Atlantex Anfahrschutz is a German family-run business led by 2 sisters that specializes on rebounding guarding systems for use in industrial and commercial settings.

Their products are designed to protect buildings, equipment and personnel from accidental impacts and collisions with vehicles such as forklifts or trucks.

The company’s goal is to provide customers with the safest impact protection adapted to their individual needs. Atlantex achieves this through their energy-absorbing products and modular, customized designs.

Interview with Juliane Wätjen, CEO/ Managing Director at Atlantex Anfahrschutz GmbH.

Easy Engineering: What are the main areas of activity of the company?

Juliane Wätjen: Our products are used by businesses across a range of industries, including logistics, manufacturing, and construction.

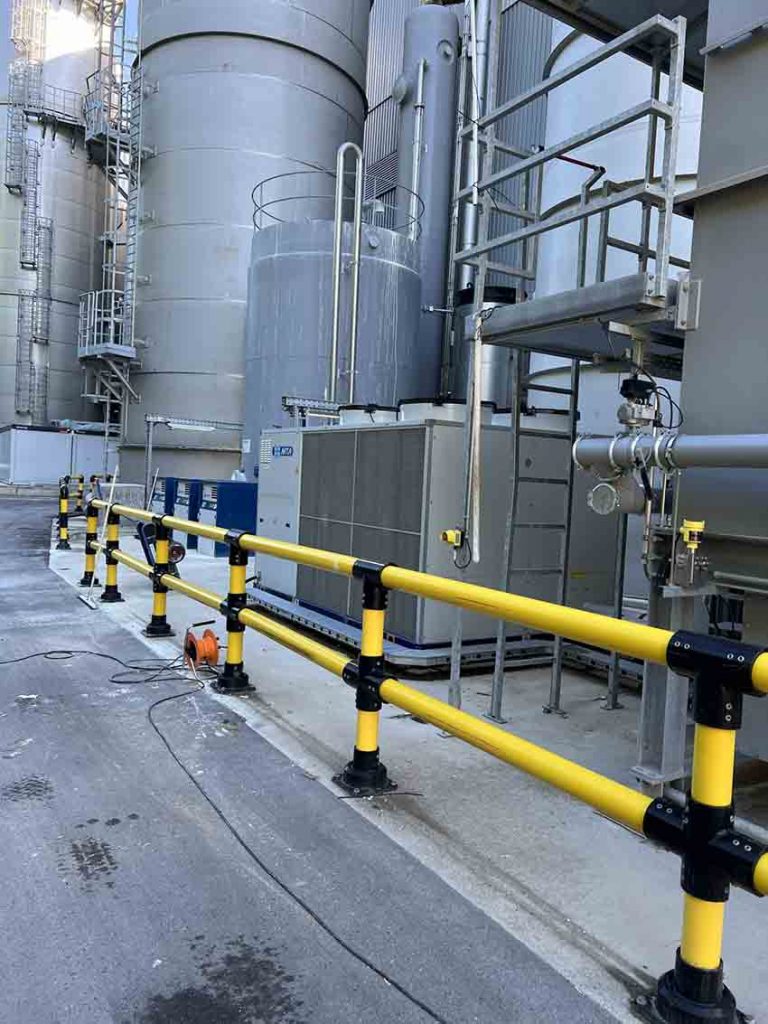

They are also applied to protect gas and oil tanks as well as car parks and parking lots.

E.E: What’s the news about new products?

J.W: All of our guarding systems are flexible, which means they absorb energy upon impact. Flexible systems have significant benefits compared to the traditional rigid systems:

- Damage is reduced to both the vehicle and the guarding system during impact

- Forklift loads are less likely to be lost during an accidental collision

- The guarding systems stays intact after impact and does not have to be replaced

- The floor will stay intact as anchors will not be dislodged, so there are no repair costs

- Vehicle occupants are less likely to be injured as peak impact forces are lessened

E.E: What are the ranges of products?

J.W: Most of our products are modular, which means that with one product type we can create all sorts of systems. Our rebounding steel bollards from SlowStop for example can be slid together via different connectors to create fencing and complex barriers without the need for welding. With double-sided guardrails and the strongest bollards, we can create unequalled barriers up to 120.000 Joule.

Thanks to the modularity of our products, we can cater for any specific need our customers have – from single bollards, column protections, rail systems, rack protection, fences, bumpers, parking separators and much more.

E.E: At what stage is the market where you are currently active?

J.W: The market is saturated with rigid guarding, yet flexible guarding is still a relatively unknown technology that many warehouses and manufacturers don’t know about.

Many are still unaware of the previously mentioned benefits of flexible guarding systems and do not understand why it often makes more sense to invest for the long term.

We are here to change that! Because we know from experience that once customers have tested our energy-absorbing products they will never go back to rigid solutions.

