DiLiCo engineering is an international supplier of high-quality measurement technology for the use in fuel cells, redox flow batteries, electrolyzers, and batteries. DiLiCo engineering’s measurement technology provides information that makes energy systems more reliable, durable, and cost-effective. We support our customers in optimizing operational management and in the analysis of cell components and stacks.

Furthermore, DiLiCo engineering is active in demonstrator and laboratory applications project planning for hydrogen solutions. Last year, the company managed a project in which an energy container for the supply of hydrogen consumers was set up in a hydrogen village. This site is located in Bitterfeld, Germany and is open to the public.

Easy Engineering: What are the main areas of activity of the company?

DiLiCo: DiLiCo engineering’s main activities are divided into the three areas: (1) development and distribution of DiLiCo measurement technology, (2) distribution of the 5kW fuel cell combined heat and power plant (CHP) inhouse5000+ for a sustainable and economic energy supply for buildings, as well as (3) demonstrational project planning in the field of hydrogen and fuel cell technology for research and industry.

E.E: What’s the news for 2020 about new products?

DiLiCo: In the field of measurement technology, DiLiCo engineering is extending its DiLiCo cell voltage product line this year to include a low-cost version for cell voltage measurement on galvanic cells for serial use in fuel cells, electrolyzers, and batteries. The high-precision standard version of DiLiCo cell voltage will, of course, still be available and is aimed at customers from the field of research and development who require particularly precise information for cell voltage monitoring at each individual cell.

Furthermore, DiLiCo engineering is working in collaboration with the Hydrogen and Fuel Cell Center ZBT in Duisburg on an universally applicable contacting solution for fuel cells and electrolyzers. The goal is to mount a single-cell voltage measurement to the stack within a few minutes.

Within the scope of fuel cell CHP distribution, the first 5 kW fuel cell CHP, inhouse5000+, will be commissioned in Magdeburg, the home of DiLiCo engineering, in 2021 in combination with an electric charging station. The inhouse5000+ system can already be operated with pure hydrogen and is currently undergoing field tests in the Energy Pavilion in Bitterfeld, Germany.

E.E: What are the ranges of traded products?

DiLiCo: DiLiCo engineering offers two product series for monitoring and analyzing galvanic cells, i.e., energy converters such as fuel cells, electrolyzers, and redox flow batteries, as well as energy storage devices, e.g., batteries. DiLiCo cell voltage is used to monitor the cell voltage at each individual cell. Fuel cells and electrolysers can consist of more than 400 individual cells. The cells are normally connected in series, so that the failure of a single cell will not allow for the continued operation of the remaining, but functional cells. Therefore, DiLiCo cell voltage is used to measure the cells quickly and with high accuracy, so that the information about a critical condition has already been transmitted to the plant control system before a possible cell failure occurs. DiLiCo cell voltage thus avoids failure and maintenance costs of galvanic energy systems.

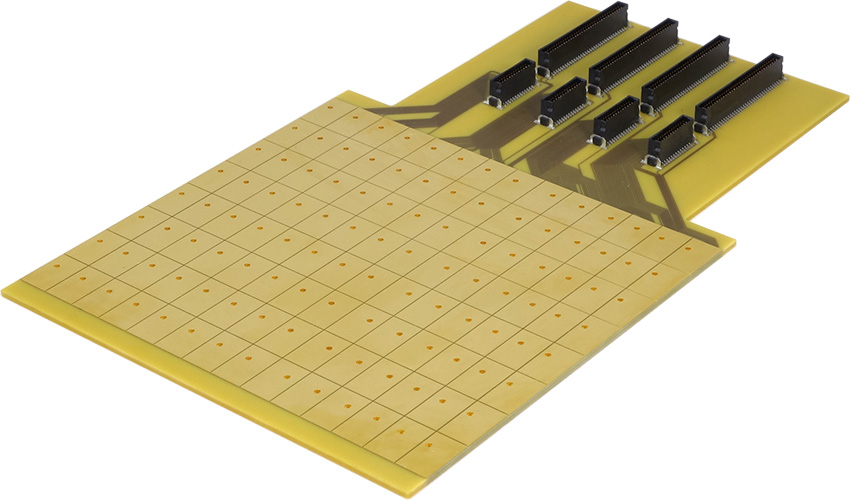

The second product series DiLiCo current density is used in research and development and measures the spatially resolved currents and temperatures along the area between two cells and within the fuel cell, the electrolyser, or the redox flow battery. This analytical measuring device can thus record the activity of electricity production over the cell surface with high precision. In a standard system, a cell area of 25 cm² includes up to 48 sensors for current and 48 sensors for temperature measurements. Cell areas of up to 800 cm² can be developed for individual customers. DiLiCo current density is used for the evaluation of the operation management and single components in which a hydrogen and air gas supply takes place such as membranes, gaskets, and bipolar plates. DiLiCo current density provides a deep insight into the cell and allows statements on the condition of the fuel cell and the electrolyser.

Moreover, DiLiCo engineering distributes the fuel cell CHP inhouse5000+ with an electrical output of 5 kW and a thermal output of 7.5 kW exclusively in the federal state of Saxony-Anhalt. The system is unique in Europe in its performance class with the use of fuel cell technology.

E.E: At what stage is the market where you are currently active?

DiLiCo: DiLiCo engineering acts as a supplier and developer of measurement technology in the market of technologies for fuel cells, electrolysers, and batteries. This market is on an upward trend worldwide because more and more governments see the hydrogen economy as the basis for a sustainable, efficient, and economic alternative to fossil-fuel-based energy, while industrial players are increasingly forced to switch to a sustainable energy supply. Currently, the market is still very much dominated by research and development. However, in the coming years, the political framework conditions that have already pushed for the expansion of renewable energy such as wind power and photovoltaics in Germany will lead the hydrogen sector to develop in a similar way. The hydrogen strategy adopted by the EU and Germany will allow the market to grow even more strongly in the future. Therefore, DiLiCo engineering assumes an increase in demand for measurement technology.

E.E: What can you tell us about market trends?

DiLiCo: Within the framework of sector coupling, i.e., the linking of energy producers, energy storage, and energy converters, the demand for hydrogen from electrolysers will be the first to increase. The energy distribution of hydrogen in pipelines is being intensively researched so that the existing natural gas infrastructure can continue to be used. Hydrogen distribution is the prerequisite for the safe supply of hydrogen to end users in the transport, building, and industrial sectors. In these areas, a gradual increase in fuel cell vehicles and filling stations as well as fuel cell cogeneration plants for the electrical and thermal energy supply of buildings will follow.

For DiLiCo engineering, the focus in this context is mainly on advancing and adapting the DiLiCo measurement technology from the requirements placed by research to industrial application conditions as a serial manufactured product.

E.E: What are the most innovative products marketed?

DiLiCo: In the field of measurement technology for electrochemical energy converters, ground-breaking innovations are still pending. DiLiCo engineering is constantly working on new innovative solutions to bring measurement technology to a new price level for the upcoming serial production for industrial applications. Thus, DiLiCo engineering can serve both customer groups and offer products for low-cost serial production as well as high-precision measurement technology for the high demand of accuracy in research.

E.E: What estimations do you have for 2020?

DiLiCo: The last weeks and months have shown that transitioning to sustainable energy production, distribution, and efficient consumption will no longer work without hydrogen, electrolysis, and fuel cells technologies. Therefore, the prospects for DiLiCo engineering as a supplier of measurement technology for the next as well as coming years have been assessed as very positive. The inquiries for DiLiCo measurement products are increasing as is the demand for research projects and engineering services in the hydrogen sector.