Marcelissen Food Processing Machinery has been a household name in the food processing machinery market for the past 70 years, specializing in potatoes, carrots and other tuberous vegetables. Throughout its existence, Marcelissen has showed itself to be an innovative and reliable partner within the food processing industry.

Over the past decades, Marcelissen has obtained and maintained and excellent reputation in the market. By delivering appealing projects, high-quality products and innovative machinery, they go the extra mile for customers to ensure satisfaction.

With their expertise, Marcelissen has not only further optimized machines so that they permanently meet the wishes and requirements of customers and industry standards, but also adapted them to suit new markets such as canned fruit & nuts.

The company delivers high-quality turnkey solutions that keep customers’ production processes running profitably and responsibly. They do this under the credo: ‘we have never failed to solve a problem’. With this belief, the company embraces every challenge with both hands.

From their home base in Venlo, Marcelissen provides in-house R&D, engineering, production and 24/7 service & support to customers worldwide. Their machines are currently in use in well over 100 different countries. Every day, the company expands boundaries together with their network of worldwide agents and dealers who share Marcelissen’s DNA.

Interview with Sjors Vullings, Manager Sales & Marketing at Marcelissen Food Processing Machinery.

Easy Engineerig: What are the main areas of activity of the company?

Sjors Vullings: In fact, we serve three groups of customers.

- Small processors and catering businesses

- Farmers and medium sized processors

- Industrial multinationals

Each customer group we serve with different machines from our portfolio.

Small processors and catering businesses

This customer segment we serve mostly with our Batch peelers, Slitmaster fries cutting machines and Sliver Remover sorting machine that we especially developed for this group.

Farmers and medium sized processors

This customer segment we supply with complete (sometimes custom-made) production lines to process potatoes, carrots, beets and other root vegetables. This means that we supply production lines including washing machines, destoning machines, abrasive and knife peeling machines, cutting machines, sorting machines but also optical grading machines.

Industrial multinationals

This customer segment we only supply with a couple of machines but we supply them to companies all over the world. The machine we sell most is the Sliver Remover. This Sliver remover is used by every major french fries production company (Cavendish, Lamb Weston, Farm Frites, Aviko etc.) but has also taken a large place in the pistachio business as a sorter after peeling. Customers are companies like (Nichols Farms, Monarch Pistachio etc.) lastly, the Sliver Remover has become the standard in the canned fruit processing business to be used to sort out small particles. This means they are used in the businesses concerning peaches, cherries, berries, strawberries, tomatoes etc. Customers are: Del Monte, Pacific Coast Producers, Labridis bros SA etc.

In addition, we sell large, industrial knife peelers to the french fries production companies to be used to re-peel the potatoes.

E.E: What’s the news about new products?

S.V: As said we have developed our own Optical Grader.

E.E: What are the ranges of products?

S.V:

- Washing

- Destoning

- Peeling (abrasive & knife)

- Optical Grading

- Cutting (sticks, slices but also halving and quartering of root vegetables)

- Sorting (diameter, small pieces, length)

- Inspection tables

- Transport connections (conveyors, augers etc)

- Control panels (inhouse software development and assembly of control panels)

E.E: What can you tell us about market trends?

S.V: Automation: The use of automation in food processing machinery is becoming increasingly prevalent, as manufacturers look to improve efficiency, reduce labor costs, and enhance product quality and consistency.

Sustainability: Sustainable manufacturing practices and environmentally-friendly machinery are becoming more important to customers. Therefore, we are more and more investing in developing machinery that minimizes waste and energy consumption while also improving product quality and efficiency.

Digitalization: The digitalization of food processing machinery is making it easier to monitor and control the manufacturing process. The use of sensors, cameras and data analytics allows a more precise control and optimization of production processes, resulting in higher quality products and reduced waste.

E.E: What are the most innovative products marketed?

S.V: This is most definitely our Optical Grader. We developed it ourselves over the course of several years and at the moment it is the most accurate grader for peeled potatoes in the market.

