Based in Burlington, North Carolina, BNNano is one of the only companies in the world that produces Boron Nitride Nanotubes at commercially viable prices and volumes. BNNano’s patented NanoBarb™ improves the properties of a bare Boron Nitride Nanotube and is the foundation of a line of products designed to minimize process challenges that historically limit macroscale performance and maximize the potential of nano-enhanced materials.

Interview with Steve Wilcenski, Co-Founder and CEO of BNNano.

Easy Engineering: A brief description of the company and its activities.

Steve Wilcenski: Each defining age of human civilization was shaped by new, revolutionary materials. The Bronze Age enabled advanced farming and hunting. The Iron Age forever revolutionized human tools, weaponry, and established permanent settlements. With the Silicon Age came the computer and the internet. At BNNano, we are ushering in the next age through innovative material science.

Our patented technology is designed to significantly enhance the strength, thermal management, flame retardancy and neutron radiation absorptive capability of materials. An excellent absorber of organic chemicals, the NanoBarb™ can survive very high temperatures, is chemically inert, microwave transparent, and electrically insulating. We have incorporated our technology into targeted plastics and metals boosting their properties so our customers can produce transformative designs and systems.

E.E: What are the main areas of activity of the company?

S.W: Raw Materials

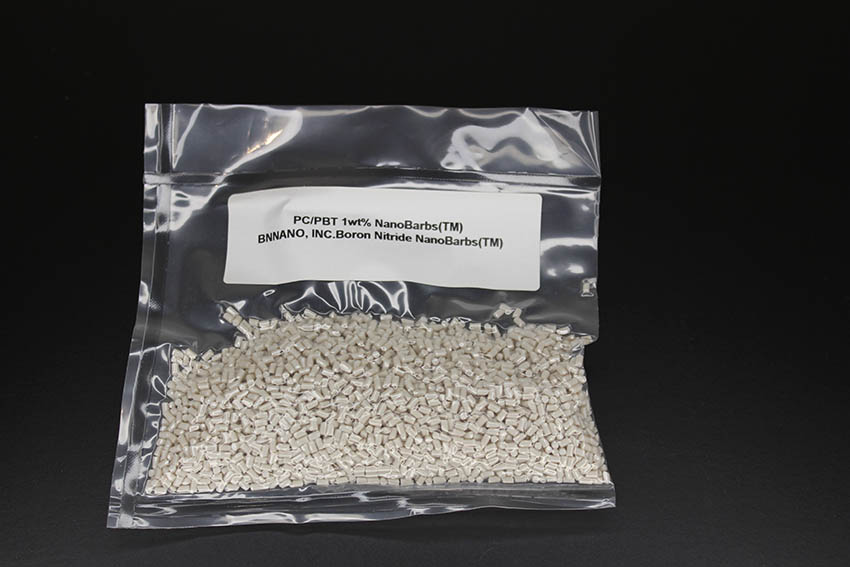

Our NanoBarb™ Powder is a nanoscale additive material when added to base materials (e.g. polymers, metals, ceramics, liquids, and other materials) provides specialized characteristics or enhances the material properties (mechanical, thermal, radiation, and/or chemical).

Additive Manufacturing

Also referred to as 3D Printing or Rapid Prototyping. This emerging field enables the manufacturing of three-dimensional products by adding material, typically layer by layer, rather than by removing material from a solid block.

Analogous to common desktop printers that use ink to produce a 2D document, additive manufacturing uses materials such as polymers and metals to manufacture 3D components. The final product is created by building or adding materials which enables the creation of designs that are more complex than can be produced by traditional manufacturing techniques. Parts that once were an assembly of multiple pieces can now be produced as one part saving time, money, and energy. BNNano’s Polymers and Metal NanoBarb™ Products are being utilized to meet the needs of our Additive Manufacturing customers.

Lightweighting

Across industries, a universal focus is the optimization of size, weight, power, and cost. Lightweighting is the process of removing unnecessary weight from a component or assembly. Designers and manufacturers lightweight products by substituting materials (i.e., polymers, composites, and metal alloys such as aluminum) or by changing and optimizing designs. Advanced materials are critical because they can provide stronger materials with better thermal properties helping manufacturers meet stringent performance requirements at the lowest possible weight.

Advanced materials are typically environmentally friendly, reduce carbon footprints, and offer advantages such as corrosion and oxidation resistance, high electrical and thermal conductivities, low density, high reflectivity, high ductility, high strength, and cost-efficiency. As a result, advanced materials have extensive applications in the aerospace, defense, healthcare, electronics, construction, automotive, and packaging industries across the globe. BNNano’s complete line of NanoBarb™ Products can be utilized to meet the needs of Lightweighting customers.