E.E: What can you tell us about market trends?

J.W: Protective guarding systems are an essential element of modern industrial processes, as they provide safety and protection for workers, machinery, and equipment. Let’s take the example of warehouse safety:

As the demand for e-commerce and logistics services continue to grow, so does the need for efficient and safe warehouse operations. Protective guarding systems provide a buffer between vehicle and equipment or workers, minimizing the risk of accidents and injuries.

3 of the current trends we see in protective guarding in warehouses are:

Sustainability

Sustainability is an increasingly important factor in warehouse operations. Sustainable guarding systems are designed to minimize waste and environmental impact.

Our rebounding steel bollards from SlowStop, for example, are designed to withstand strong impacts without breaking. Thanks to the energy-absorbing elastomer in the base, the bollard can tilt up to 20° upon impact and go back to its original shape afterwards. The bollards won’t have to be replaced – you can expect them to last a lifetime.

Safety

The topic of safety is crucial in warehouses for several reasons. Warehouses are inherently dangerous places due to the presence of heavy machinery, high shelving, and the movement of goods, among other hazards. Here are some reasons why safety is so important in warehouses:

Protecting Workers: Warehouses are busy places, with workers operating machinery, moving heavy objects, and driving vehicles. Safety measures such as protective guarding are necessary to protect workers from injuries and accidents.

Reducing the Risk of Property Damage: Safety measures can help reduce the risk of property damage in warehouses. For example, protective guarding can prevent vehicles from colliding with other equipment or objects. This can save companies a lot of money in repairs and lost productivity.

Increasing Productivity: A safe working environment promotes productivity. When workers feel safe, they are more likely to work efficiently and effectively, which can translate into increased productivity and higher profits for the company.

Companies that prioritize safety can create a safer, more productive, and profitable workplace.

Modularity

Modular guarding systems (e.g. SlowStop) are becoming increasingly popular in warehouses. These systems can be easily assembled and disassembled, allowing for flexibility and customization. Modular systems can be quickly adapted to changes in the warehouse layout or equipment, making them an ideal solution for dynamic warehouse environments.

E.E: What are the most innovative products marketed?

J.W: Our rebounding steel bollards from SlowStop! They are designed to absorb and redirect impact energy, providing superior protection for facilities, equipment, and pedestrians.

The bollards have been tested at the official TÜV Rheinland TNO test laboratory and come with a 2-year-warranty.

The benefits of SlowStop bollards include:

Highest strength:The SlowStop bollard type 3 is the strongest surface mounted bollard on the market and can absorb impacts from vehicles up to 40.000kg.

Increased Safety: SlowStop bollards help to reduce the risk of injury and damage caused by collisions with vehicles.

Reduced Damage: SlowStop bollards can help to reduce damage to buildings, equipment, and other property.

Long-term Cost Savings: By reducing the risk of damage and injury, SlowStop bollards can help to reduce the costs associated with repairs, insurance claims, and downtime.

Versatility: SlowStop bollards can be used in a variety of applications, including protection for buildings, equipment, and pedestrians. They can also be used in parking garages, loading docks, and other high-traffic areas.

Durability: SlowStop bollards are made from high-strength materials, making them resistant to impact and wear. They are designed to withstand heavy use and extreme weather conditions, ensuring long-lasting protection.

E.E: What estimations do you have for 2023?

J.W: The material handling industry has been evolving rapidly over the past few years, and the trend is set to continue in 2023. As technology continues to advance, businesses are finding new and innovative ways to streamline their operations and increase efficiency. Some of the trends we expect to see in 2023 are:

Increased Adoption of Autonomous Technologies

The adoption of autonomous technologies is set to increase even further in 2023. Automated guided vehicles, autonomous mobile robots and drones are all becoming more advanced and cost-effective, making them more accessible to businesses of all sizes.

Greater Emphasis on Sustainability

In 2023, we can expect to see a greater emphasis on sustainable practices and technologies, as businesses look to reduce their carbon footprint and minimize their impact on the environment.

This could include the use of adoption of electric vehicles, the use of renewable energy sources, and the implementation of more sustainable packaging and storage solutions. Or the use of our rebounding guarding systems, of course!

Continued Growth of E-commerce

As more consumers turn to online shopping, businesses will need to adapt their material handling processes to keep up with demand.

This could involve the use of automated sorting systems, advanced tracking technologies, and increased warehouse automation to improve order fulfillment and delivery times.

Integration of Artificial Intelligence

We can expect to see more businesses incorporating AI technologies into their processes in 2023 such as predictive analytics, machine learning algorithms, and computer vision to optimize warehouse management and improve productivity.

AI can also be used to enhance safety, with the ability to detect potential hazards and prevent accidents before they occur.