UltraMax manufactures Lithium Iron Phosphate LiFePO4 batteries for golf trolleys, motorcycles, campervans, motorhomes, mobility scooters, wheelchairs, marine vehicles, uninterruptible power supply, solar energy storage battery packs, and so on.

UltraMax is one of the UK’s largest lithium battery manufacturers. The company specializes in manufacturing custom lithium batteries for commercial and domestic use.

Easy Engineering: What are the ranges of products and what types of services do you offer?

We have been in the business of making batteries for over 40 years, and so our product range offering is very extensive. Regarding our UltraMax brand – we manufacture lithium batteries that are used in different applications, the most common being caravans/ RVs/ motorhomes, solar energy storage, boats and yachts, electric wheelchairs and mobility devices, construction equipment, electric bikes, and EVs. Battery technology has advanced so much in the past decade, enabling us to fully customize our batteries to our customer’s convenience and make them more convenient and safe. As such, we have created the widest range of lithium LiFePO4 batteries available in the market. Our batteries can have or include prismatic/cylindrical/pouch cells, DIN terminals, Bluetooth, app-controlled monitoring, and/or a CAN bus communication system.

We extend to our customers after-sales support services that are available 5 days a week. All our batteries come with a full warranty and if you’re in the UK, shipping is free!

This year, we also launched the UltraMax ESS range of home storage ESS racks and systems, which is us expanding our product lines, both horizontally and vertically

E.E: Which are the most innovative products/solutions and what special features do they have?

Our most innovative products are our lithium LiFePO4 range. We are also currently working on integrating AI, Machine Learning, and IoT to develop newer battery technology in-house, to make lithium batteries safer, more accessible, and more convenient to use, across all applications.

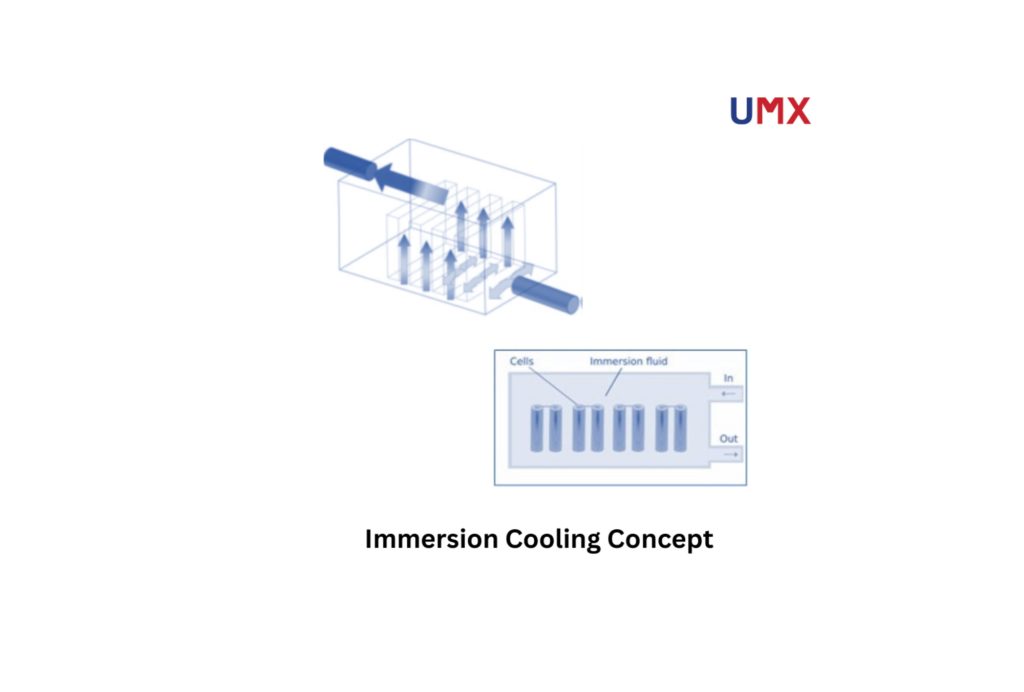

The ESS we are building will have all approvals from UK and EU regulatory authorities. We plan to leverage breakthrough immersion-cooled battery technology to make the BESS systems safer and to increase their in-service reliability.

E.E: How do your best products / solutions work?

The latest components are available in the market and we benchmark our designs against the latest technical advancements prevailing in the industry. We have a solid grounding concerning electro-mechanical software and IoT products. We find it important to capture the voice of our customers and ensure our products fit their requirements well. This ensures continuous improvement to our product line and user experience. We also prioritize quality control, with several engineers in our UK office checking product quality post-manufacture.

E.E: In what types of projects do clients use your products/solutions?

Our products are most used by people in their caravans/ RVs/ motorhomes, or solar energy systems. They are also used by users of mobility vehicles, golf carts, and electric bikes. The marine and construction industry also makes up a big part of our customer base. We are also getting involved in HV products in the Transportation and Energy Storage market. The ESS systems we are building have a power rating of 200 kW for residential use and light industrial usage.

E.E: How important is innovation / R&D in your field?

R&D is what has helped us innovate and effectively lead in this industry. As battery technology advances and becomes more accessible, continued focus on R&D will only bring in more creative technologies at a better rate. Our R&D team continues to listen to what our customers want and works to create battery solutions that benefit our customers. We have invested in an R&D-focused approach, to improve the safety and lifespan of the battery pack. Our R&D projects focus on developing a range of technology, to create and improve everything we manufacture, from BMSs to battery cooling. Our ESS system, for example our breakthrough immersion-cooled battery technology to make the BESS systems safer and to increase their in-service reliability.

E.E: How do your products /solutions increase profitability for users?

Our batteries are engineered for durability, reliability, and safety, providing consistent performance over an extended lifespan. This reduces the need for frequent replacements. The benefits of lithium batteries are well known; they have a high energy density compared to other battery technologies, allowing users to store more energy in a smaller and lighter package. However, we are building on this and developing our own technology to create batteries with increased safety and longer lifespan, with no significant increase in cost. Our lithium batteries are designed to be compatible with a wide range of devices and applications, offering versatility to users across various industries. All our batteries also carry a full warranty and after-sales support, which generally carries no extra cost.

E.E: How can clients sustainably use your products / solutions?

At UltraMax, we are developing several additional safety features in our Battery Management system and battery hardware to avoid any potential hazardous events. Having won the Faraday Battery Challenge, we are developing a battery pack with an extremely innovative cooling system that uses a biodegradable fluid. UltraMax is also developing recycled steel casing to replace ABS plastic cases. Additionally, for every customer to whom we supply our batteries, our goal is to establish a recycling system for those batteries with customers able to return them to us after use.

E.E: How is AI affecting your field of activity?

We are heavily investing in AI-based products, and have started development work on an AI-based battery energy storage system (BESS) which will employ novel fire mitigation and state-of-charge estimation algorithms. It will immensely benefit suppliers of BESS who plan to improve reliability and safety features within their products. As far as we know we are the only company and/manufacturer doing this in the UK.

E.E: How do you see the future in your field?

We see ourselves getting into higher voltage systems and fully integrated products with a greater focus on internally creating and manufacturing both the hardware and software of our battery products.

E.E: What are the business plans for 2024?

We have increased our engineering headcount substantially at the end of 2023 with further hires expected in 2024. We will aim to build on the multiple grant awards we have received in 2023. In the Faraday Battery Challenge we are focused on developing fully immersion-cooled battery packs across multiple sectors. On the software side, we aim- to develop our own BMS for our products, and in 2024, we aim to bring our technical expertise in-house, with our engineers currently focused on creating a full range of IoT products to cater to our core customer base.