Boldan is the leading expert in Cured-In-Place Pipe systems. A cured-in-place pipe (CIPP) is a trenchless rehabilitation method used to repair existing pipelines. No digging is involved in this trenchless process, making for a potentially more cost-effective and less disruptive method than traditional “dig and replace” pipe repair methods.

The company develops, manufactures and distributes high-end CIPP products and materials through their global distribution network.

Boldan’s innovative and professional staff has extensive and diverse experience in pipe renovation projects all around the world.

Easy Engineering: What are the main areas of activity of the company?

BOLDAN: Boldan provides a comprehensive service concept that includes all the equipment, materials, training, and technical support needed for successful pipe renovation projects.

More than a hundred plumbing companies around the world are trusting the Boldan In-House Lining System.

E.E: What’s the news for 2021 about new products?

BOLDAN: Launch of the Boldan In-House Lining System in European countries 2021.

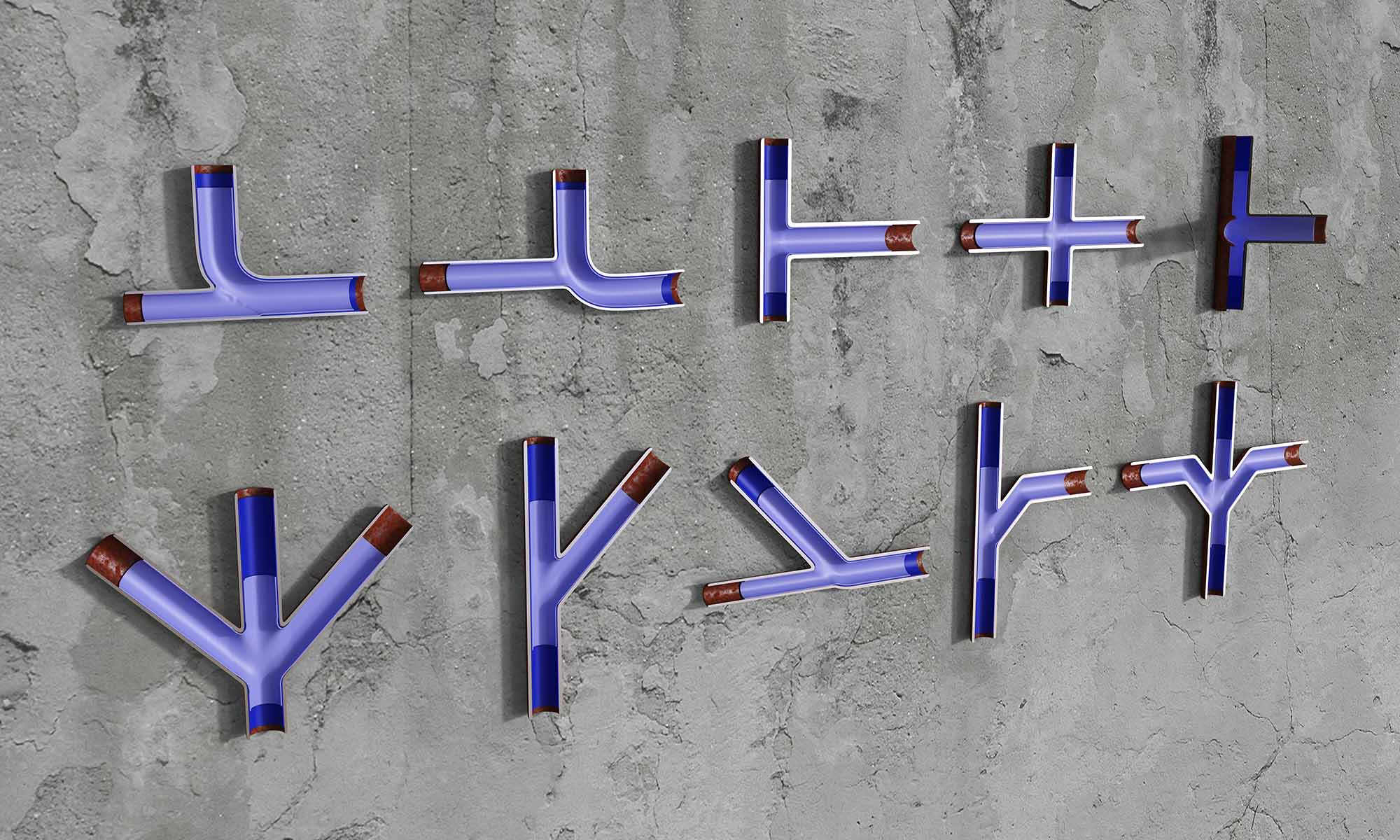

Boldan In-House Lining System is the most extensive pipelining system on the market that covers all materials and accessories for sewer renovation.

Materials have been tested to be compatible, and the entire system also watertight for branch joints.

E.E: What are the ranges of products?

BOLDAN: Pipe cleaning machines, Cured-In-Place Pipe (CIPP) liners & epoxy resins, and Connection Liner System.

E.E: At what stage is the market where you are currently active?

BOLDAN: Trenchless technology is a globally vast growing market.

For example, in Finland, more than 10,000 sewer systems in apartments have been renovated with the Boldan In-House Lining method.

The main reasons for its popularity are that there is no need for moving out and the short duration of renovation makes it customer-friendly. All the sewer pipes in the apartment can be renovated in less than a week.

E.E: What can you tell us about market trends?

BOLDAN: Plumbing companies around the world increasingly value the know-how of the renovation of small-diameter pipes.

Also, green values are appreciated nowadays – pipe renovation with trenchless technology is environmentally friendly; there occurs neither dust nor hazardous waste. The carbon footprint of the method is relatively small.

E.E: What are the most innovative products marketed?

BOLDAN: The most innovative products are:

- VPC15 Pipe Cleaning Machine;

- A new handheld controller switch allows operators to work in challenging working positions and spaces;

- EIPS (Electric injury prevention system) electric safety system prevents injury and extends the life of the product;

- No wearing parts or constant adjustments as in conventional clutch;

- The full aluminum frame makes the equipment lightweight, only 18kg.

E.E: What estimations do you have for 2021?

BOLDAN: Maintaining market leadership also in the year 2021.