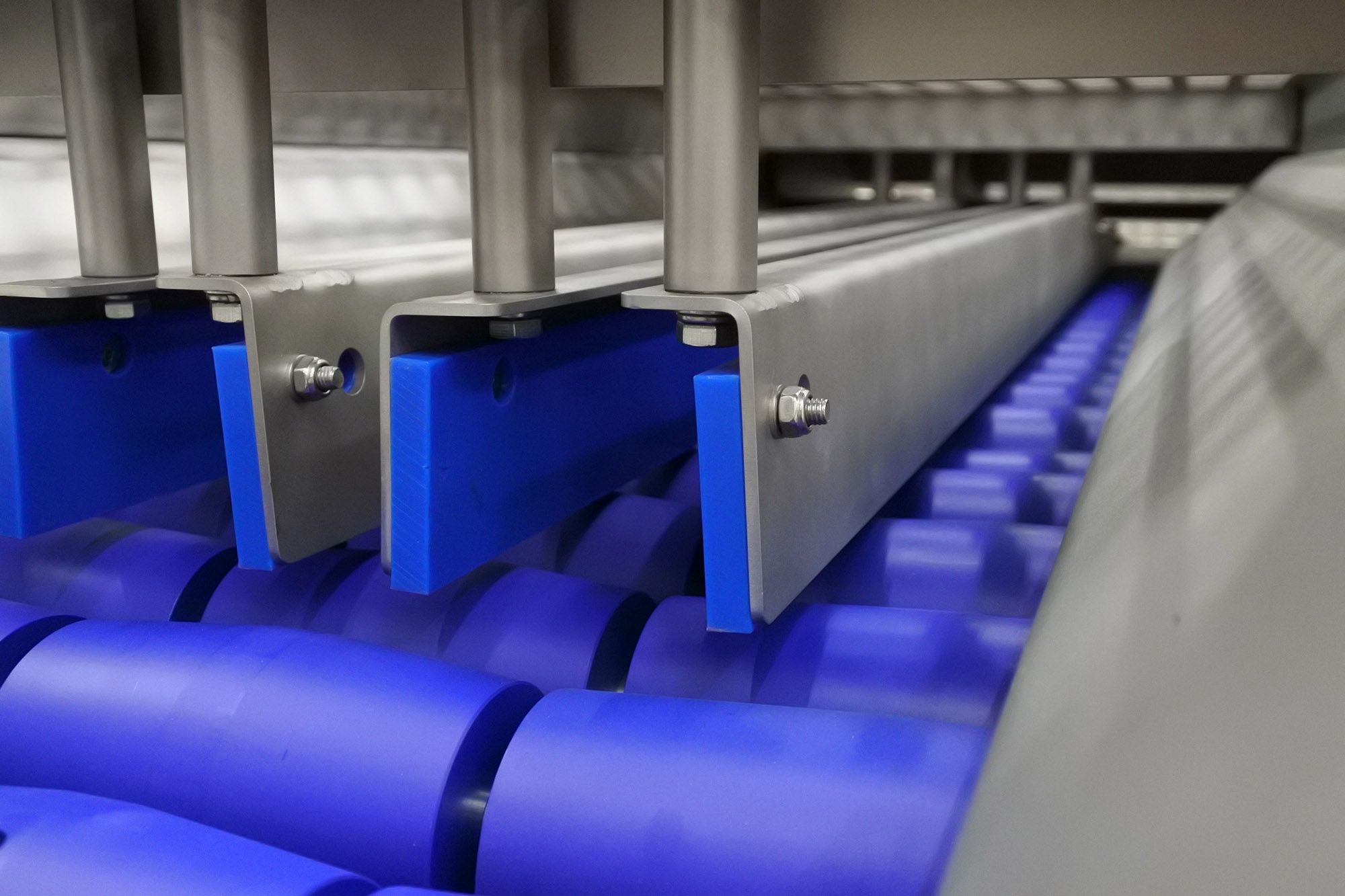

The optical grading machine is specially developed for the optical grading of peeled and unpeeled potatoes on defects, colour, size, shape and waste. This machine consists of a dosing unit, a roller belt, a camera unit and an ejection zone with the following exits. Due to the hygienic design and positioning of the cameras inside the machine, the product can be inspected 360 degrees without lens contamination occurring in the camera zone.

An innovative aspect of our optical Sorter is the fact that it blows out both good and bad product and allows product that needs to be peeled again to flow straight through. This way of working means that no bad product can end up in the good product stream. This machine is particularly suitable for steam peeled potatoes. Furthermore, the modular built up of the systems allows customers to grade potatoes in as many different categories as they like.

E.E: What estimations do you have for 2023?

S.V: Last year customer were hesitant to invest in new machinery due to the large uncertainty in the world regarding the war in Ukraine, the energy crisis that hit the whole of Europe and of course the aftermath of the COVID pandemic. However, this year we’ve noticed that customers are eager to move forward and increase and expand their businesses again. For us, this means that we’ve been of to a great start up this moment concerning large projects that came through and also the rest of year is also looking very promising.