Products

NanoBarb™ Powder is an additive that augments and improves performance across numerous applications. NanoBarb™ Powder can be added to a wide range of materials such as metals, ceramics, polymers, liquids, resins to name a few. NanoBarb™ Powder is our original product and is the foundation for our expanding product portfolio.

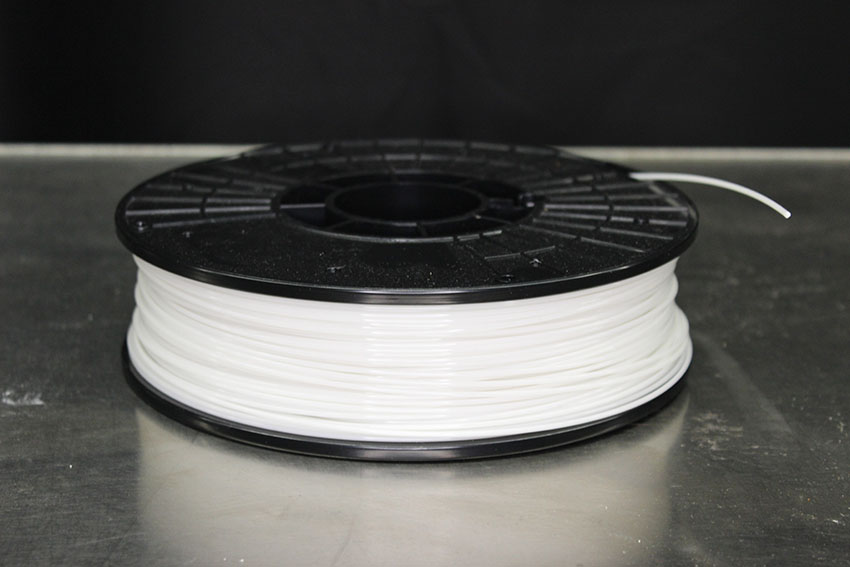

NanoBarb™ Polymer Filaments are designed to be used for Additive Manufacturing. The NanoBarbs™ provides a super strong backbone while the crystallites act as barbs, interlocking with the polymer matrix creating an ideal material for demanding 3D Printing applications.

NanoBarb™ Aluminum Master Alloy is a specially engineered pellet which contains a high percentage of NanoBarbs™ compounded into pure aluminum. When added to molten aluminum during the alloying process the NanoBarb™ Aluminum Master Alloy increases material strength giving aluminum the potential strength of steel or titanium.

E.E: What’s the news about new products?

S.W: Water Purification Products:

BNNano, Inc is solving one of the country and world’s most pressing problems – clean drinking water without toxic “forever chemicals”.

In a report published in October 2022 there are 57,412 sites total in the US that are contaminated with PFAS, including:

- 49,145 industrial facilities

- 4,255 wastewater treatment plants

- 3,943 military sites

- 519 airports

and the EPA has identified more than 120,000 US locations where people may have been exposed. The EPA and other government bodies are currently PFAS solution focused and allocating billions of dollars for this significant public health and environmental issue, but current water technology is not equipped to solve the problem.

BNNano’s breakthrough technology under development, has the potential to be the perfect scalable PFAS destruction solution domestically and abroad.

E.E: What are the ranges of products?

S.W: We manufacture the raw material, Boron Nitride NanoBarbs, and we also extrude enhanced polymers for additive manufacturing and injection molding.

We also produce the Aluminum Master alloy.

All of the production is performed in our factory in Burlington, NC, USA.

E.E: At what stage is the market where you are currently active?

S.W: We sell the raw material (boron nitride nanobarbs) to private companies, academia, government labs, and organizations around the world.

Steve Wilcenski, Co-Founder and CEO of BNNano.

We sell the enhanced polymer filaments for additive manufacturing and Injection molding to private companies, academia, government labs, and organizations around the world.

We sell the aluminum master alloy to select customers primarily in the United States.

E.E: What can you tell us about market trends?

S.W: Lightweighting continues to be a priority for industries ranging from Defense, aerospace, automotive and consumer products, and with this need our materials are well positioned to address these objectives. We are saw significant growth in sales of our nanobabrs in 2022 over 2021 and we expect that trend to continue.

We released our enhanced polymers in Q3 2022 and we are getting excellent feedback on the performance of our products and we expect this portion of our business to have significant growth in 2023. The need for better materials for additive manufacturing is well documented and the products we provide have mechanical properties that will enable new opportunities for additive manufacturing.

E.E: What are the most innovative products marketed?

S.W: Our line of water filtration products is the most recent products that we are developing and they are in high demand to help solve the PFAS contamination problem that is occurring around the world.

E.E: What estimations do you have for the rest of 2022?

S.W: 2022 will close as the most successful year that we have had so far. All parts of our business have experienced growth and we will be completing the product development for our first water filtration products before the end of the year.