CASTOR is a software company that enables manufacturers to optimize their manufacturing by identifying suitable parts for 3D printing, automatically. CASTOR’s easy-to-use software helps manufacturers to scale up their additive manufacturing journey, offering a wide range of advanced capabilities tailored to each organization’s needs, to utilize the benefits of industrial 3D printing.

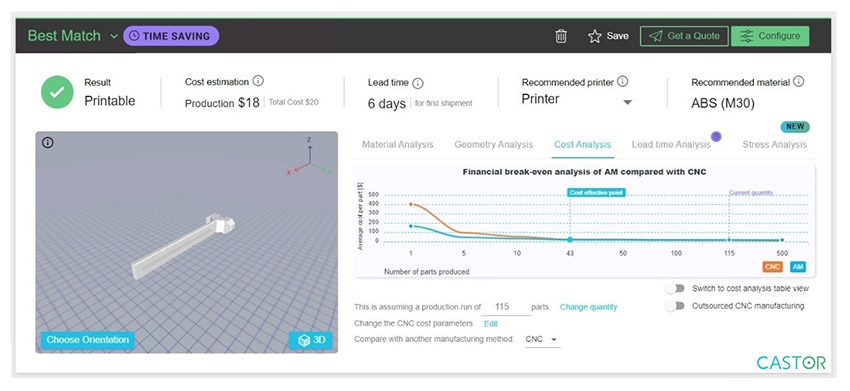

The software is able to analyze thousands of parts and assemblies at once, suggests best-match materials and 3D printing technology, carries out geometry analyses, and identifies redesign opportunities like weight reduction and part consolidation. It estimates the cost and lead-time for each part and connects the manufacturer to a service bureau that can print and supply the part according to requirements.

Easy Engineering: What are the main areas of activity of the company?

CASTOR: We help manufacturers scale up their AM journey, that means we works with different manufacturing companies various industries – aerospace, defense and military, automotive, railway, food and beverage and consumer goods. Our customers’ initiative can range from cost reduction to supply chain improvement, production flexibility or sustainability – we can tackle almost every initiative that is related to improving and optimizing production by utilizing Additive Manufacturing. Our software covers many aspects of AM production and includes analyses such as cost and material analyses, deep geometry analyses, lead time and stress analyses.

E.E: What’s the news about new products?

CASTOR: Earlier this year, we launched an exciting and unique feature – the Carbon Emission Calculator. The calculator reveals the amount of CO2 emissions that can potentially be saved by using Additive Manufacturing instead of Traditional Manufacturing. The calculation behind the CO2 analysis takes into account various parameters along the full lifecycle of the product – such as product manufacturing, transportation, material production and more. The release of this new innovation followed by a lot of interest from the industry since it provides manufacturers, for the first time, with clear valuable information that has an impact on sustainability considerations and high-level decision-making.

Last year we launched another significant innovation which was very anticipated by the industry – CASTOR’s 2D analysis, which provides the ability to discover printability of parts using 2D drawings. With that capability, we offer a feasible way to automatically analyze design files and gain deep valuable data and knowledge regarding the potential of AM, even for companies whose CAD files are not at reach.

E.E: What are the ranges of products?

CASTOR: CASTOR’s line of products includes 3 main products:

