs. CPM does not attempt to provide a geometry or design beyond the absolute requirements of our customers. We offer the higher torque density machines, as well as the more standard range, for those many applications that simply do not require higher torque, RPM or higher throughput. CPM is flexible and agile, and we listen to our customer’s needs and process requirements. We are not “over-engineering”, and we like to call this “proper engineering”, focused on application specifics, with valued-added designs in mind.”, says Sean P Doran, VP of Engineered Materials at CPM.

Compounding operations do not wish to be pushed into higher torque machinery, nor higher volume machinery, which requires validation and review, when it is not needed. Therefore, the company’s approach saves time and money for customers.

This year came in with a lot of noise about the global economy, and political changes seem to be possible in many regions, as well. It’s during these times that a more pragmatic approach is best. And when you consider that the 1.55 geometry twin screw extruder machines have a tremendous presence already, globally, it makes sense to stay and work within that platform, which is where CPM shines. This brings inventory stability for customers, and lowers their overall operating cost of operation, longterm. Changing to a new platform and geometry may bring with it unnecessary risks.

The company’s global aftermarket offering, which includes high wear and corrosion resistant materials for elements, barrels and shafts for twin screw extruders, allows CPM to further have a full life cycle support network from new equipment, to refurbishing, to the maintenance of existing equipment for their diverse and global customers, with lower operational costs at the forefront. CPM is well-known for its after-market parts and service support with a broad offering of elements, barrels and shafts.

Trends of “minding the store” literally can mean watching all future operational costs while partnering with a supplier able to meet the customer through application specific designs in new machinery, as well as assisting in a complete aftermarket support, services and processes.