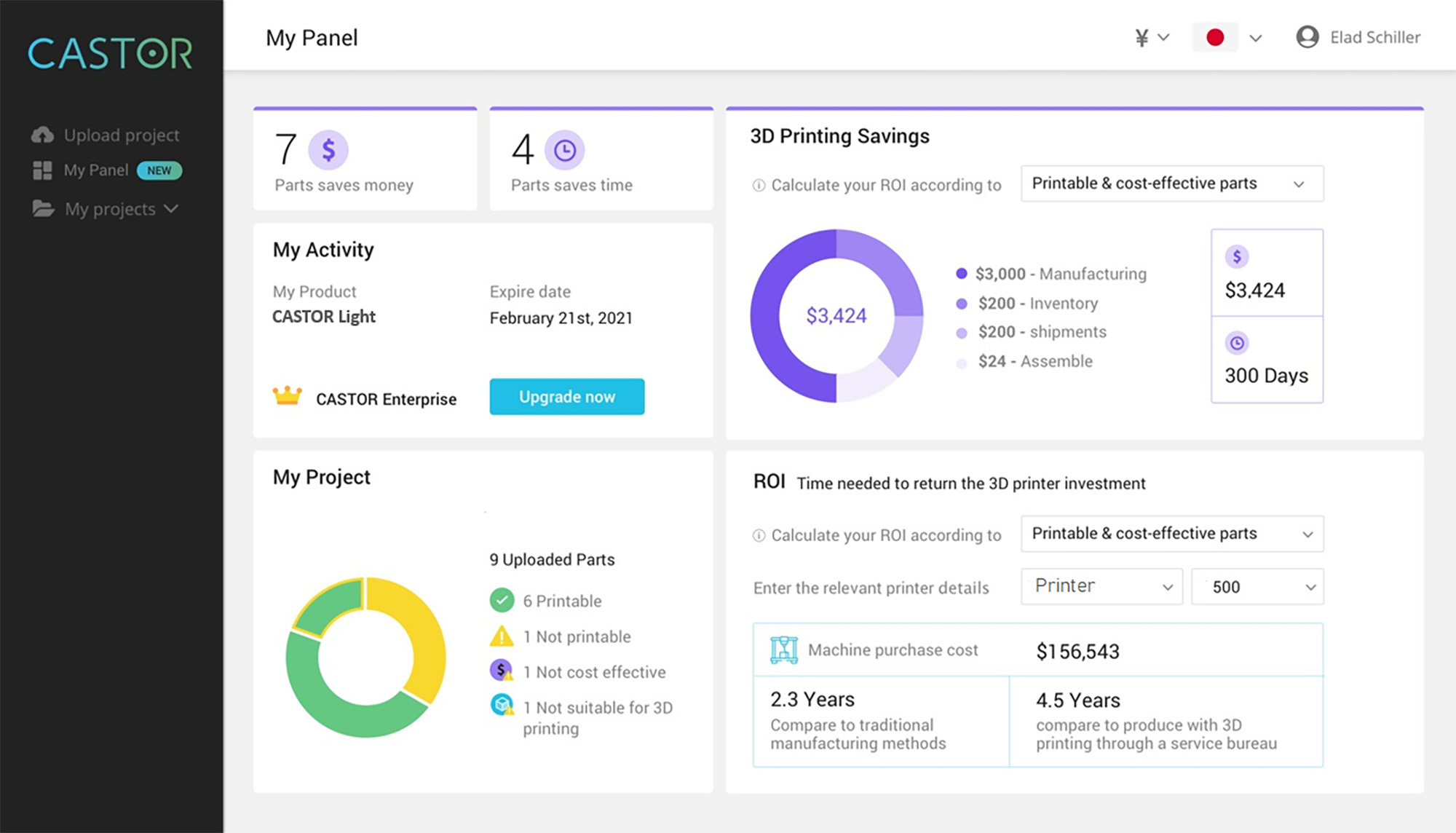

- CASTOR Light; the basic tier for AM new adopters wanting to find the low hanging fruits suitable for 3D printing out of existing CAD files.

- CASTOR Enterprise; which includes more advanced re-design capabilities and aiming at AM experts. This version includes the option to analyze 2D designs and offers more types of deep analyses.

- CASTOR White Label; a fully branded tailor-made platform which is fully cuztomized to the customer’s needs, providing lead generation tools to enhance AM business.

E.E: At what stage is the market where you are currently active?

CASTOR: The market’s readiness for 3D printing technology has increased substantially in the last few years. It is clear to almost every manufacturer that the technology is mature and that it can disrupt the way they manufacture. Most of them, though, still struggle with identifying exactly if, when, and where they can apply additive manufacturing to profit from the technology’s advantages. Companies’ main problem is not having enough in-house expertise to know, out of all the parts they produce, which are the parts that make sense both technically and economically to 3D print. That part-identification challenge is a problem that all companies face at the beginning of the manufacturing workflow. We are working both with companies that have already adopted AM but improve the efficiency of the process and scale-up their use of AM, as well as companies who are at an earlier stage of their journey with 3D printing.

E.E: What can you tell us about market trends?

CASTOR: Since Covid-19, we are witnessing companies’ mission to optimize supply chains and find revolutionary solutions for improving their supply chain resilience – this trend is still very much going on. Another very strong initiative that we notice is the focus of organizations and governments on sustainability, and the understanding of how AM can benefit and provide more sustainable solutions for manufacturing.

Additionally, the demand for automation in AM is growing and manufacturers are searching for automated tools that help them reduce costs, optimize their manufacturing processes and improve overall effectiveness.

E.E: What are the most innovative products marketed?

CASTOR: Some of the more interesting innovations that we see are a result of partnerships between companies within the AM industry. Those collaborations can create innovative products and holistic platforms that provide users with a set of tools to manage their AM production processes more efficiently. For example, the CO-AM platform by Materialize takes software solutions from all stages of the workflow, under one roof, and offers manufacturers a single platform to plan, manage and optimize every stage of their AM operations. We believe that these kinds of collaborations create a larger value for the end-user and contribute to the goal of expanding the adoption of AM, and this is the reason why CASTOR was one of the first companies to partner with Materialize and join the CO-AM.

E.E: What estimations do you have for 2023?

CASTOR: We anticipate that technological developments will continue to occur and that the overall use AM will keep growing widely. We will keep seeing the trends mentioned above – sustainability, supply chain solutions and automation, grow and affect decision makers through the organization. Companies will look for the tools that can be a game changer for their manufacturing and will be willing to invest in them – tools that will help them to become more efficient and to utilize the benefits of 3D printing technology in a much larger scale, using smart algorithms and automation.